Patents

Literature

100results about How to "Increase the rated current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

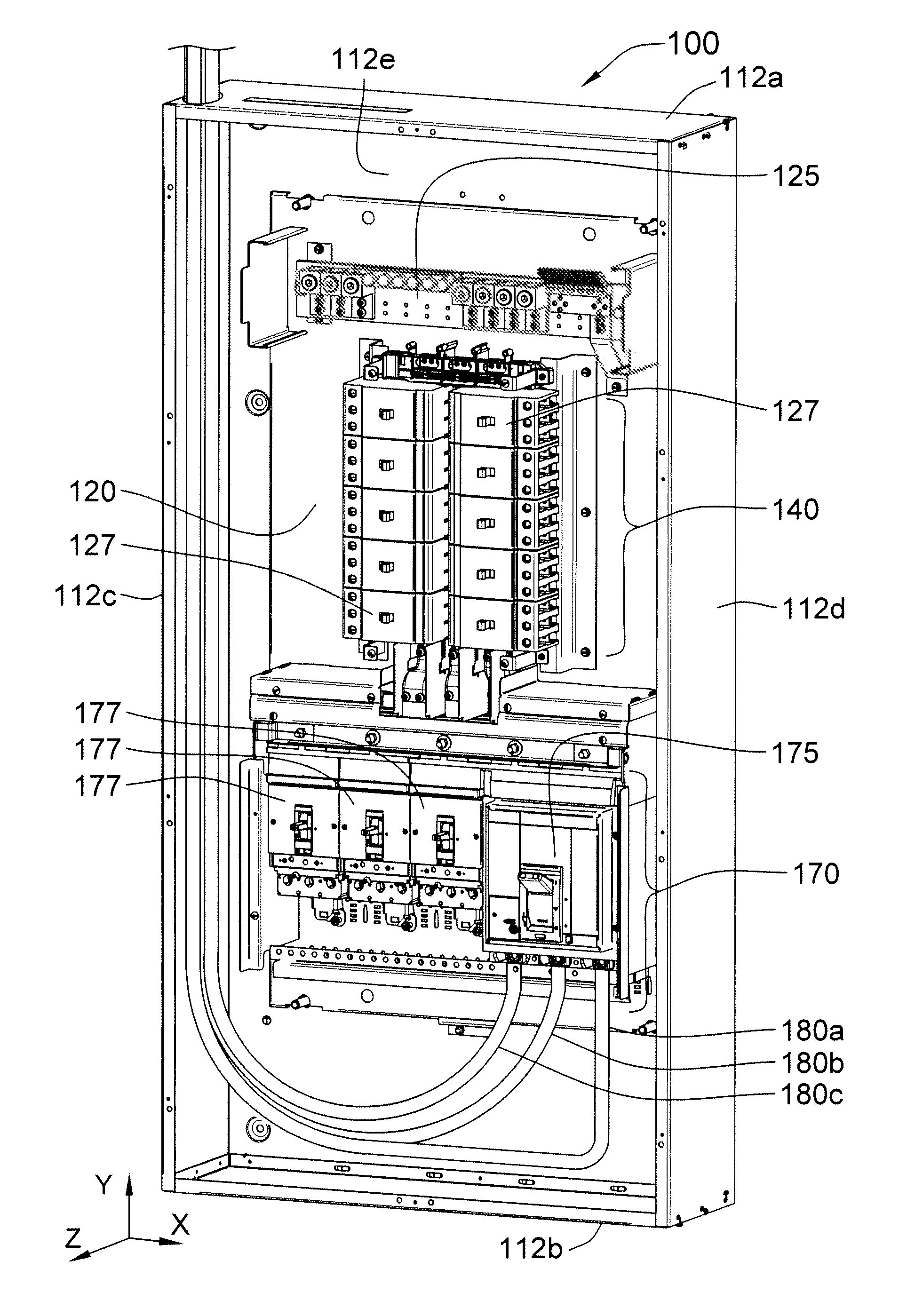

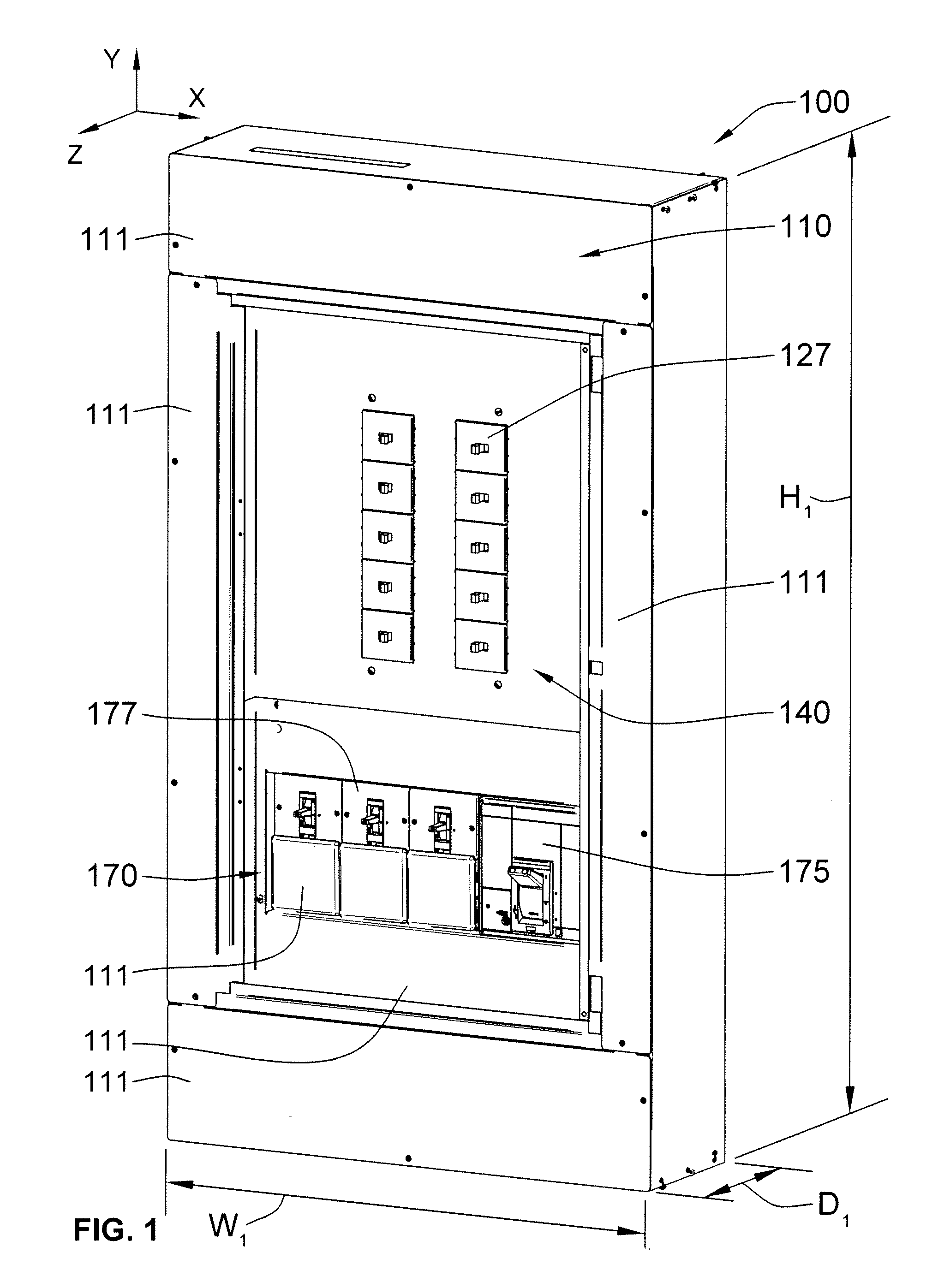

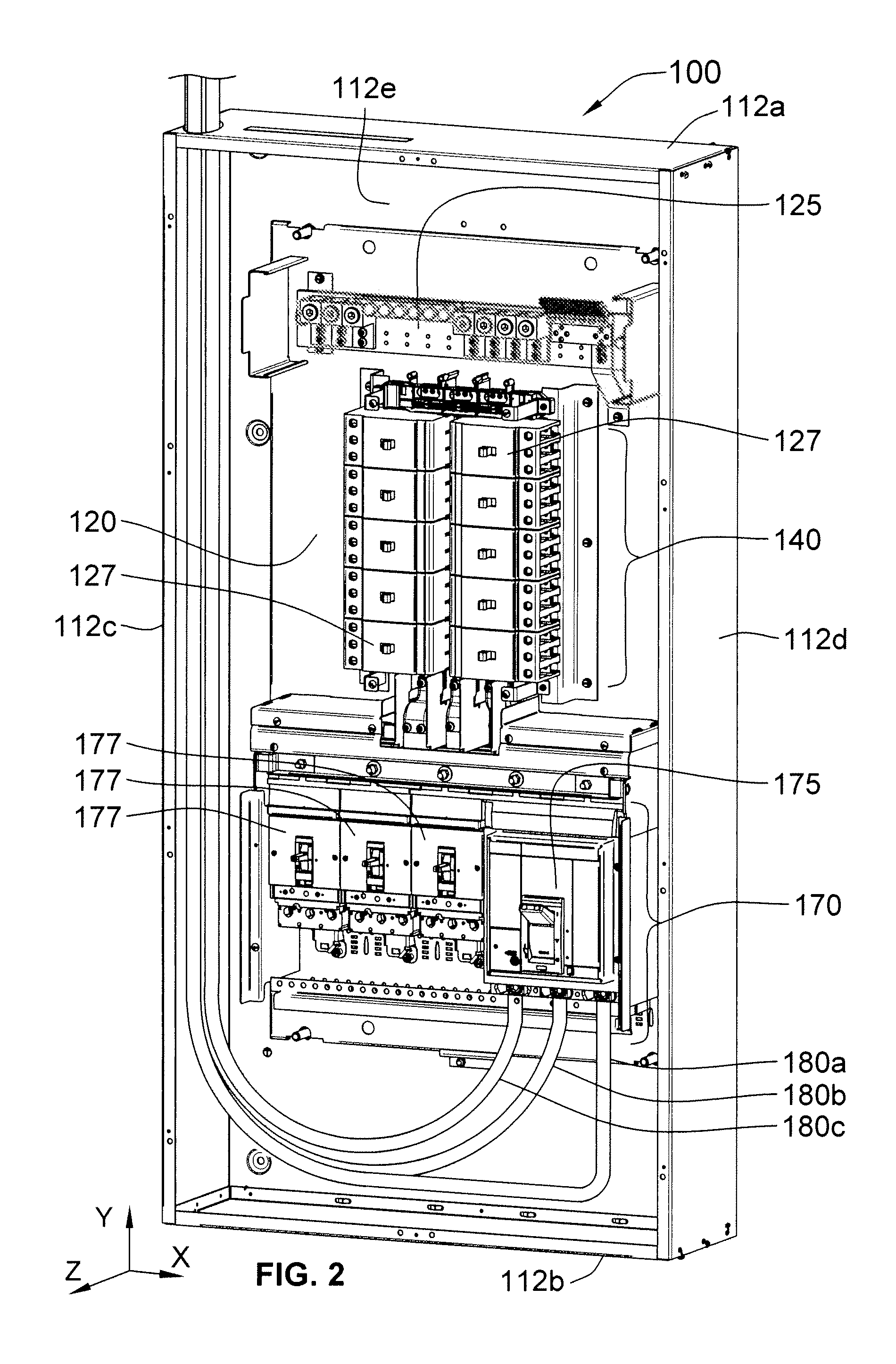

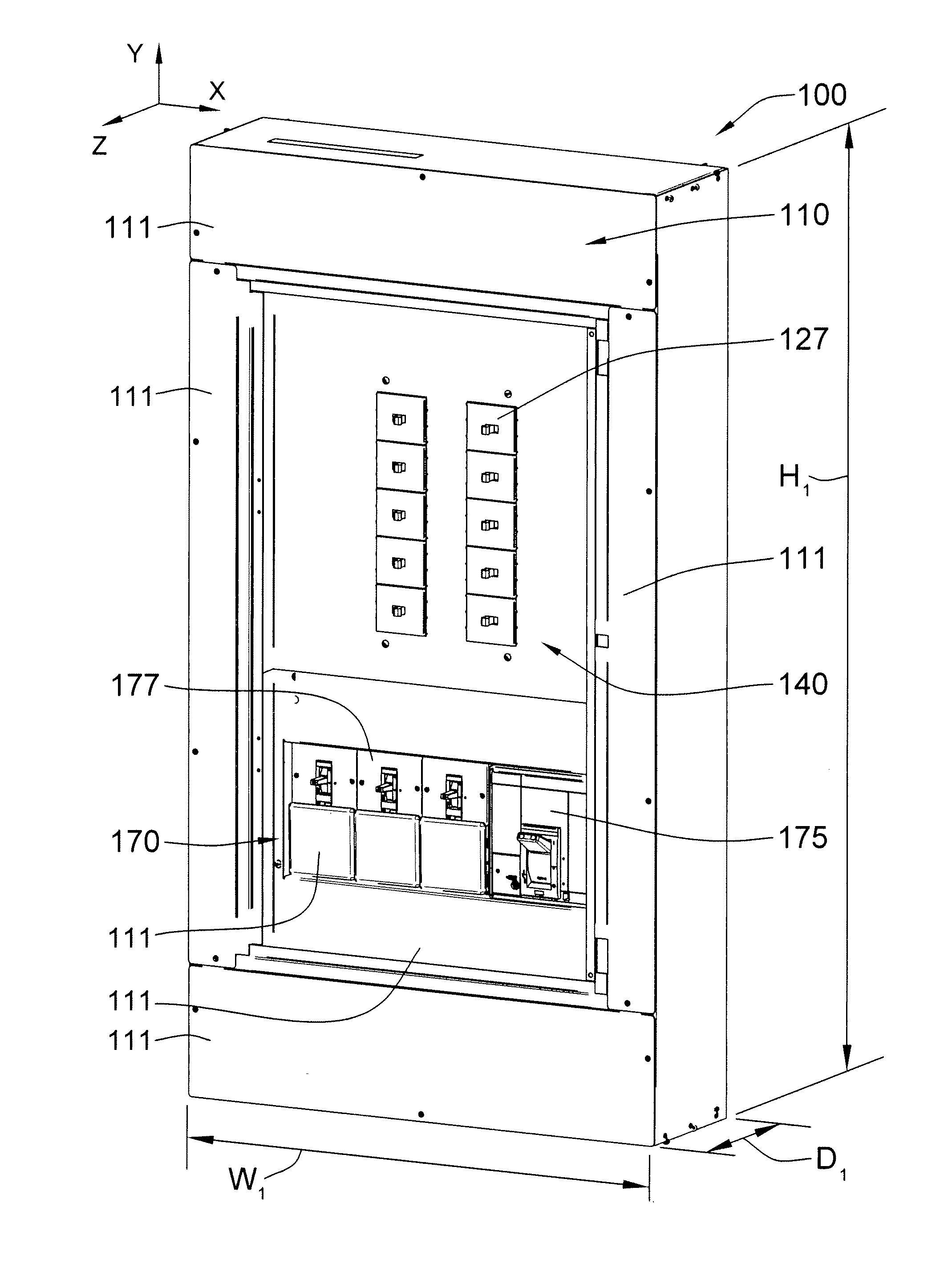

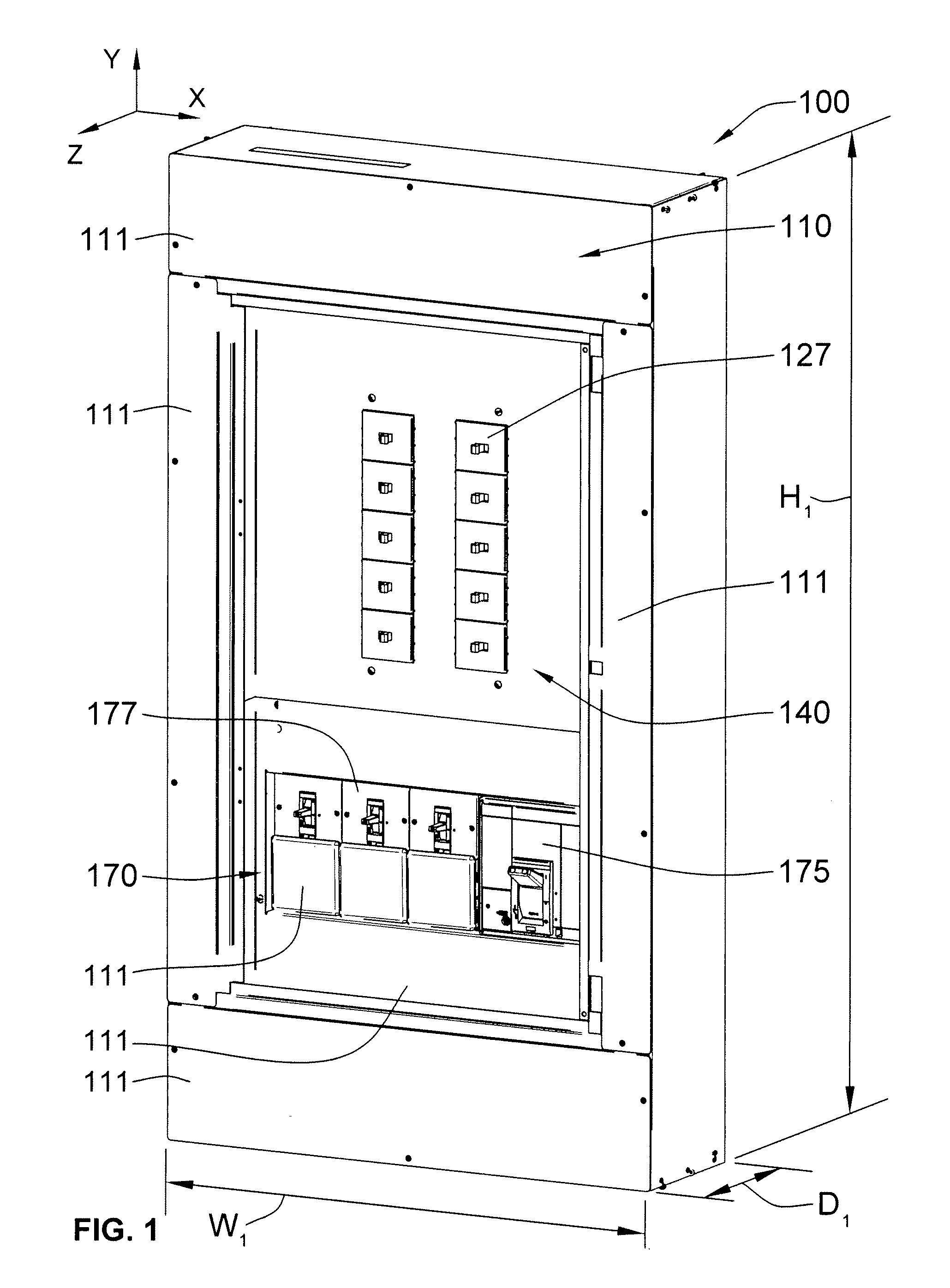

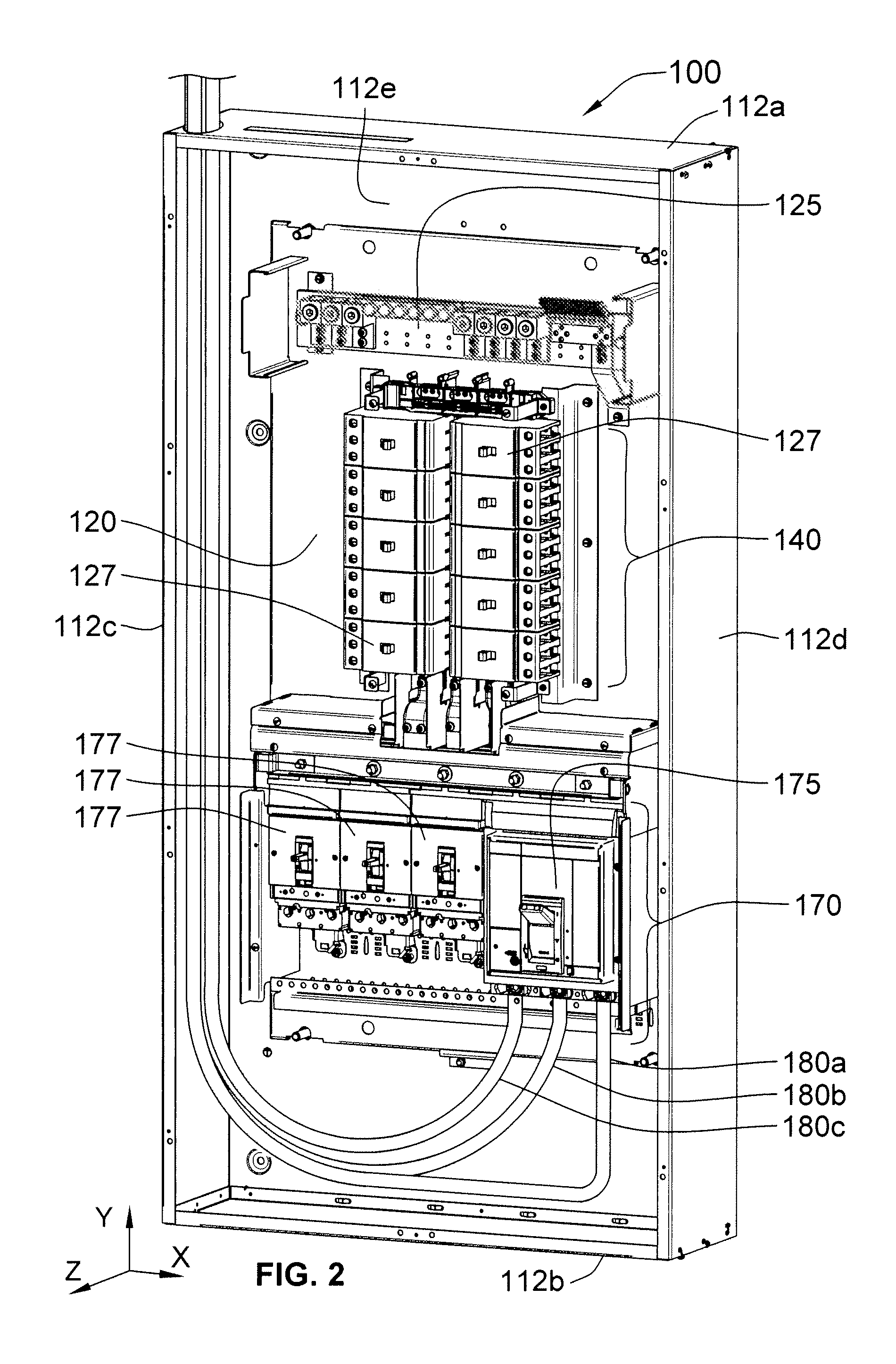

High density power/lighting panelboard

ActiveUS8305739B2Expanded ampacity rangeIncrease the rated currentBus-bar/wiring layoutsSubstation/switching arrangement casingsElectricityHigh density

A panelboard supplies electricity to multiple loads, such as lighting fixtures and / or other electrical devices via one or more high-amperage circuit breakers and one or more low-amperage circuit breakers. The panelboard includes one or more vertical busbars and one or more horizontal busbars coupled together in a single housing. The one or more horizontal busbars are coupled to a main input breaker that receives electricity from a source. The main input breaker distributes the electricity to the horizontal busbars. The horizontal busbars distribute the electricity to the high-amperage circuit breakers coupled thereto and to the vertical busbars. The vertical busbars distribute the electricity to the low-amperage circuit breakers coupled thereto.

