A heat dissipation structure of a high-voltage and high-current vacuum circuit breaker

A vacuum circuit breaker and heat dissipation structure technology, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve the problem that the rated current parameter is not easy to increase, etc., to reduce contact thermal resistance, improve convective heat transfer coefficient, and increase heat dissipation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments of the high-voltage vacuum circuit breaker with high rated current level given in the accompanying drawings.

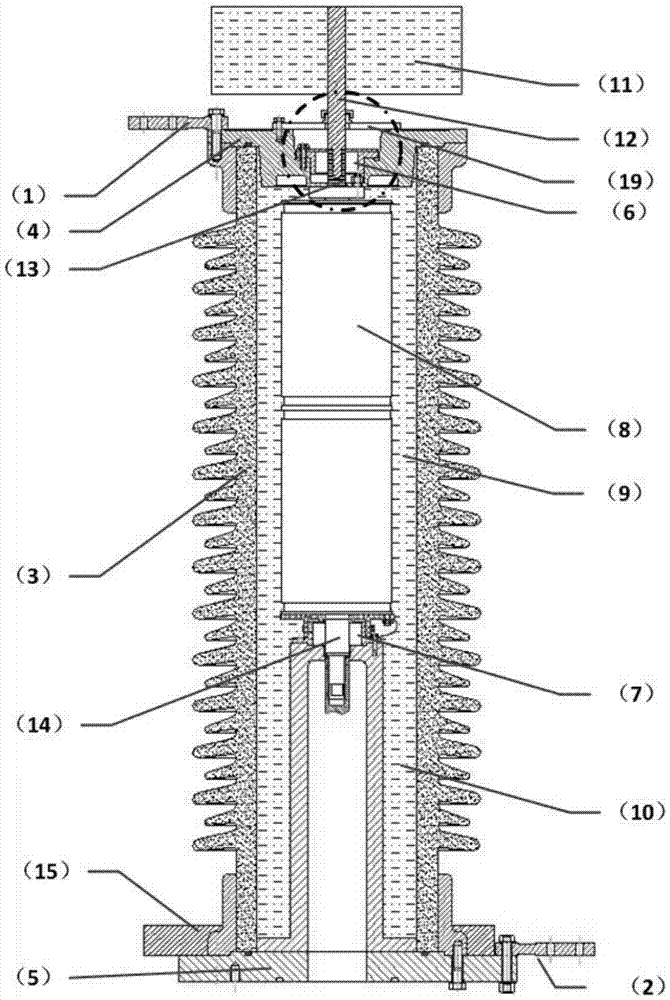

[0019] The pole structure of the vacuum interrupter of the high voltage vacuum circuit breaker of the present invention is as follows: figure 1 and figure 2 shown.

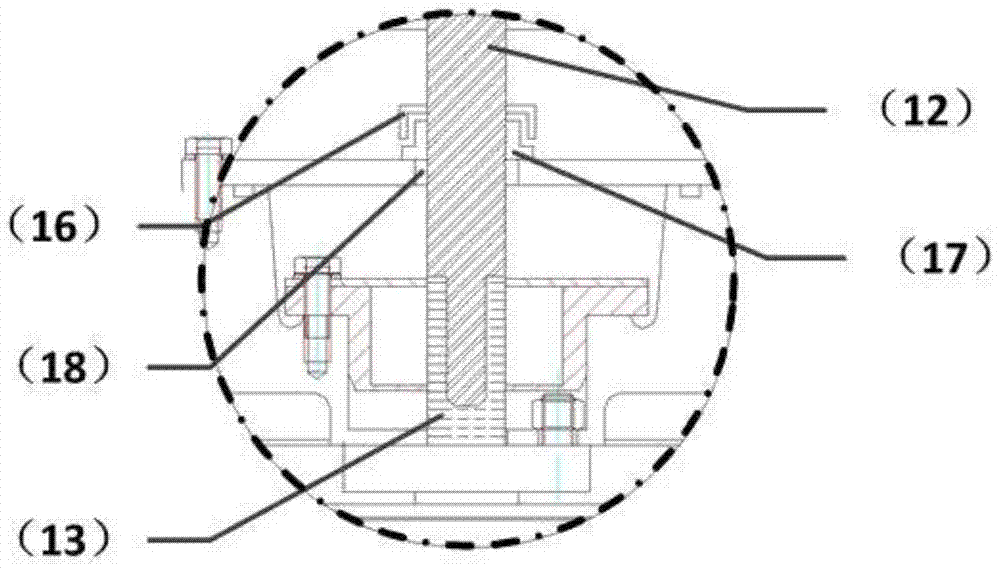

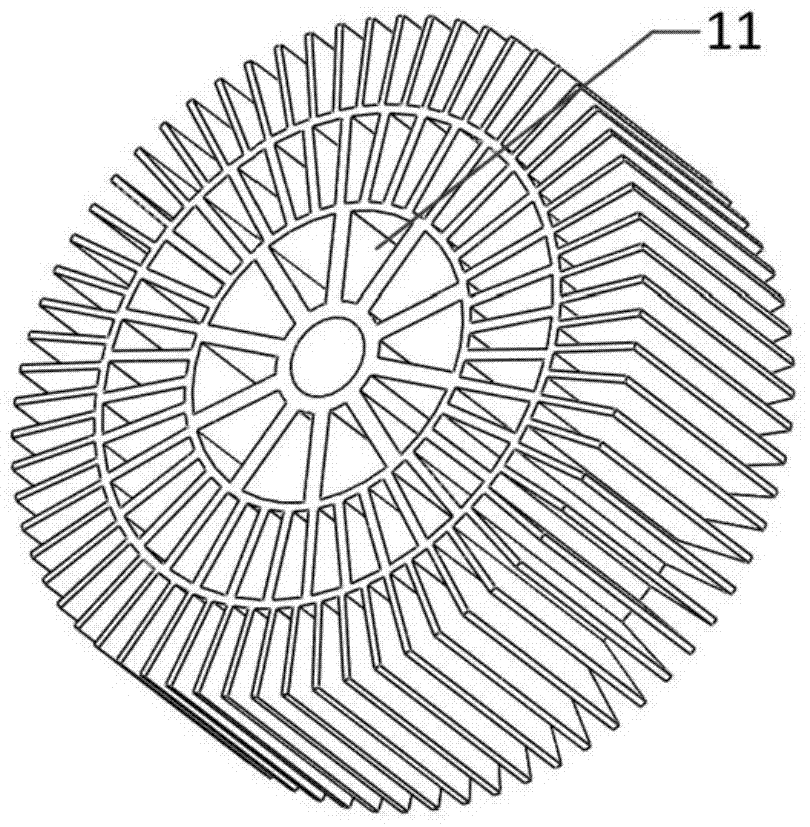

[0020] The upper terminal 1 and the upper flange 4 are connected by bolts, the upper flange 4 is softly connected with the static conductive rod 13 through the upper conductive contact finger 6, and the static conductive rod 13 extends into the vacuum interrupter 8 to meet the dynamic and static contacts. Connection, the moving contact is connected with the moving conductive rod 14, connected to the lower conductive support 10 through the lower conductive contact finger 7, and then connected to the lower flange 5, the lower flange 5 is cast with a fin radiator 15, and connected to the lower terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com