Hexagonal and ditrigonal mixed channel contact-heat-resistance-free heat transfer element

A double triangle, mixed channel technology, applied in tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as increased contact thermal resistance, fracture, poor performance, etc., to achieve improved heat transfer performance and good heat transfer performance , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

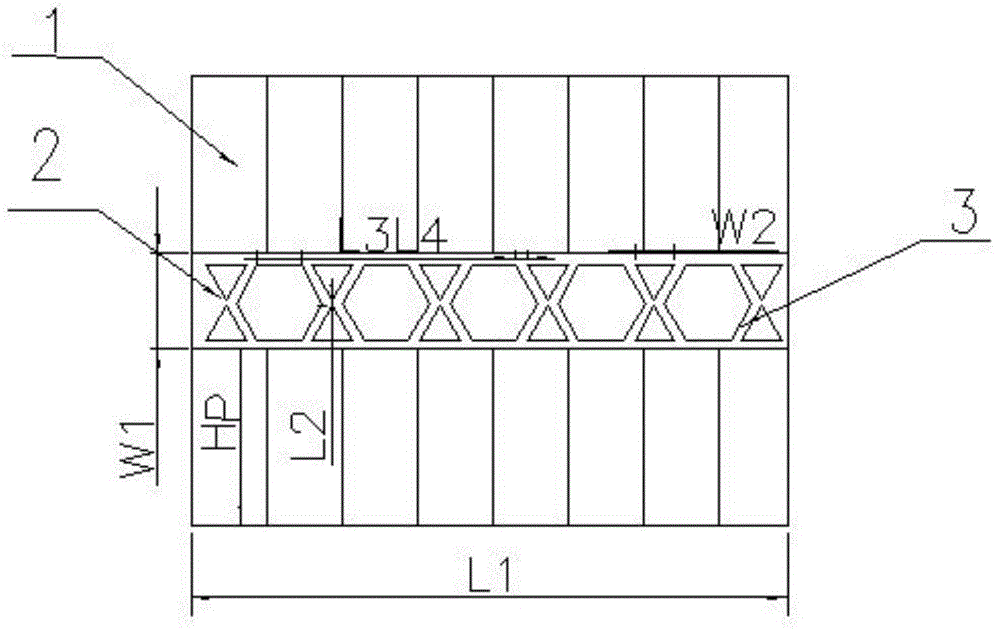

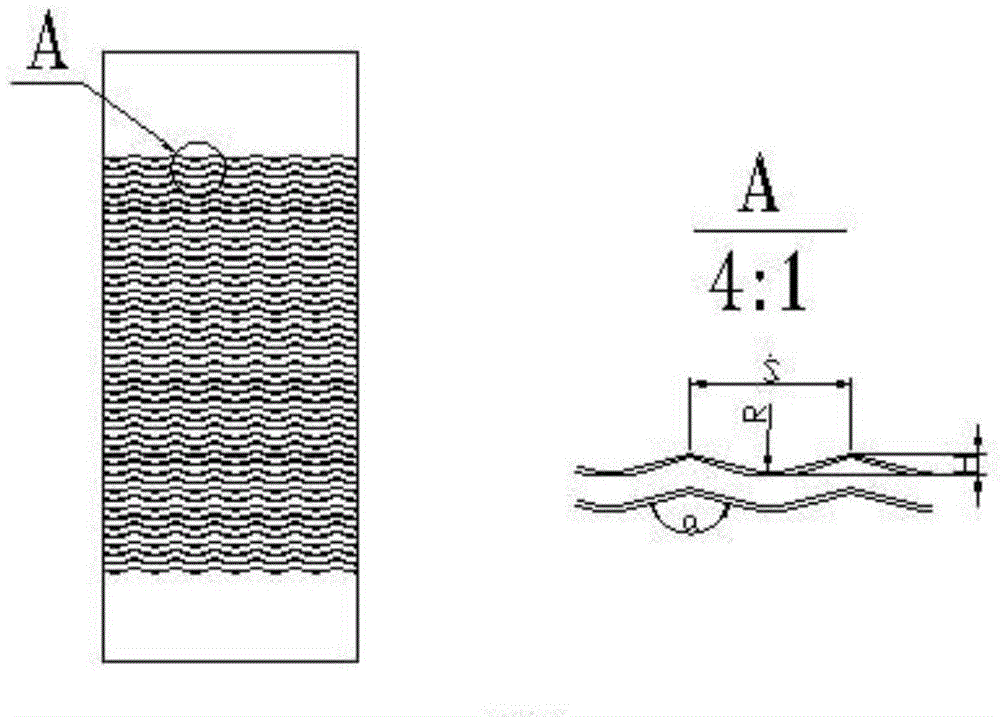

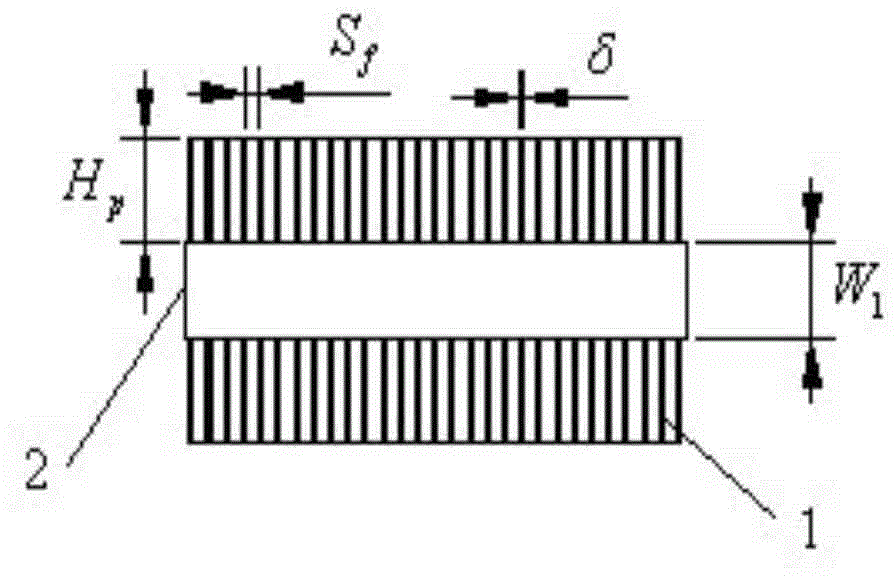

[0013] Such as figure 1 , 2 . The non-contact thermal resistance heat transfer element of the present invention shown in 3 is composed of heat dissipation fins 1 and heat transfer flat tubes 2. The heat dissipation fins 1 and heat transfer flat tubes 2 are integrated. The heat dissipation fins 1 Located on the upper and lower sides of the heat transfer flat tube 2, the heat dissipation fins 1 on the upper and lower sides are corrugated, the heat dissipation fins 1 are perpendicular to the heat transfer flat tube 2, and the distance between the heat dissipation fins 1 is S f , the thickness of cooling fin 1 is δ, and the height is H p , the wavelength of the corrugated fin 1 is S, the wave height is H, and the section thickness of the heat transfer flat tube 2 is W 1 , with a width of L 1 , several double-triangular and hexagonal passages that are not connected to each other are evenly arranged in the heat transfer flat tube 1 along the axial direction, and the number of pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com