Owner:SCHNEIDER ELECTRIC USA INC

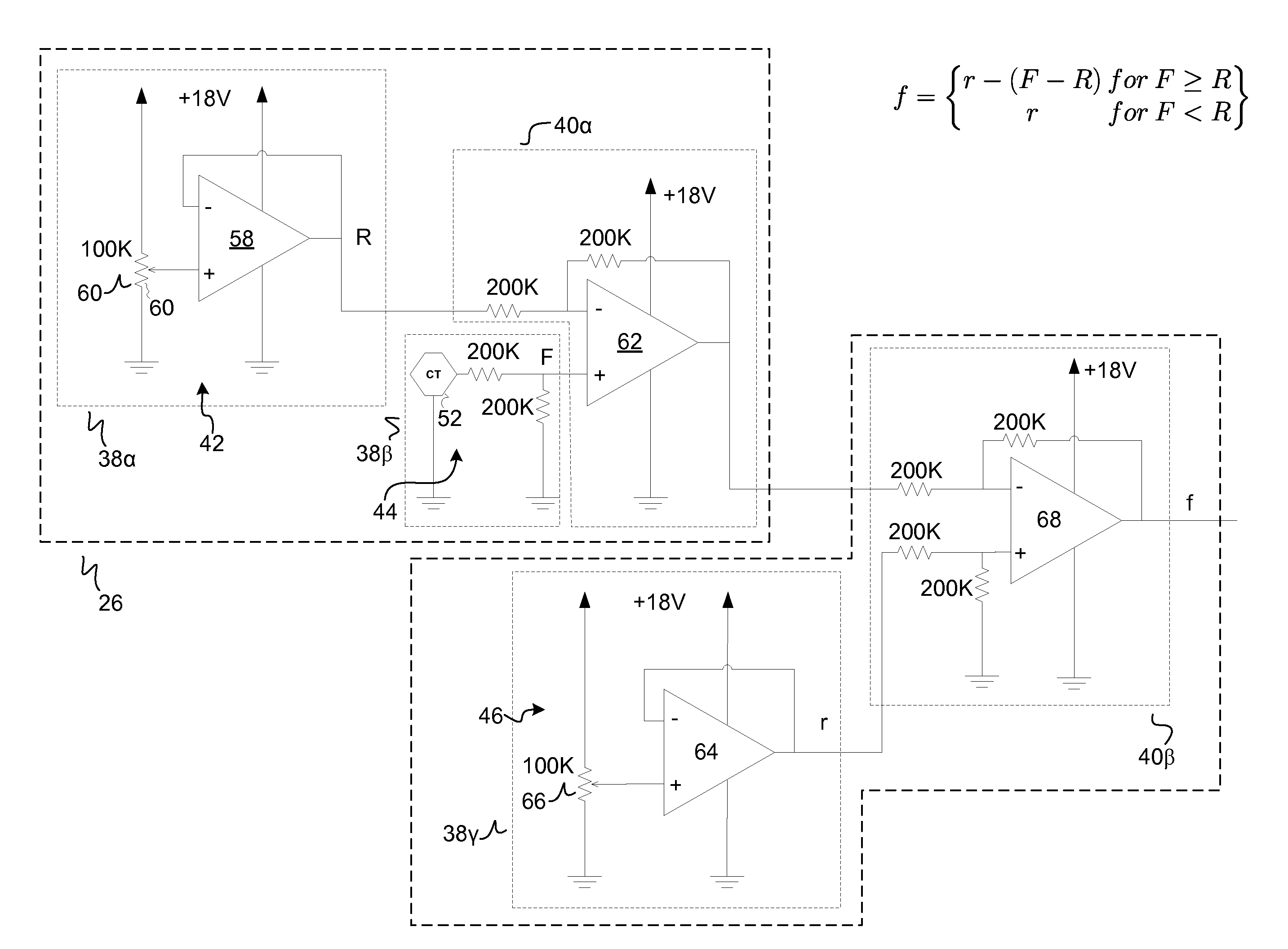

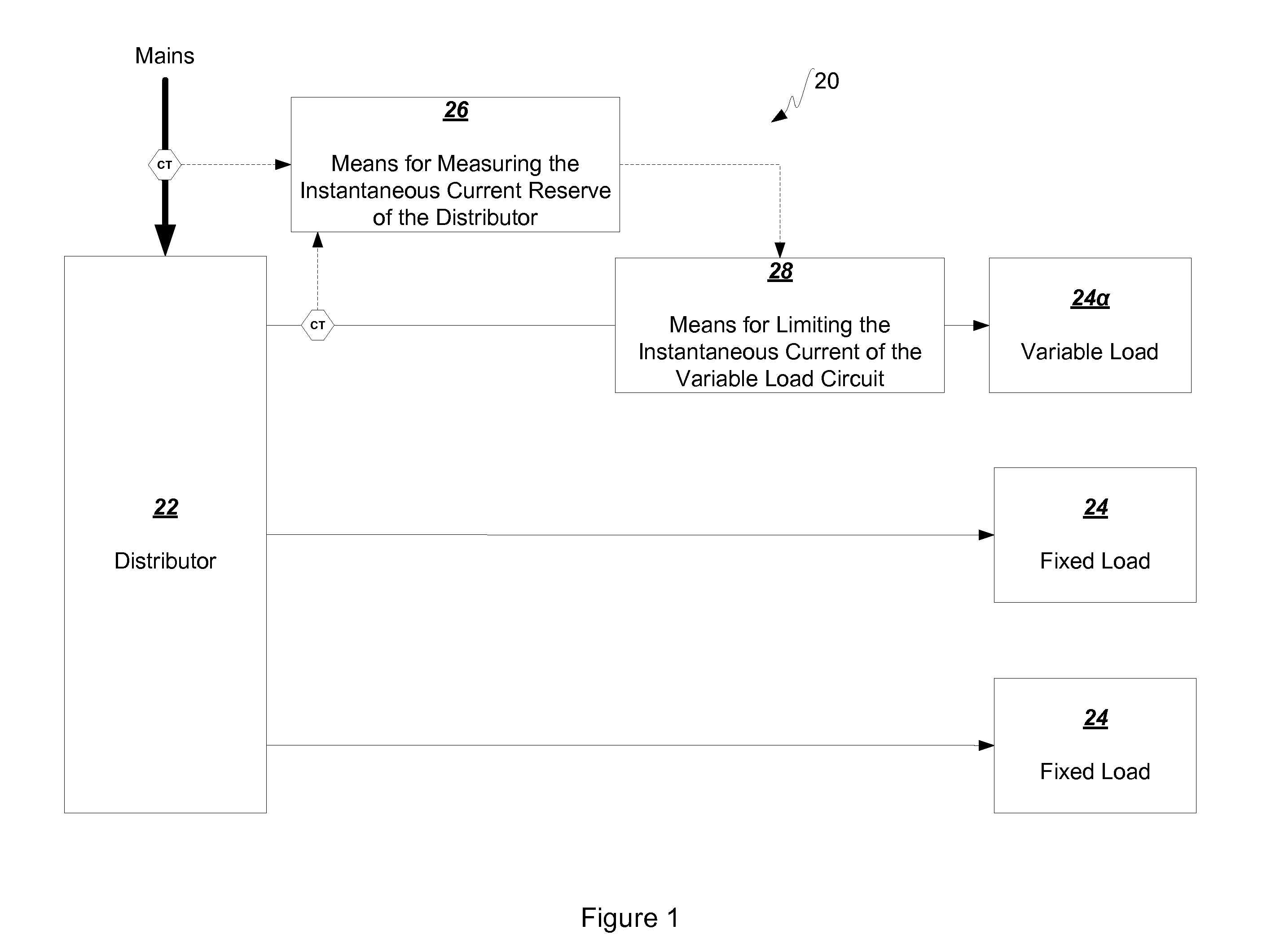

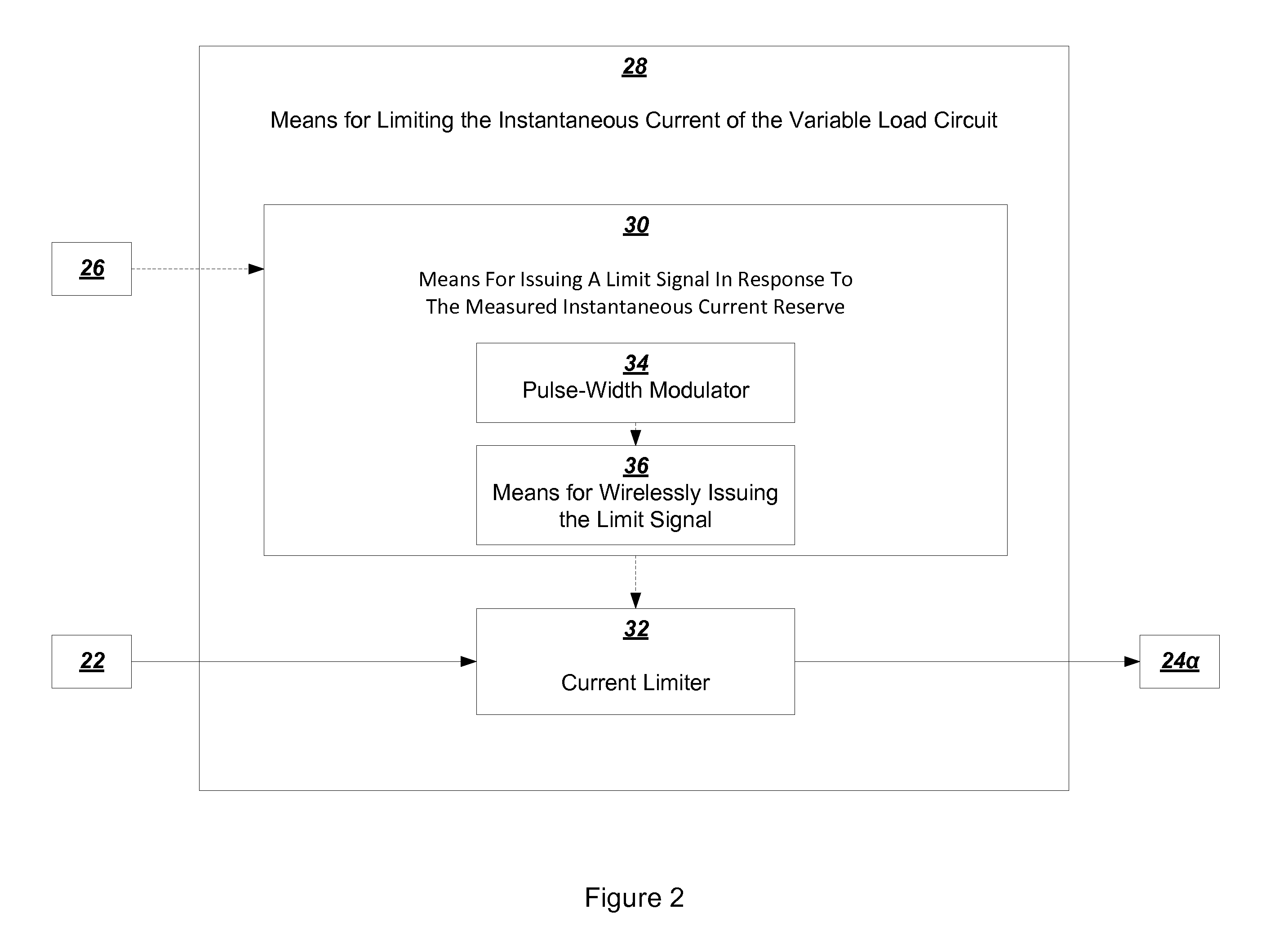

Method and Apparatus for Allocating Electricity from a Distributor

ActiveUS20100066170A1Increase freedomIncrease the rated currentDc network circuit arrangementsPower network operation systems integrationElectricityLoad circuit

The present invention provides a method and apparatus for allocating current (20) from a distributor (22), having a maximum rated current, among a plurality of load circuits (24), including a variable load circuit (24α) that benefits from a full load current allocation but is operable at a lower current allocation. The invention provides for measuring the instantaneous current reserve of the distributor (22) as the maximum rated current of the distributor (22) less the instantaneous current flowing from the distributor (22) to the plurality of load circuits (24), and limiting the instantaneous current of the variable load circuit (24α) to the full load current of the variable load circuit (24α) if the instantaneous current reserve is greater than zero, and the sum of the full load current of the variable load circuit (24α) plus the instantaneous current reserve, if the instantaneous current reserve is less than or equal to zero.

Owner:SCHULER MIKE

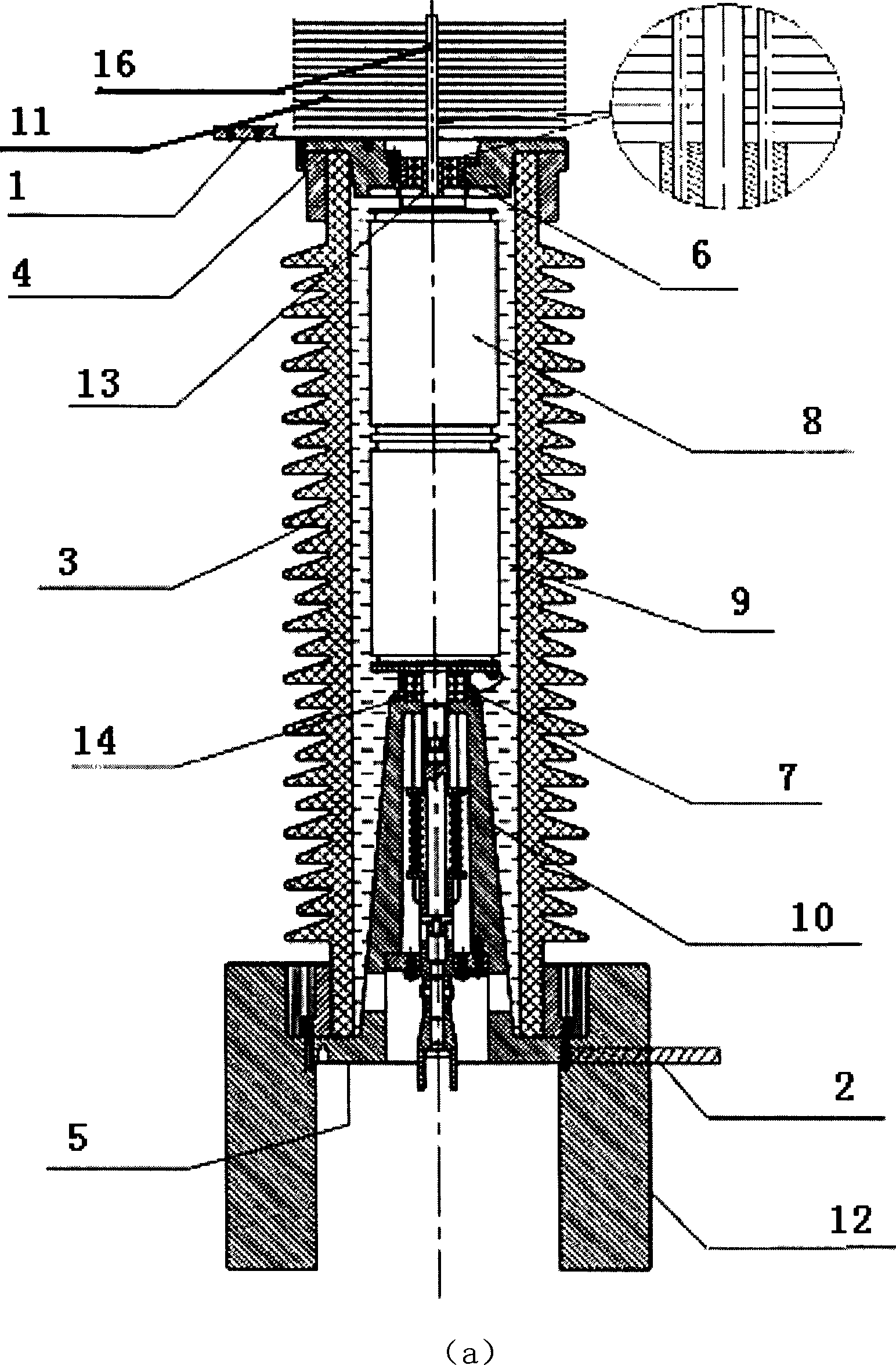

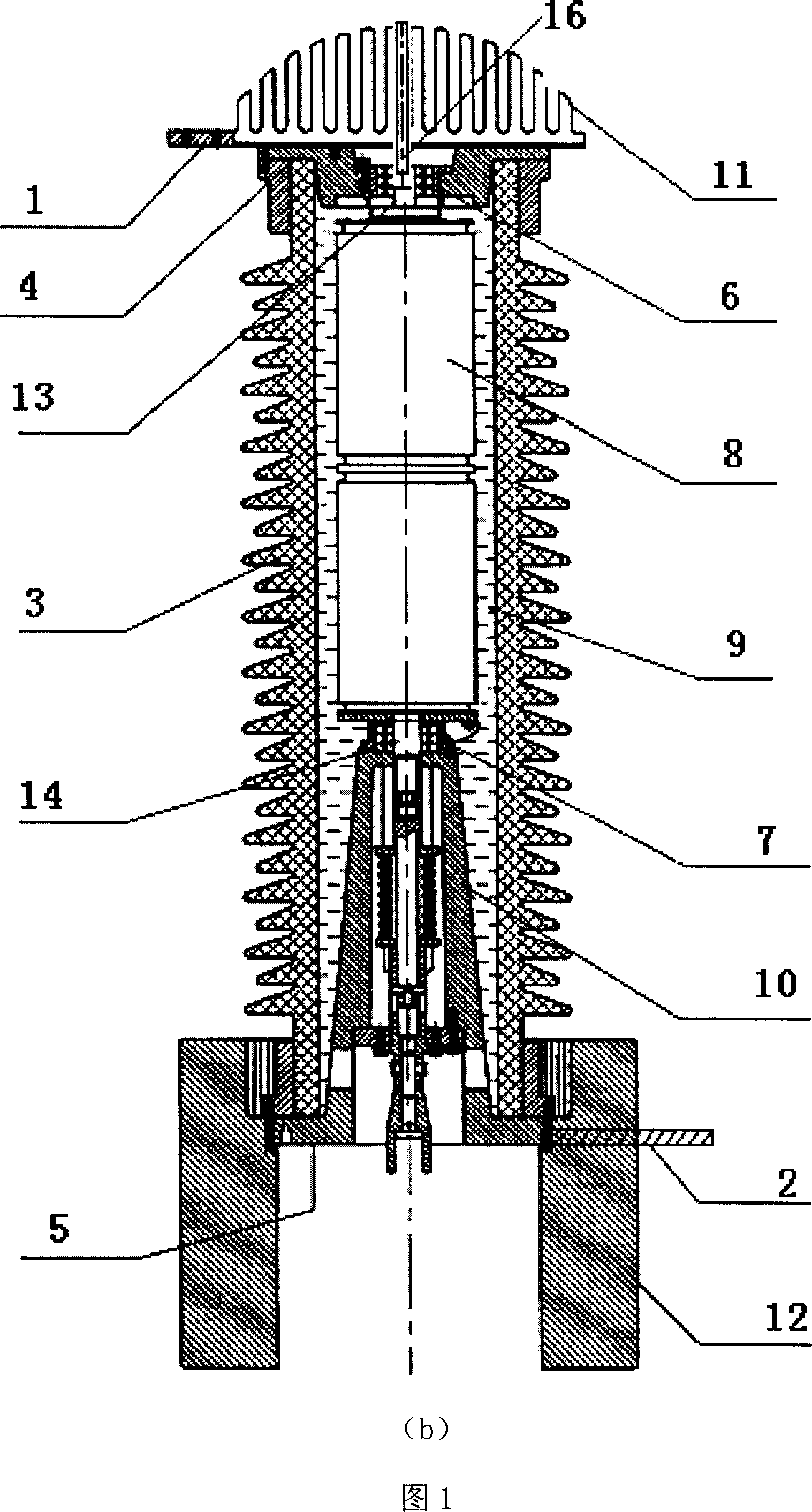

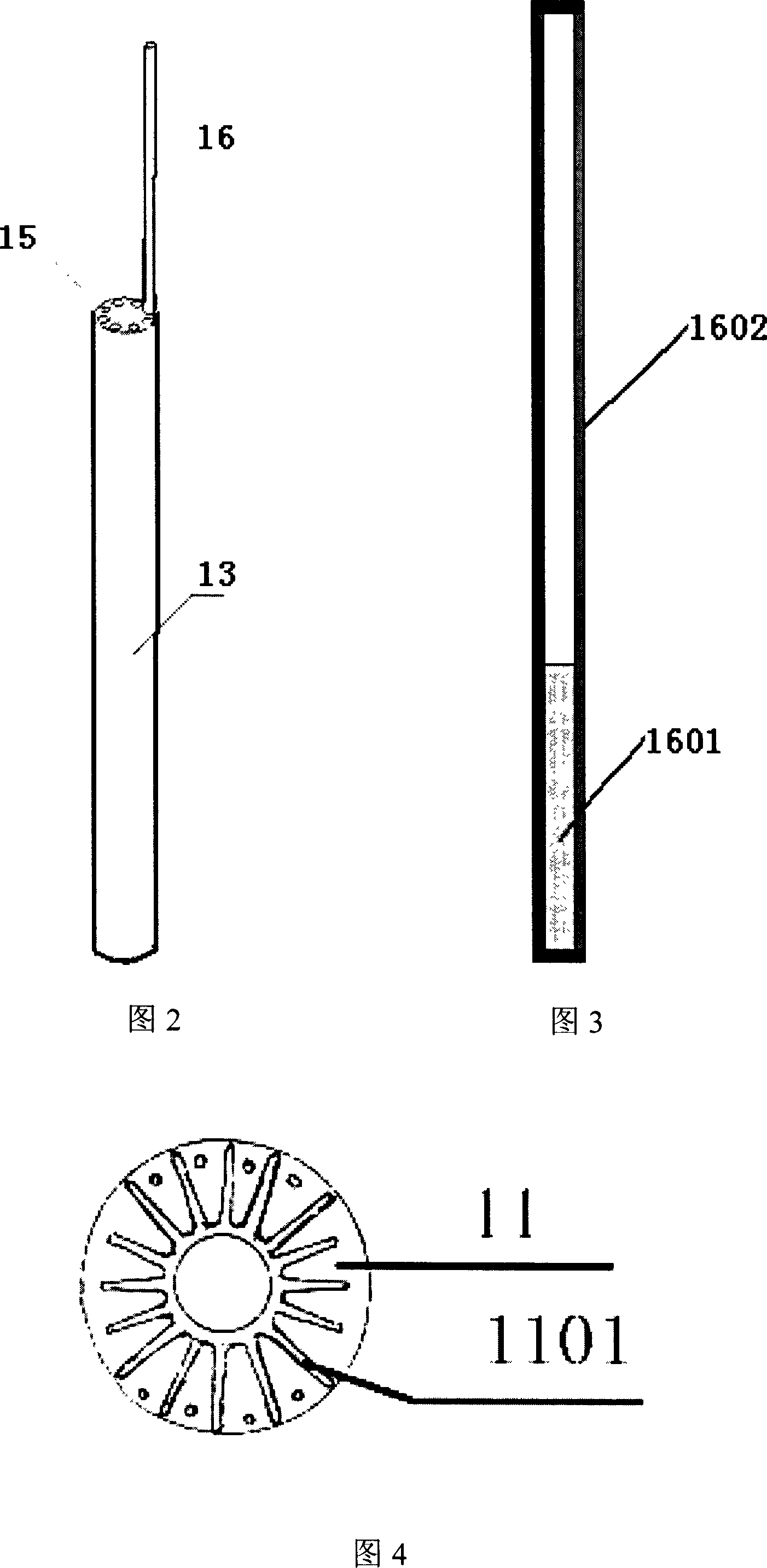

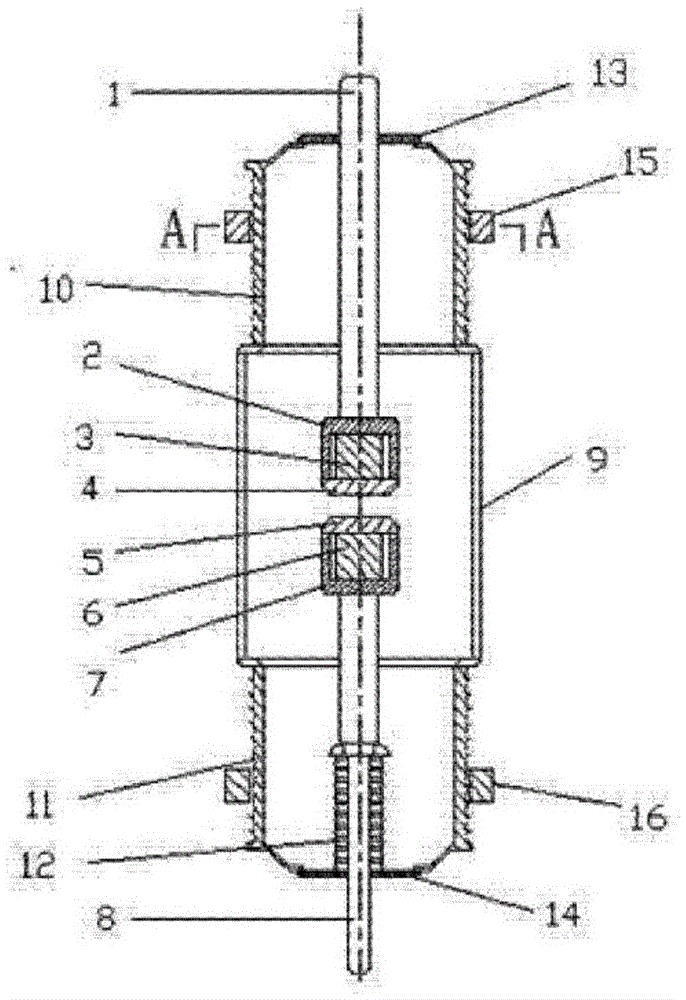

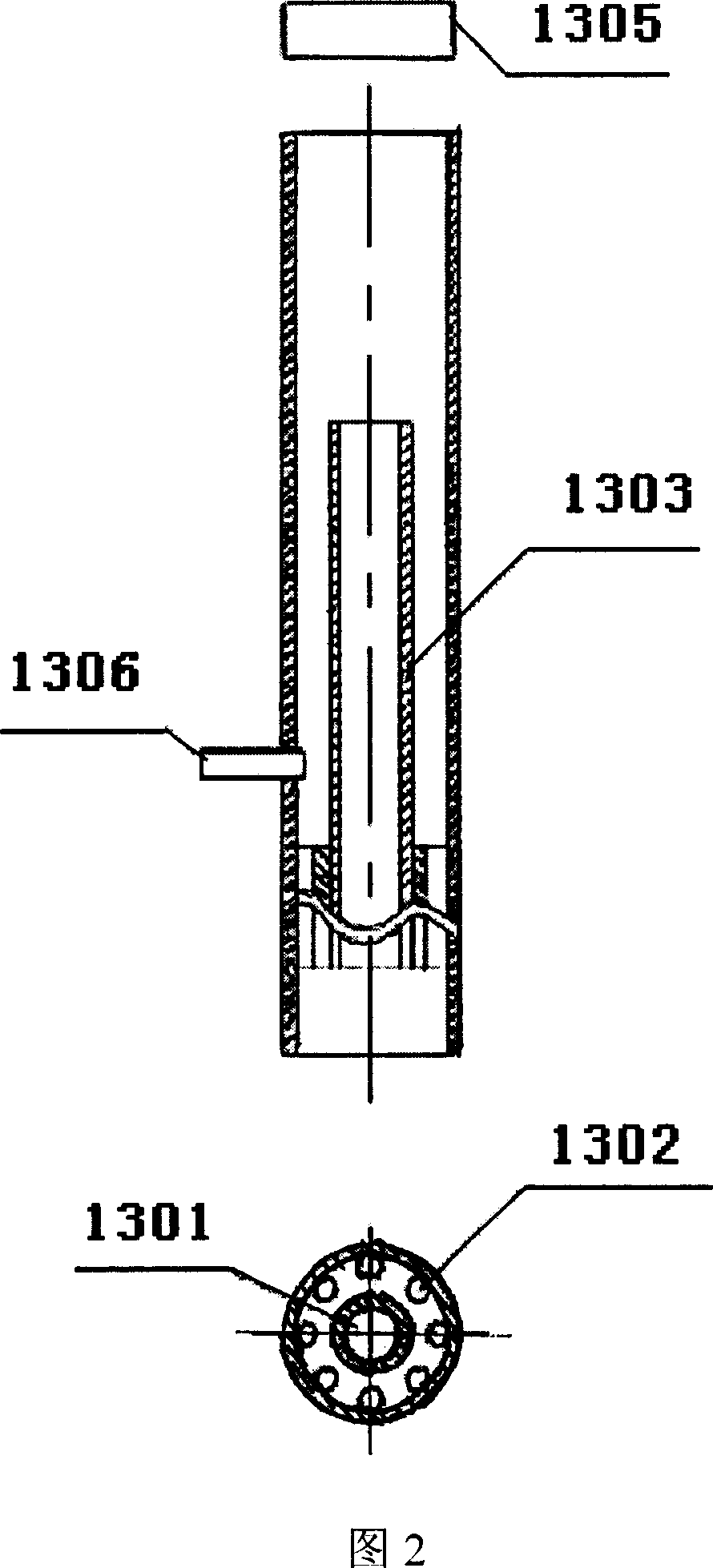

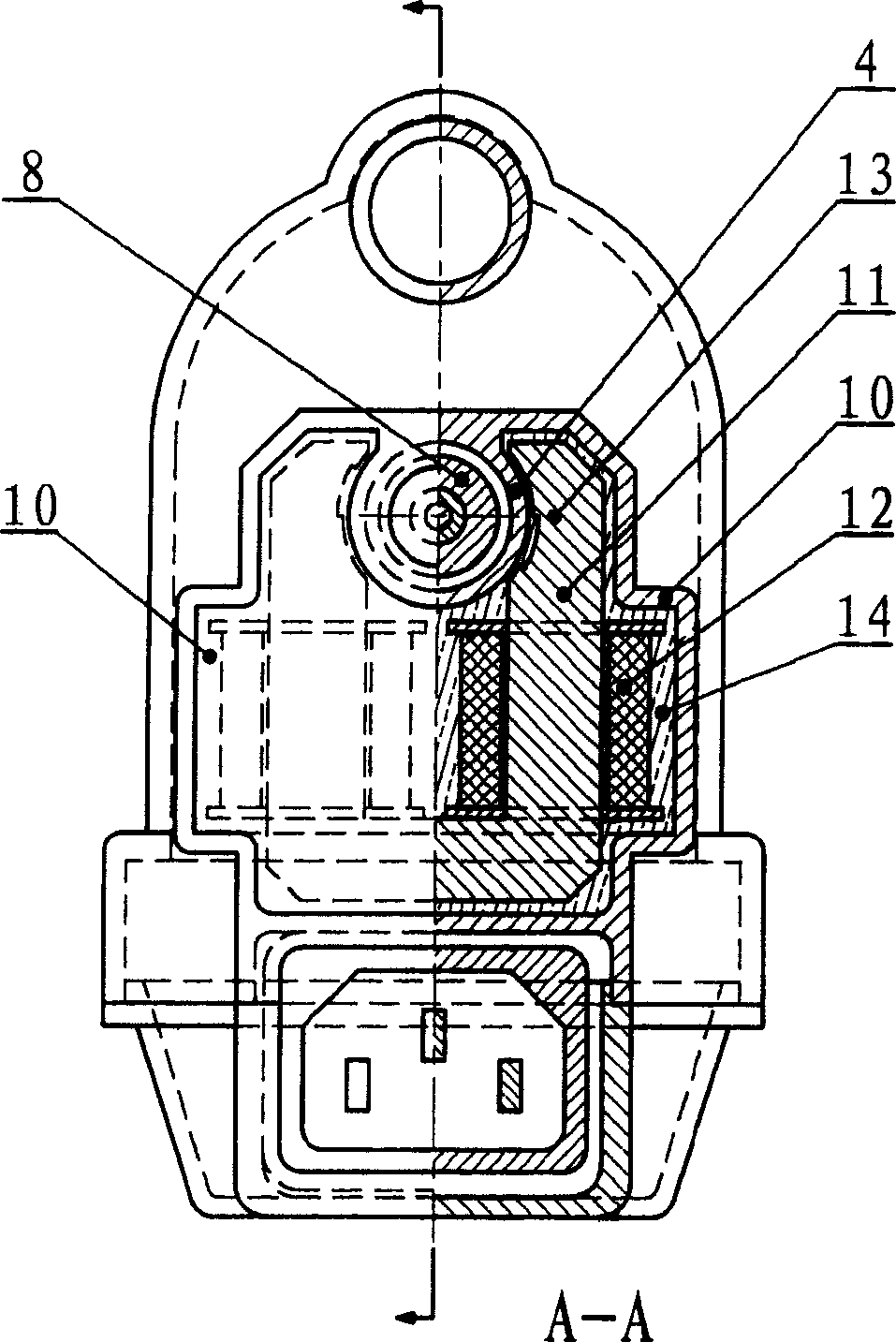

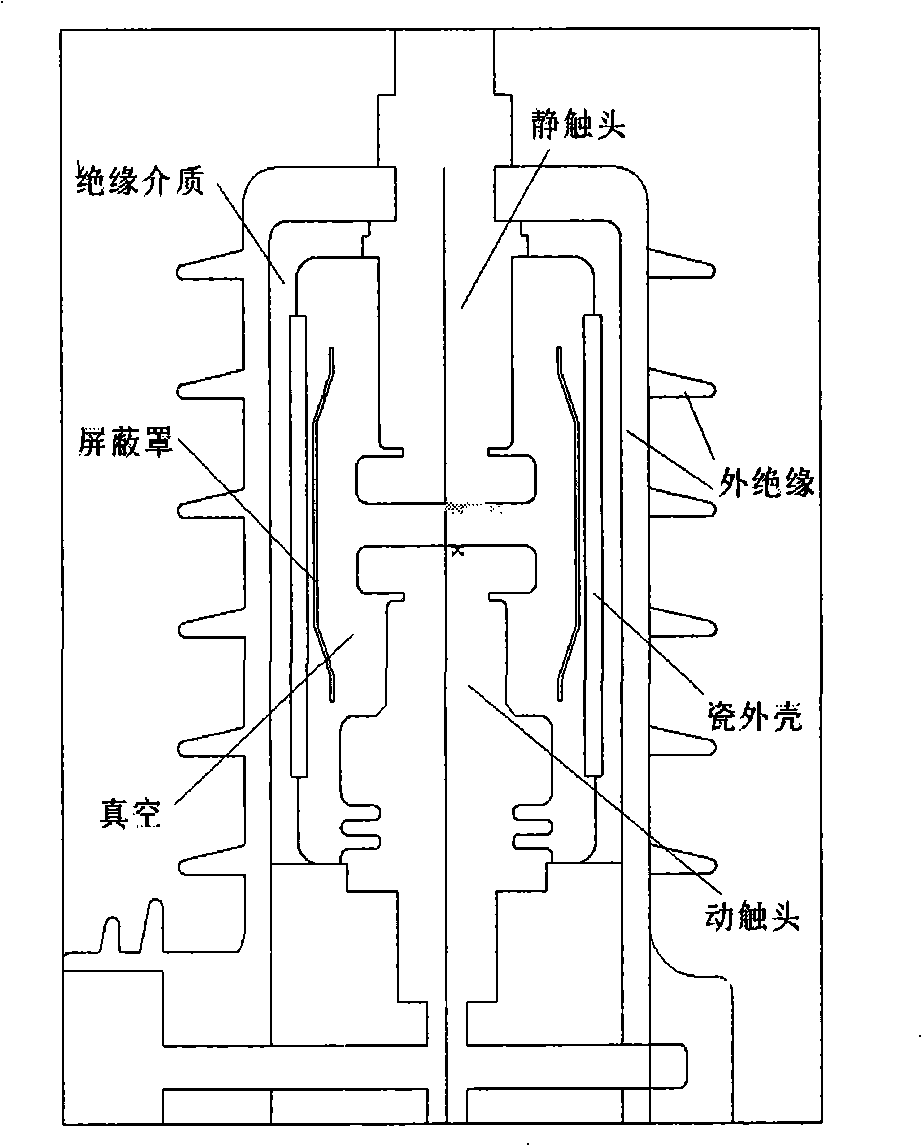

High voltage vacuum circuit breaker with high rated current value

InactiveCN1963972AIncrease the rated currentHigh thermal conductivityHigh-tension/heavy-dress switchesAir-break switchesHigh rateEngineering

The invention relates to a high-voltage vacuum breaker for high rated current. Wherein, the vacuum arc-extinguish chamber pole includes the ceramic sleeve for insulation to accommodate the chamber, a static conductive pole on one chamber end with an upper conductive ring and flange, a movable pose on another end with an lower conductive ring and conductive support with lower flange, two wire terminals on sleeve to connect former conductive rings; a first and second radiator near two flanges respectively; some insulation oil for heat dissipation between the sleeve and chamber and the support; and one or some holes on static pole to insert heat pipe.

Owner:XI AN JIAOTONG UNIV

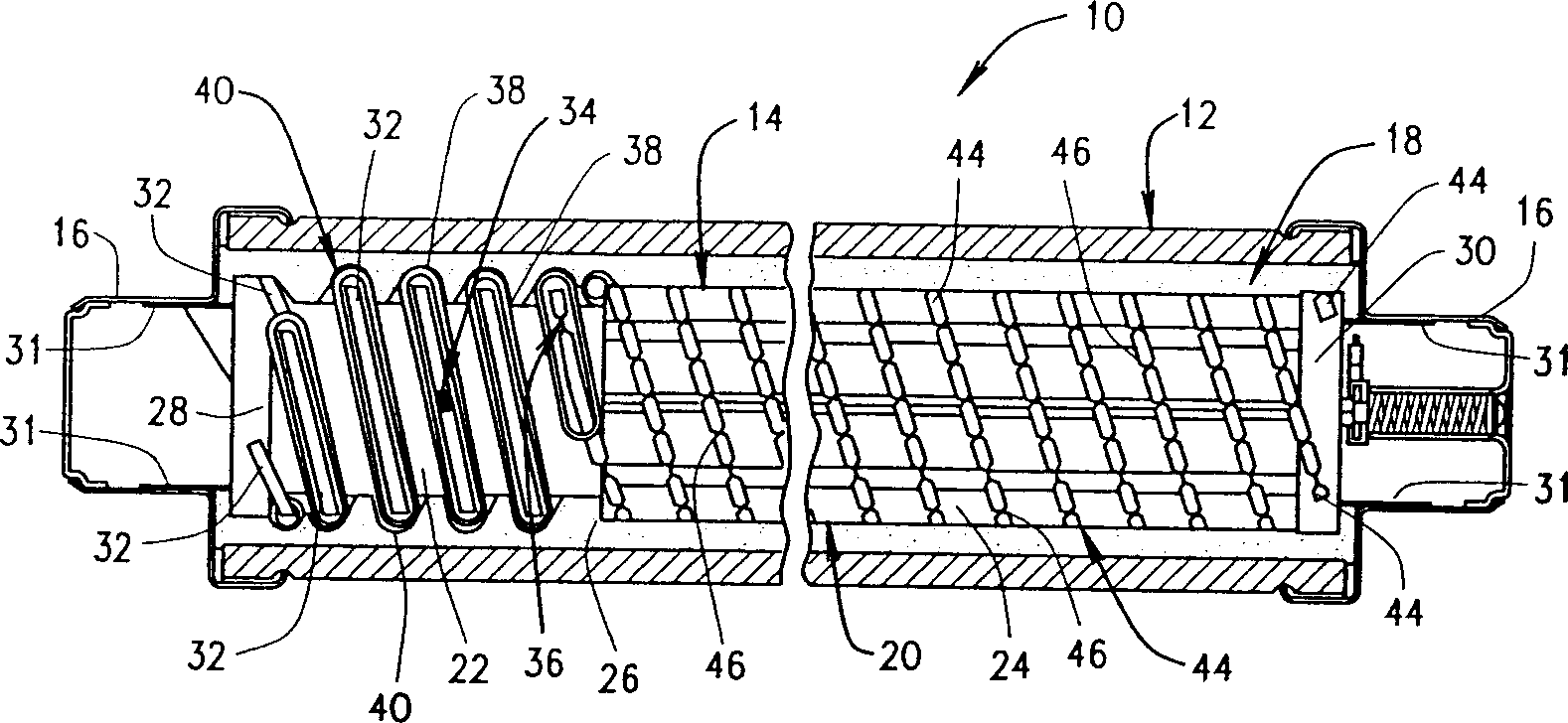

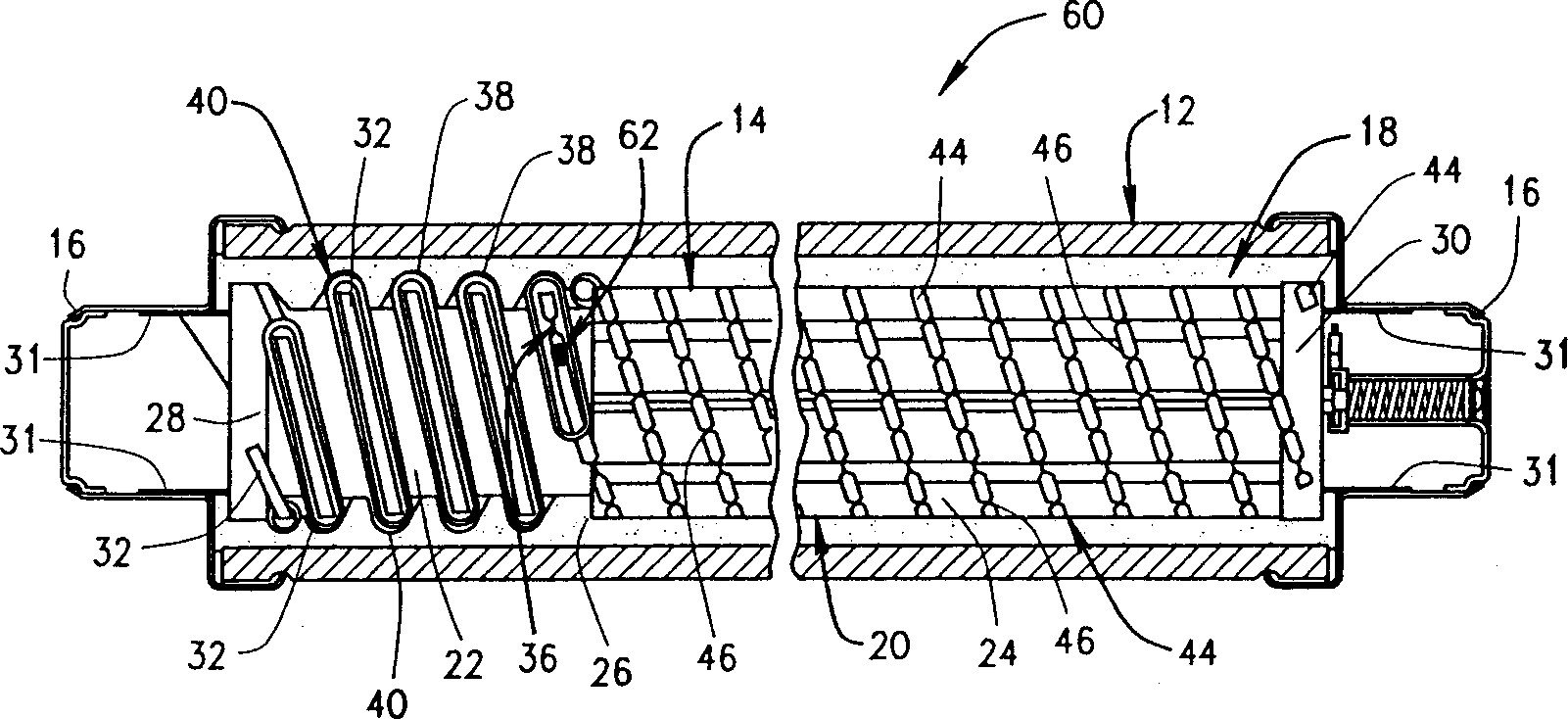

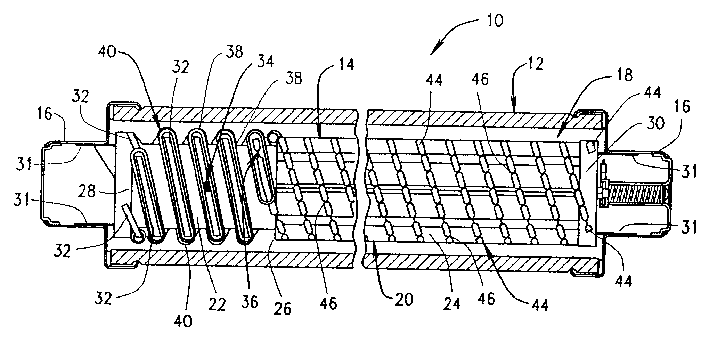

Whole-range high-voltage current-limiting fuse

InactiveCN1371114AEfficient dischargeAvoid damageEmergency protective devicesWeak currentCurrent limiting

The full-scale fuse element assembly includes an insulative bobbin having opposing first and second ends and a conductive connector coupled to the ends of the bobbin. A plurality of fuse elements extend around the insulating bobbin between the first connector and the second connector, and each fuse element includes a weak current interrupting fuse element portion extending from the first connector and a fuse element portion extending from the second connector. The part of the high current limiting fuse element that extends from the connector. An insulating bushing surrounds each part of the fuse element that interrupts the weak current, and each bushing includes an end portion adjacent to the high-current limiting fuse element. Each weak current interrupting fuse element portion includes a weak melting point adjacent the second end of the respective bushing.

Owner:COOPER UK LTD

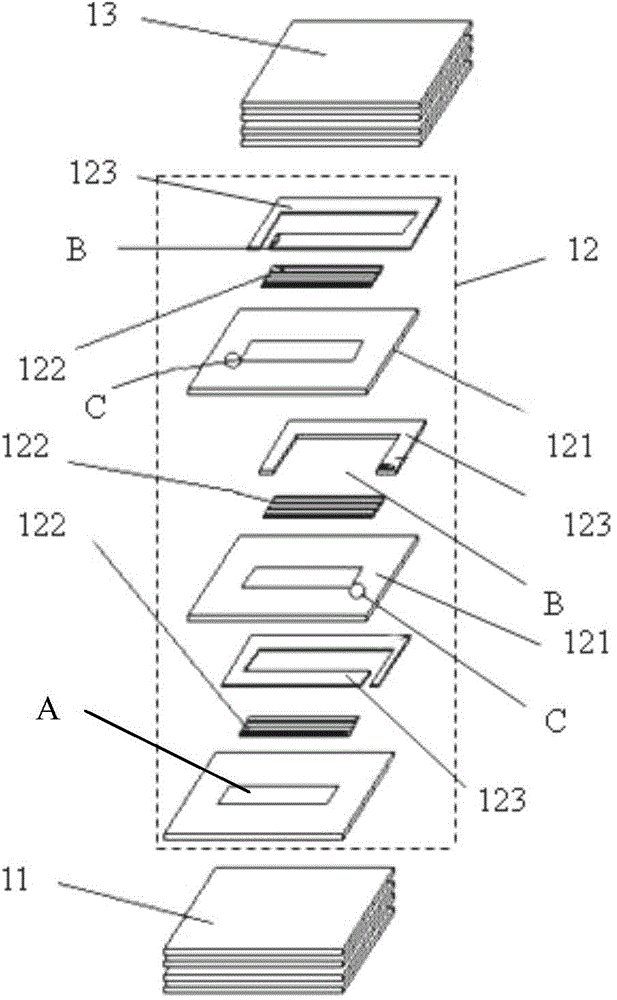

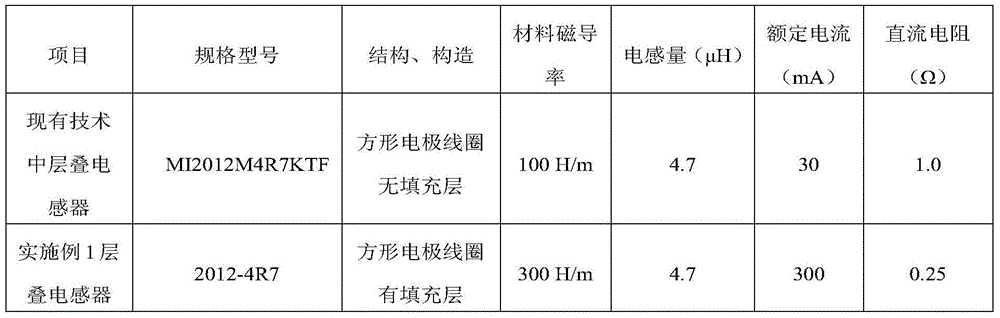

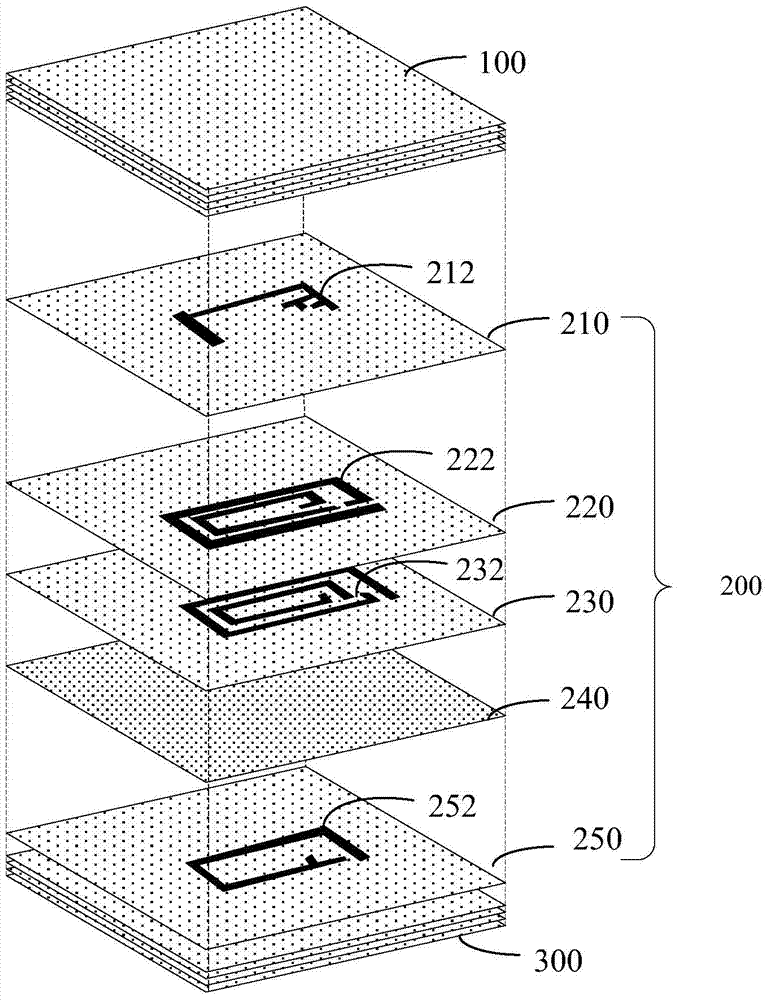

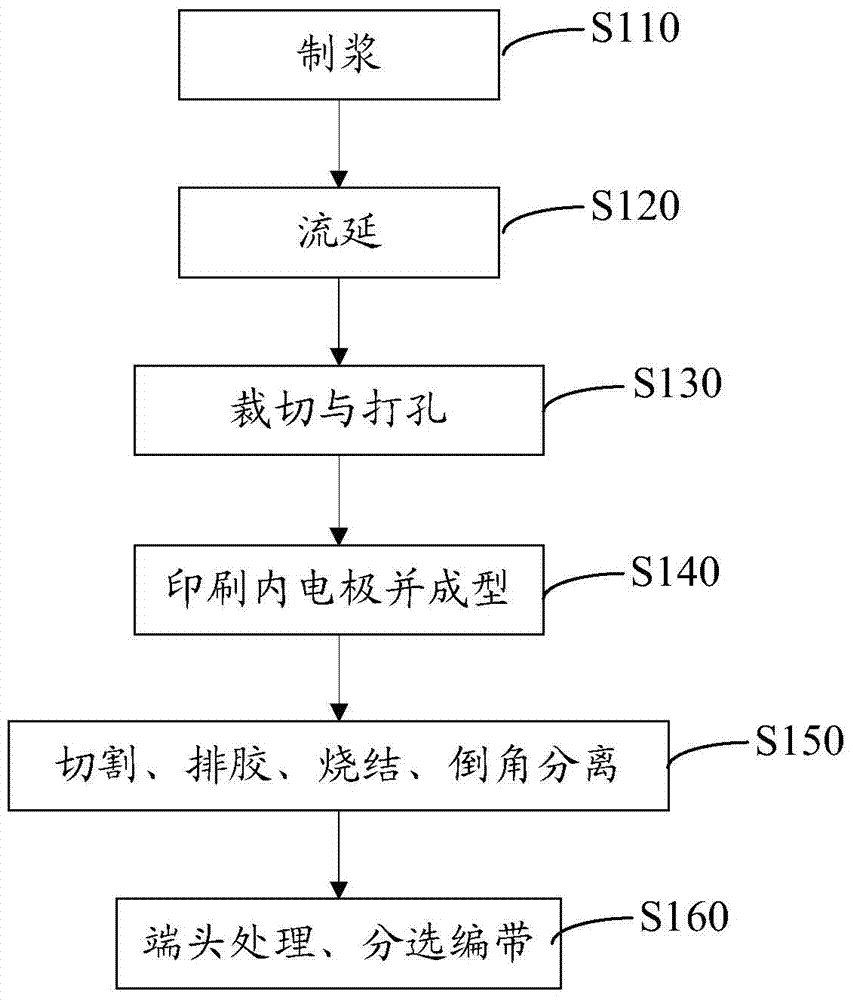

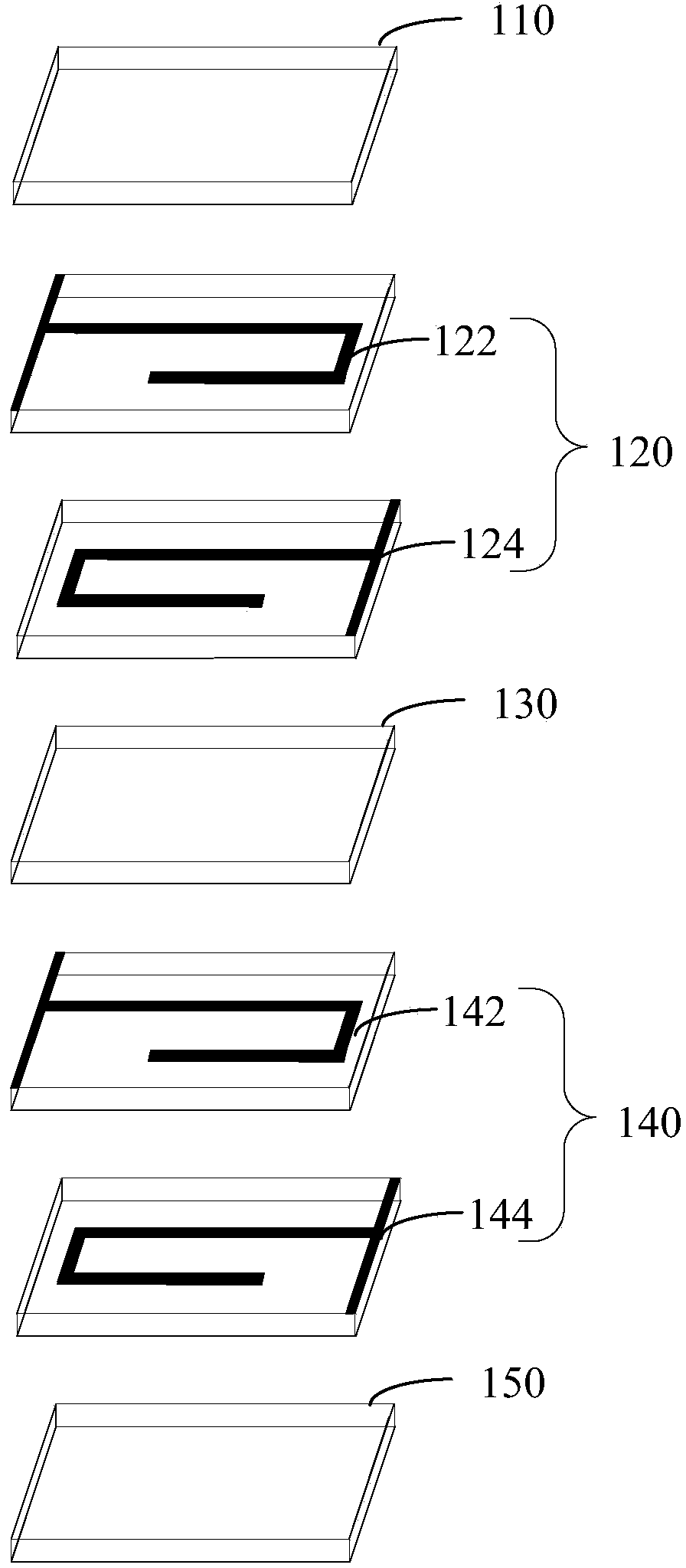

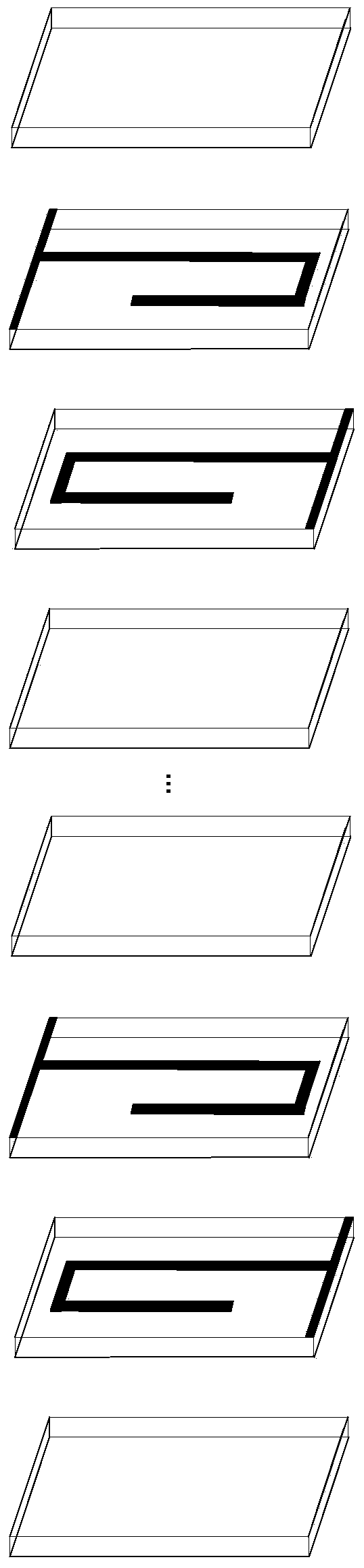

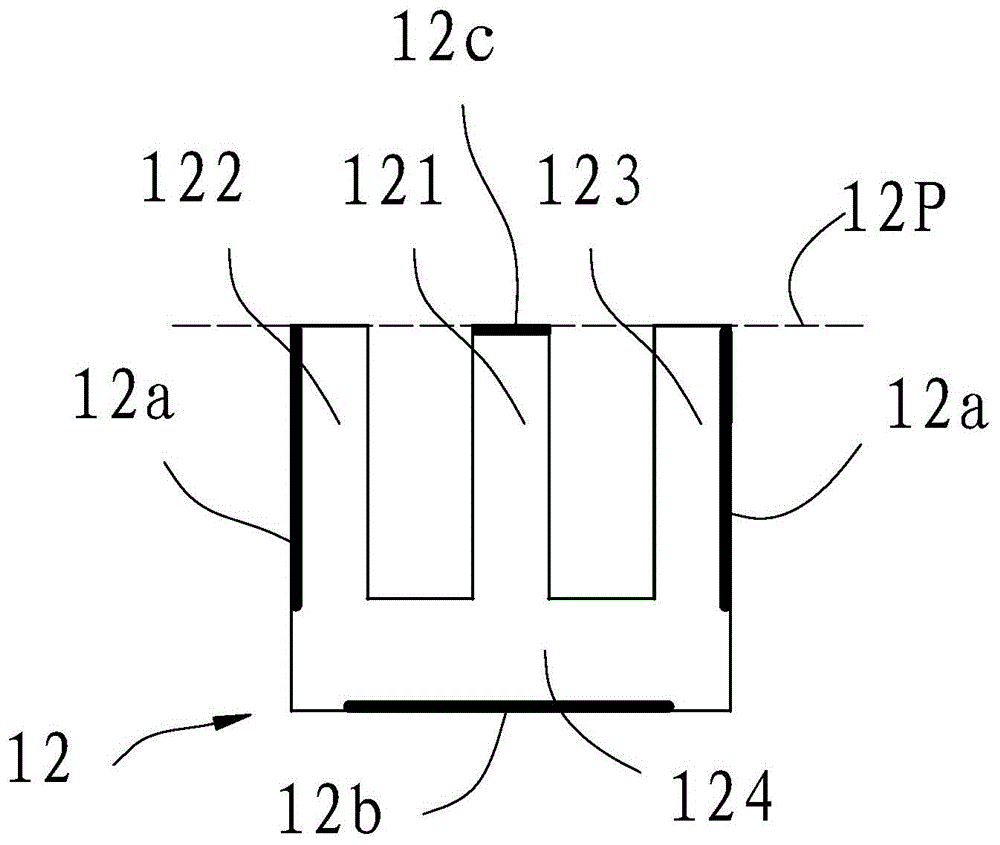

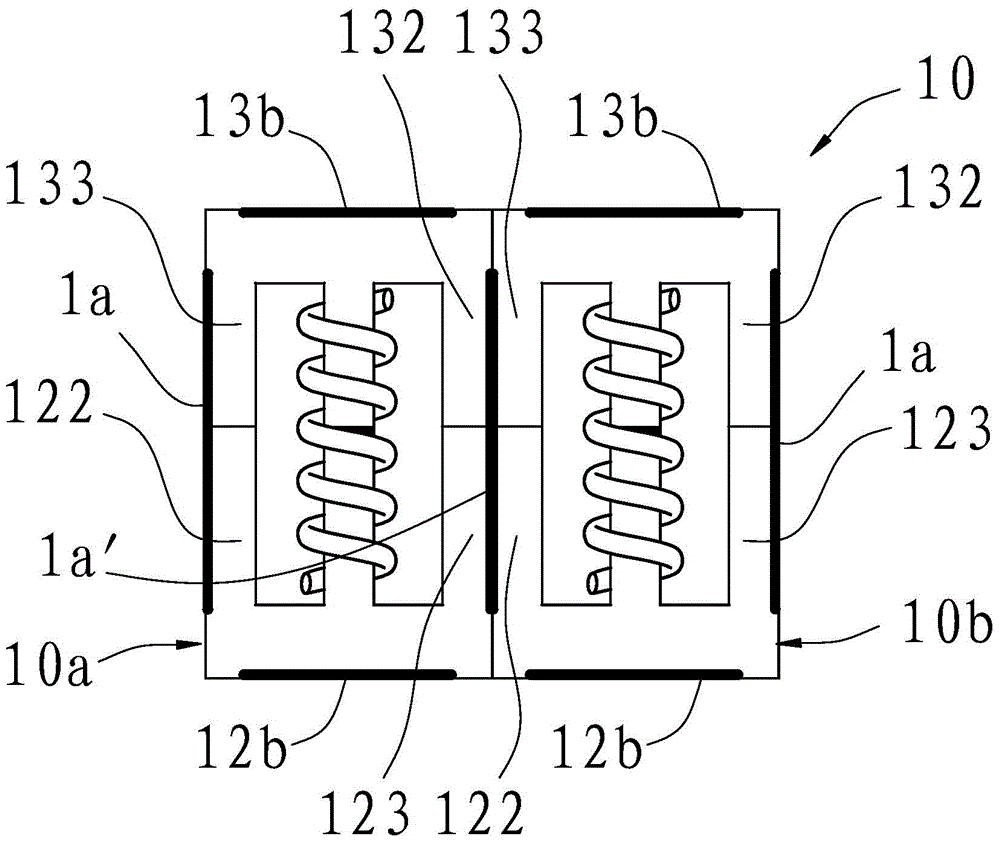

Cascading inductor based on metal magnetic slurry and preparation method thereof

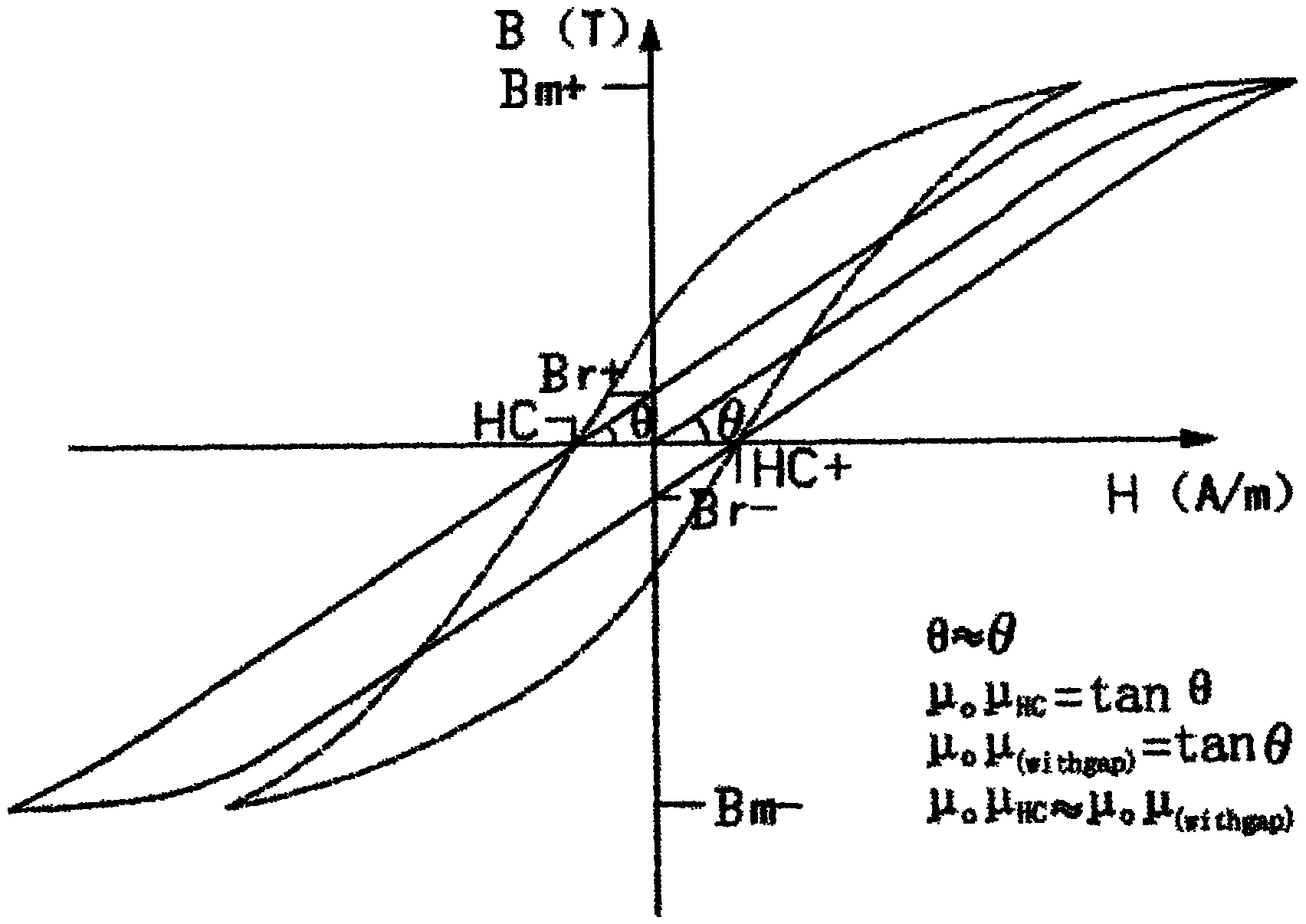

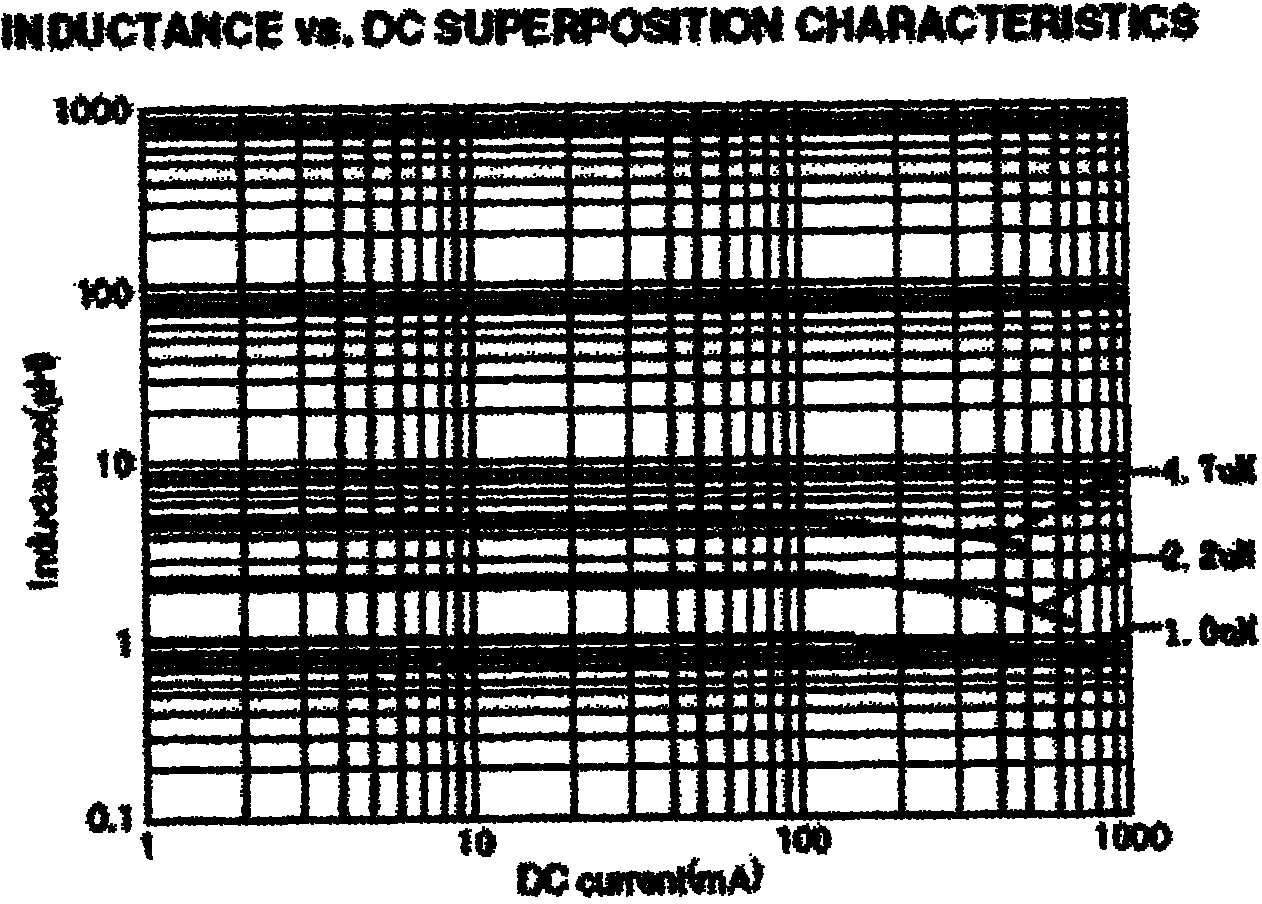

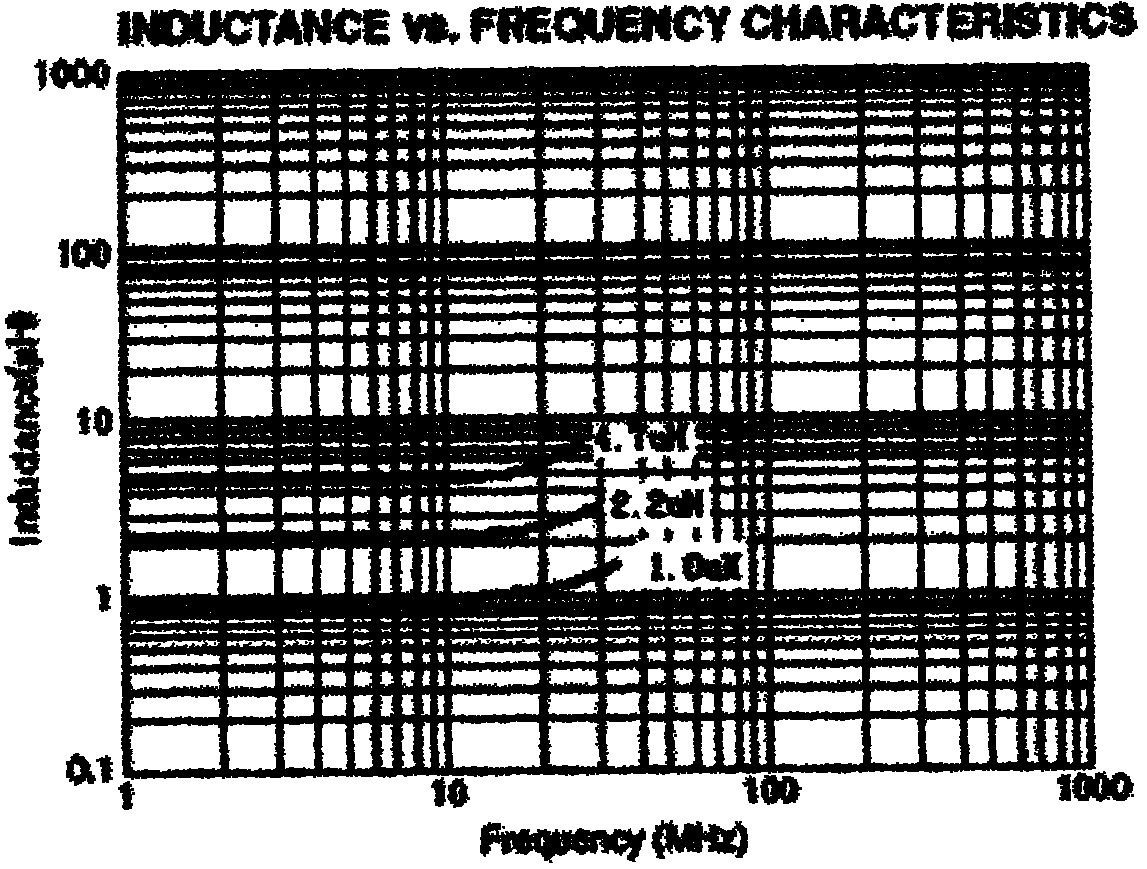

ActiveCN104465020AHigh saturation magnetizationIncrease the rated currentTransformers/inductances detailsInductances/transformers/magnets manufactureInter layerMetal alloy

The invention firstly aims to provide a cascading inductor based on metal magnetic slurry. The cascading inductor comprises a first base body, an interlayer and a second base body, wherein the first base body, the interlayer and the second base body are arranged from bottom to top. The interlayer comprises at least two single-layers arranged from bottom to top. Each single-layer comprises a dielectric layer, a packing layer and a coil electrode, wherein the dielectric layer is provided with a through hole in the vertical direction; the packing layer is arranged at the through hole, and the upper surface of the packing layer is not lower than the upper surface of the dielectric layer; the coil electrode is arranged on the upper surface of the dielectric layer and located around the packing layer; the packing layer comprises inorganic powder bodies composed of metal magnetic powder, lead-free glass powder, organic carriers and auxiliaries. The cascading inductor based on the metal magnetic slurry is simple in overall structure; since the packing layers are made of metal alloy materials with high saturation flux density, the saturation magnetization intensity of the whole cascading inductor is improved, and then the rated current is increased. The invention secondly aims to provide a preparation method of the cascading inductor based on the metal magnetic slurry. By means of the preparation method, the process steps are simple, the cost is low, and the cascading inductor is quite suitable for large-scale batch production.

Owner:SHENZHEN GUDIAN ELECTRONICS

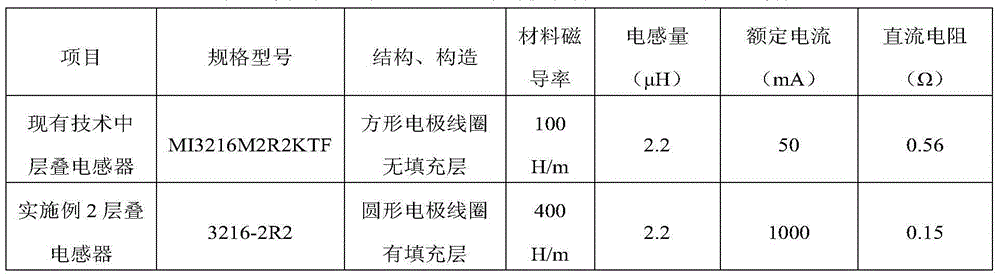

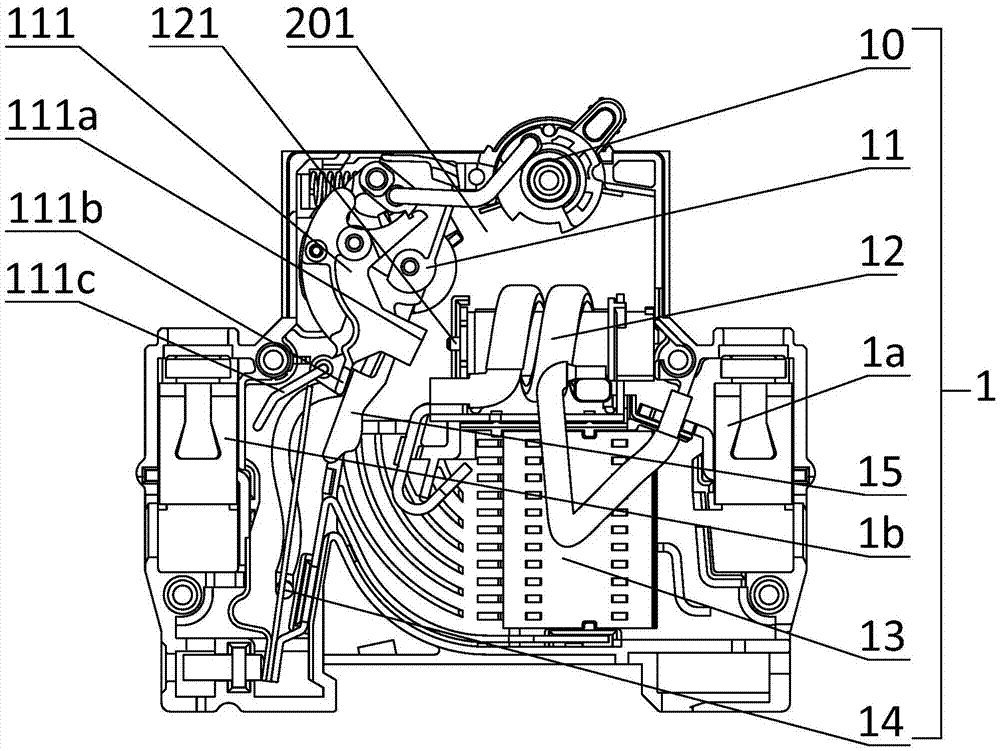

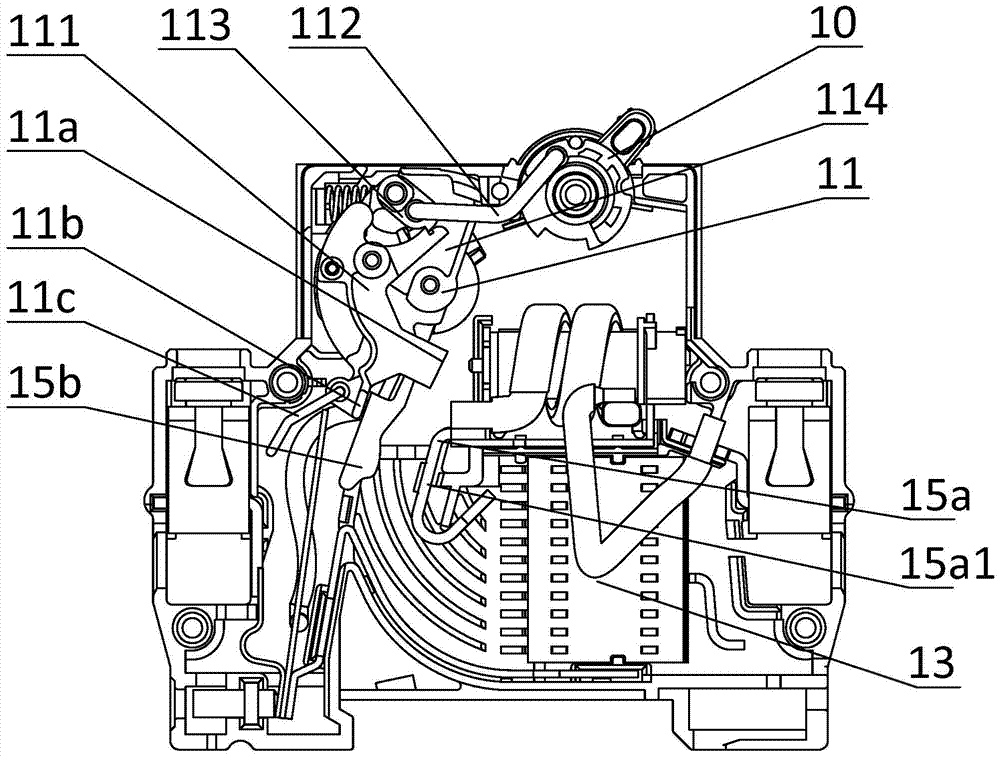

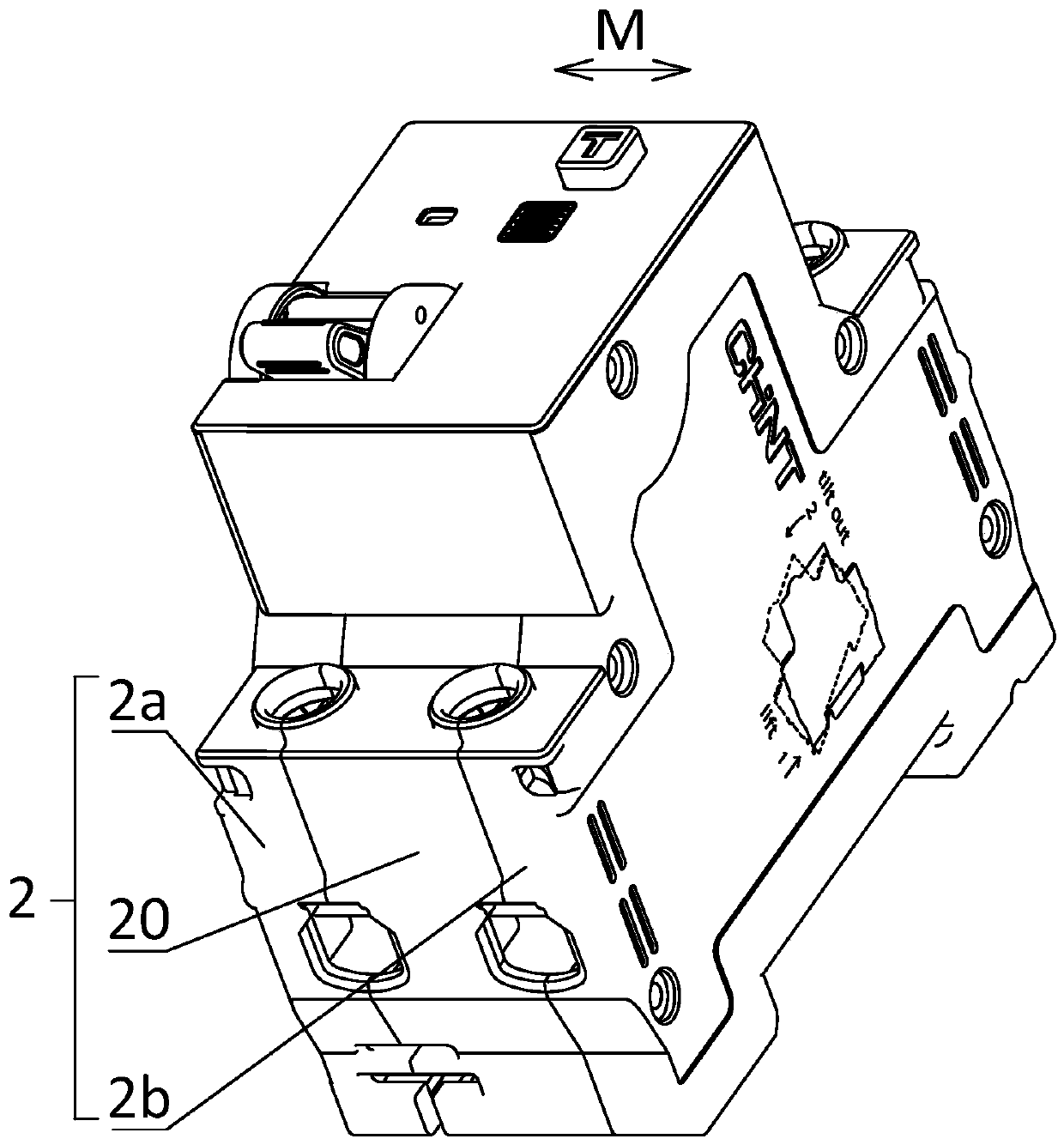

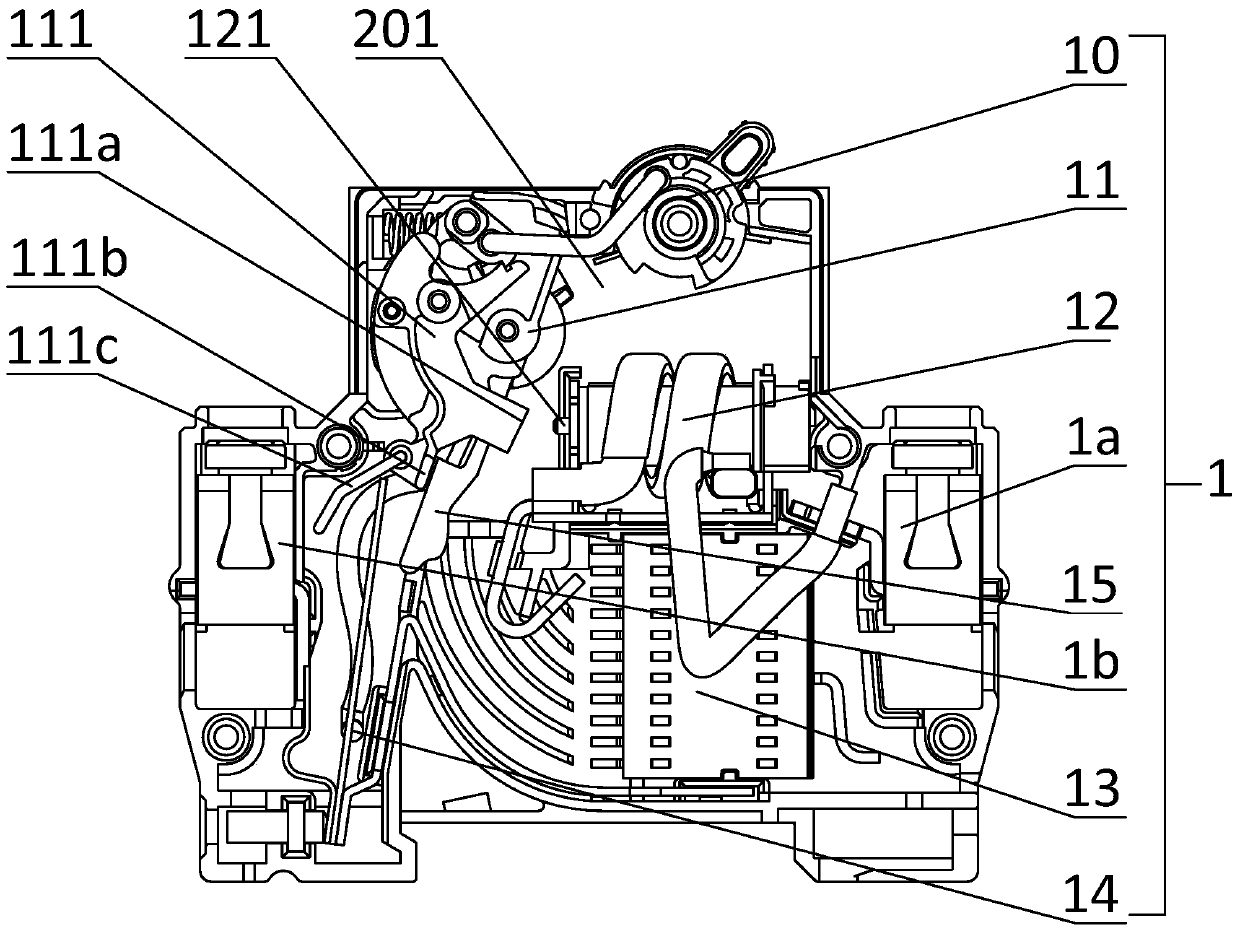

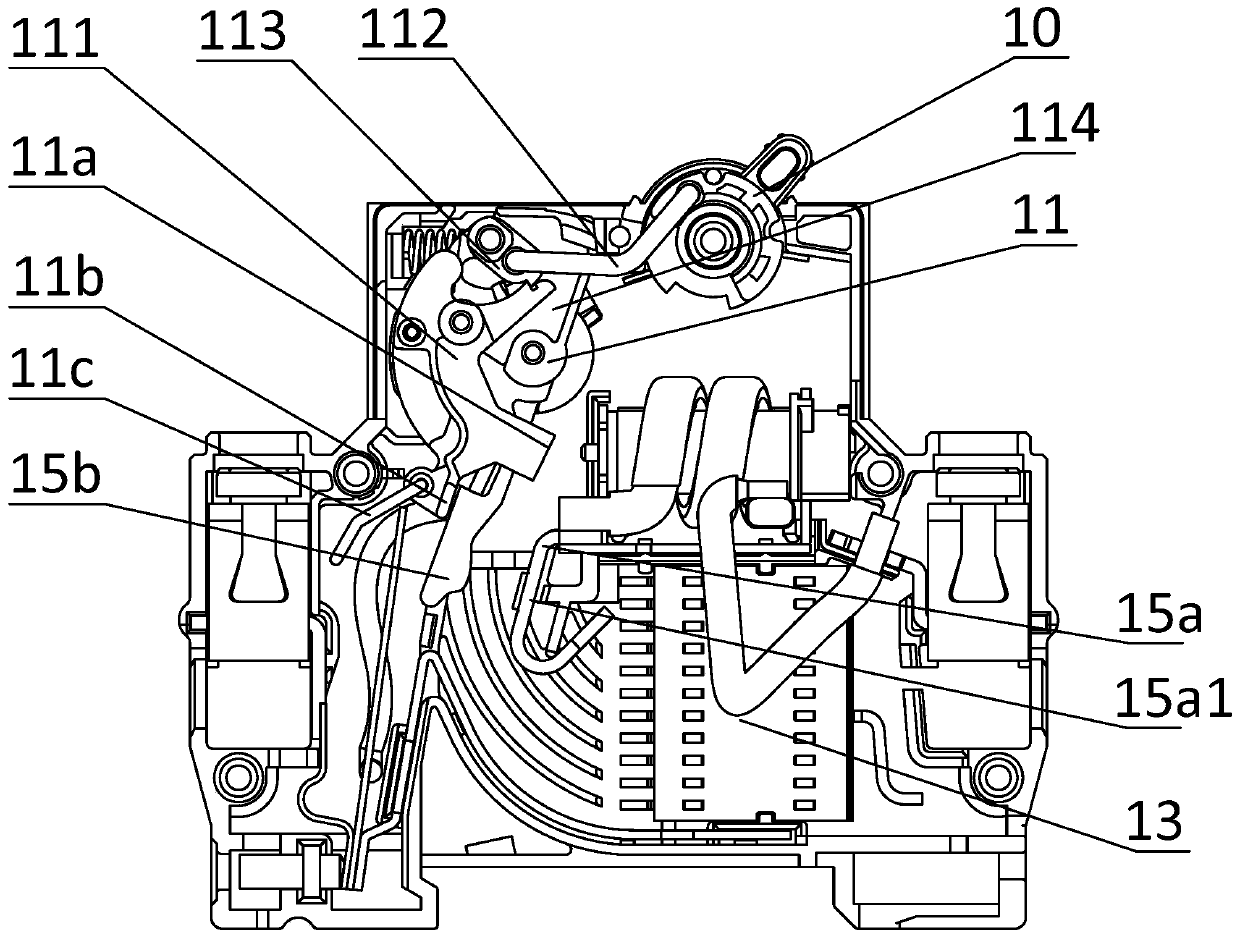

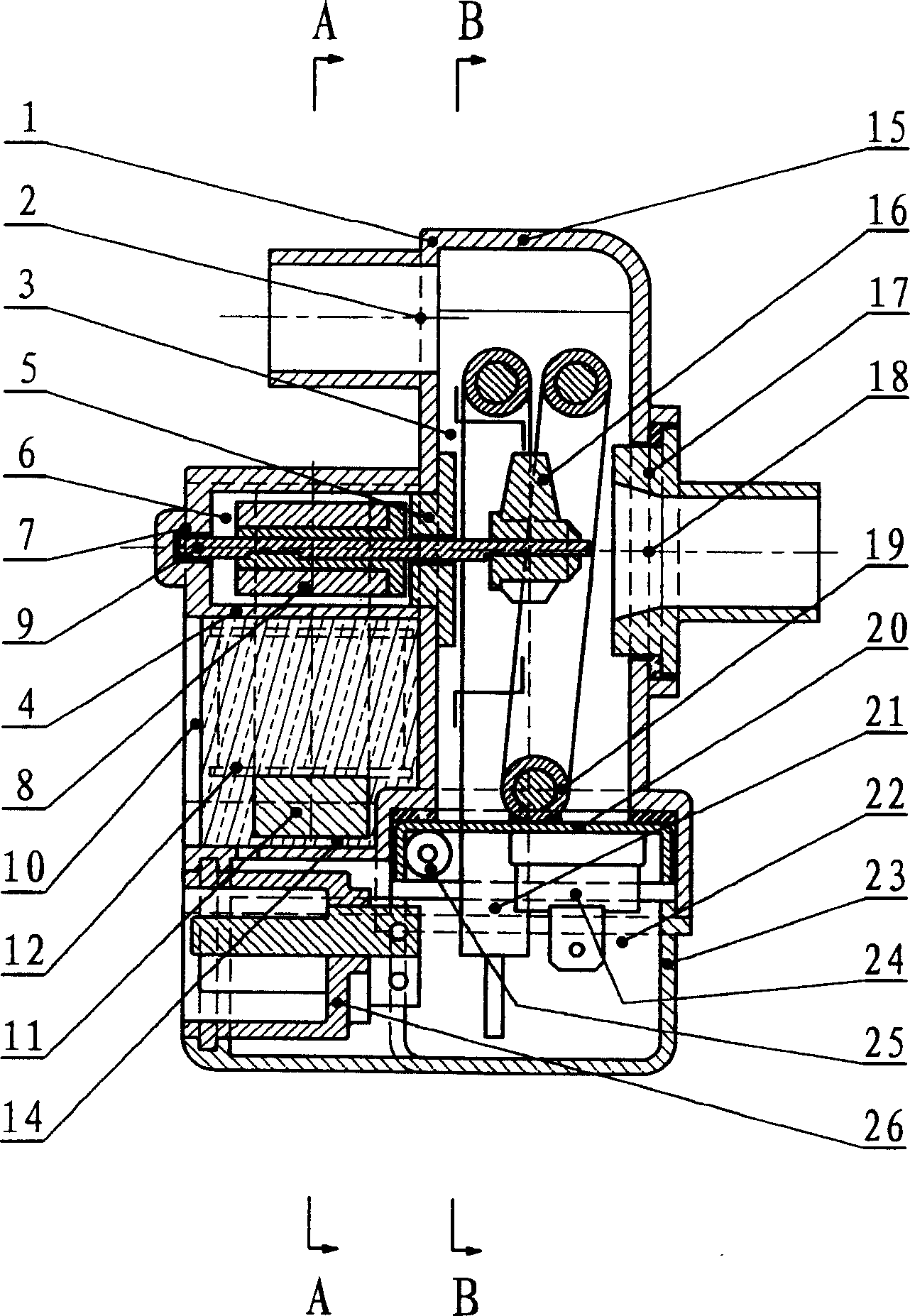

Electronic type leakage circuit breaker

ActiveCN107146745AAchieve full utilizationReduce product temperature riseProtective switch operating/release mechanismsCarrying capacityPower flow

The invention provides an electronic type leakage circuit breaker, which comprises a shell. A partition plate arranged in the shell divides the shell into two layers of cavities. The two layers of cavities are composed of a first cavity and a second cavity. The first cavity is used for placing an L-pole circuit breaker module. The second cavity is used for placing an N-pole circuit breaker module and a leakage protection module of the electronic type leakage circuit breaker. Therefore, the internal space of a product is fully utilized. Meanwhile, through improving the rated current, the high temperature rise and other unqualified phenomena can be avoided. Therefore, the safe current-carrying capacity of the electronic type leakage circuit breaker is ensured, and the rated current of the electronic type leakage circuit breaker reaches 63A.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD +1

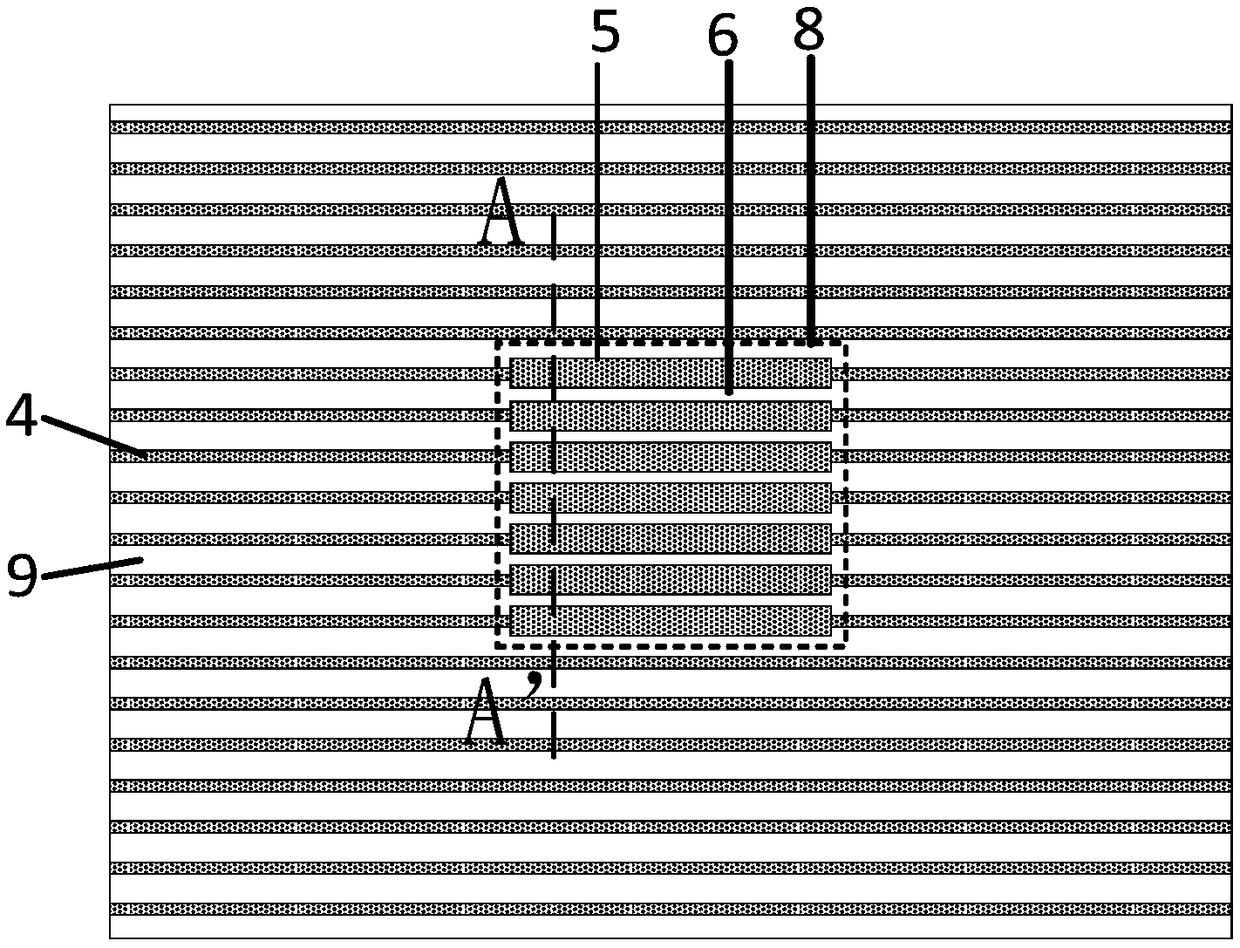

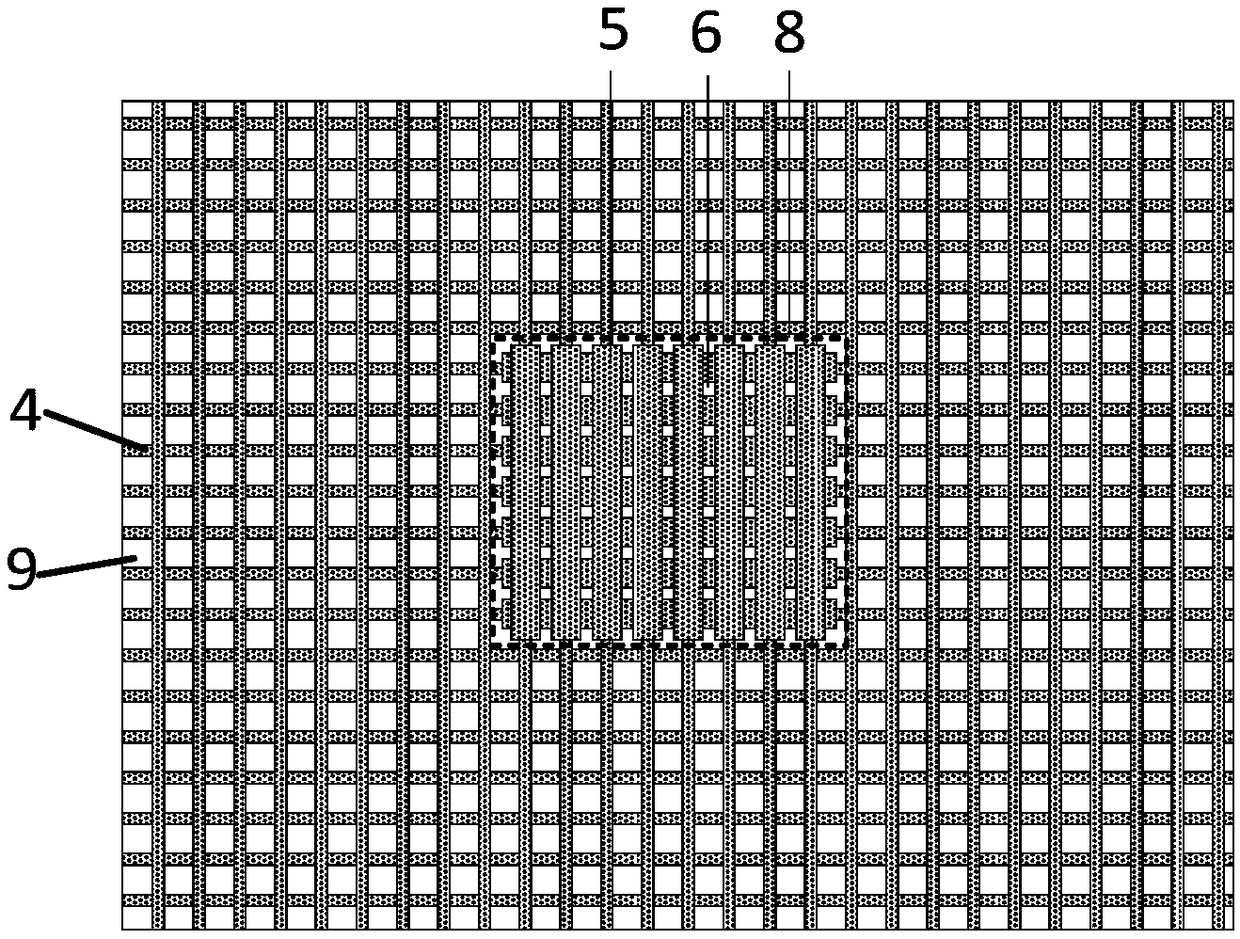

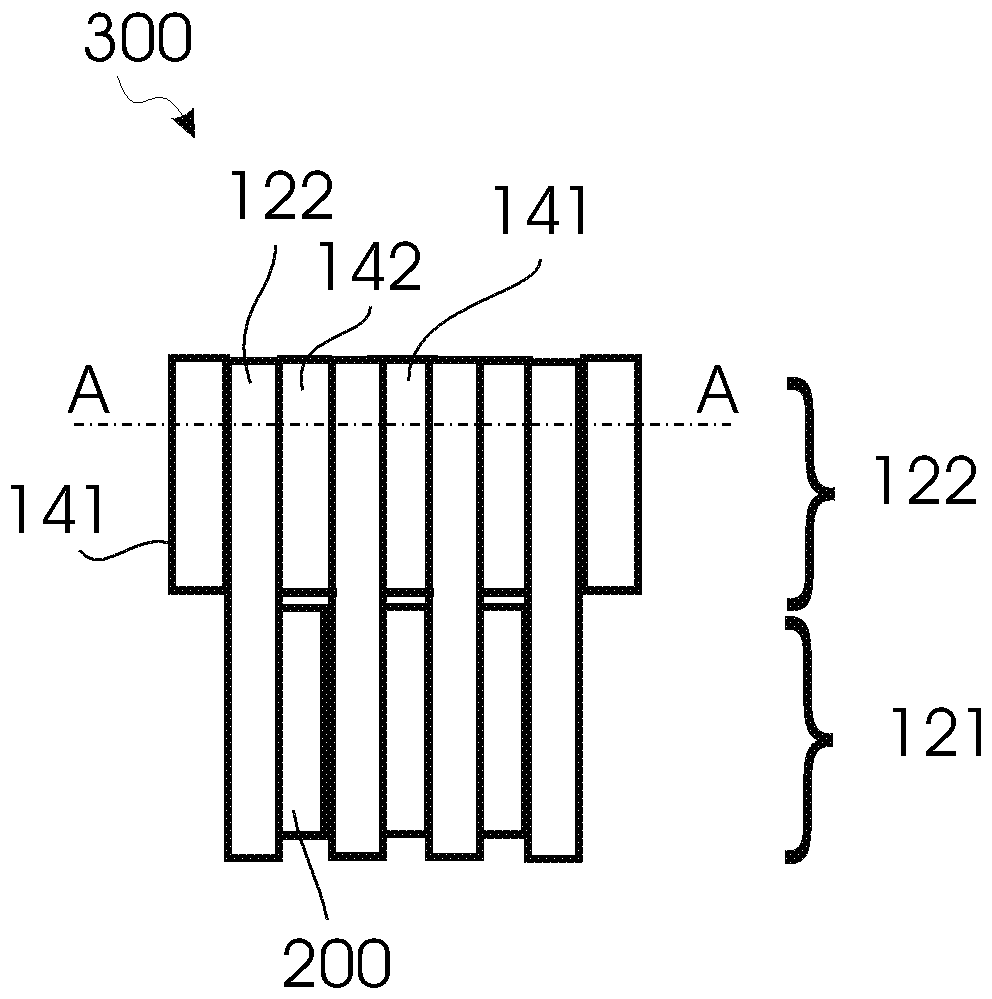

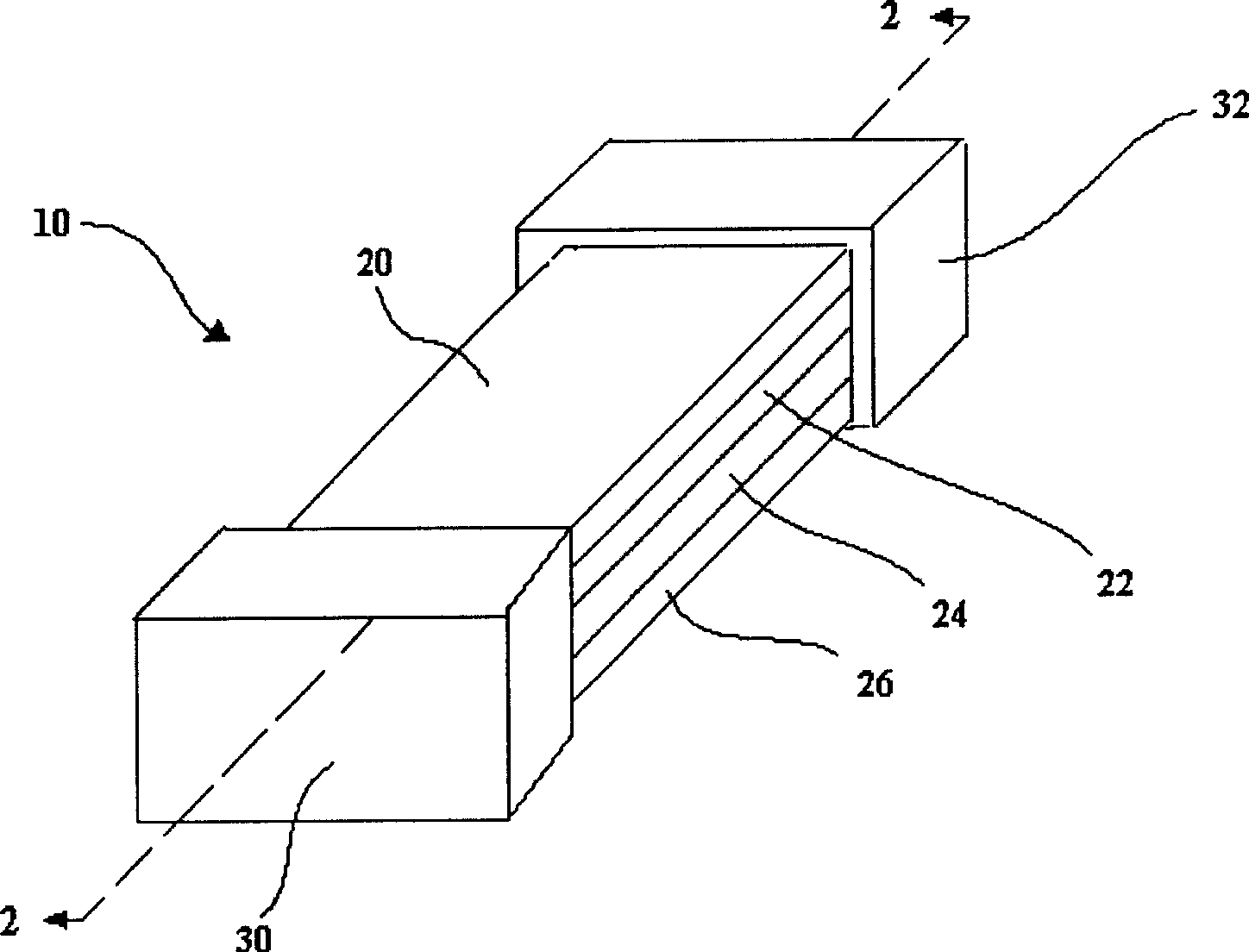

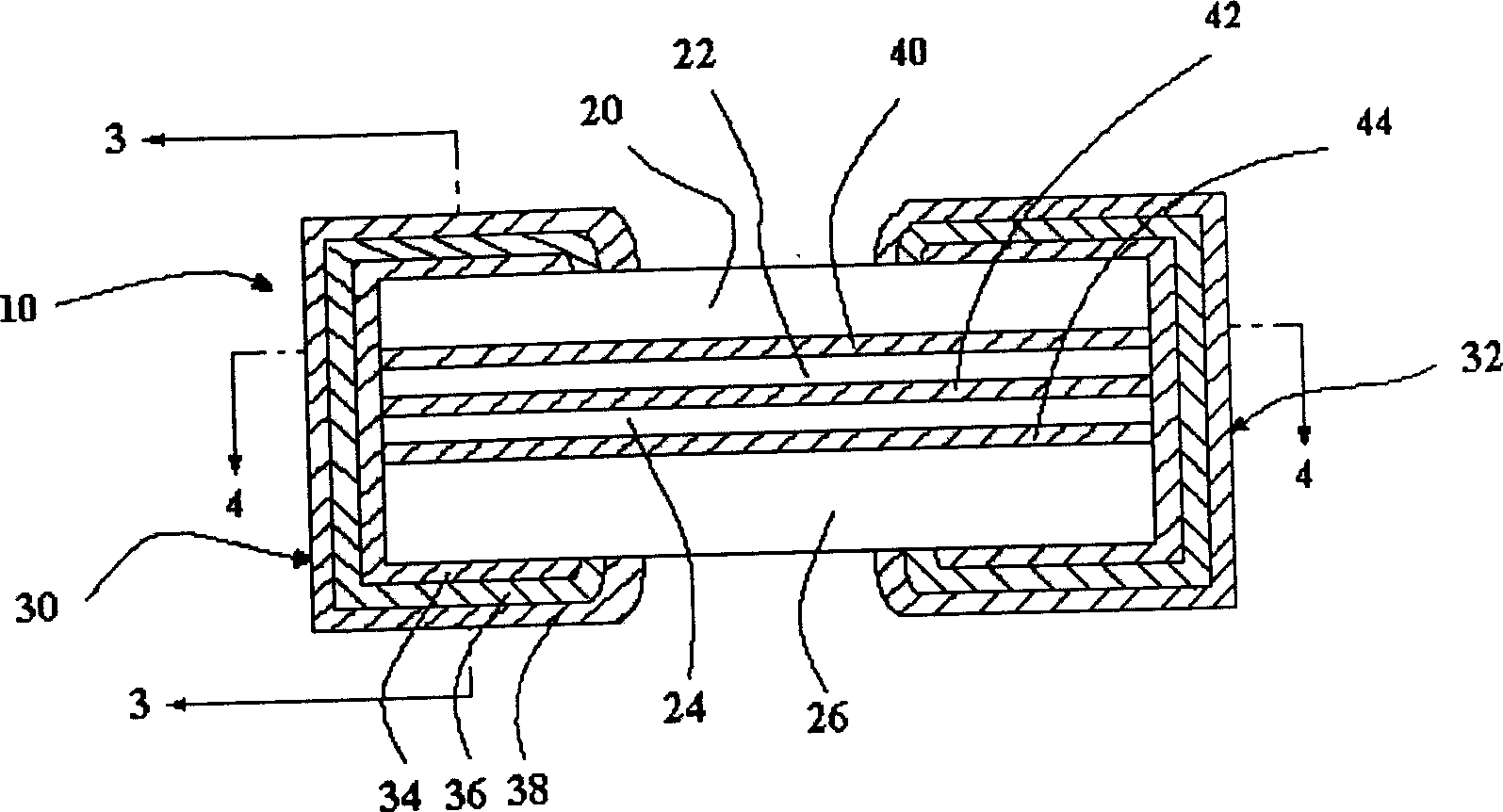

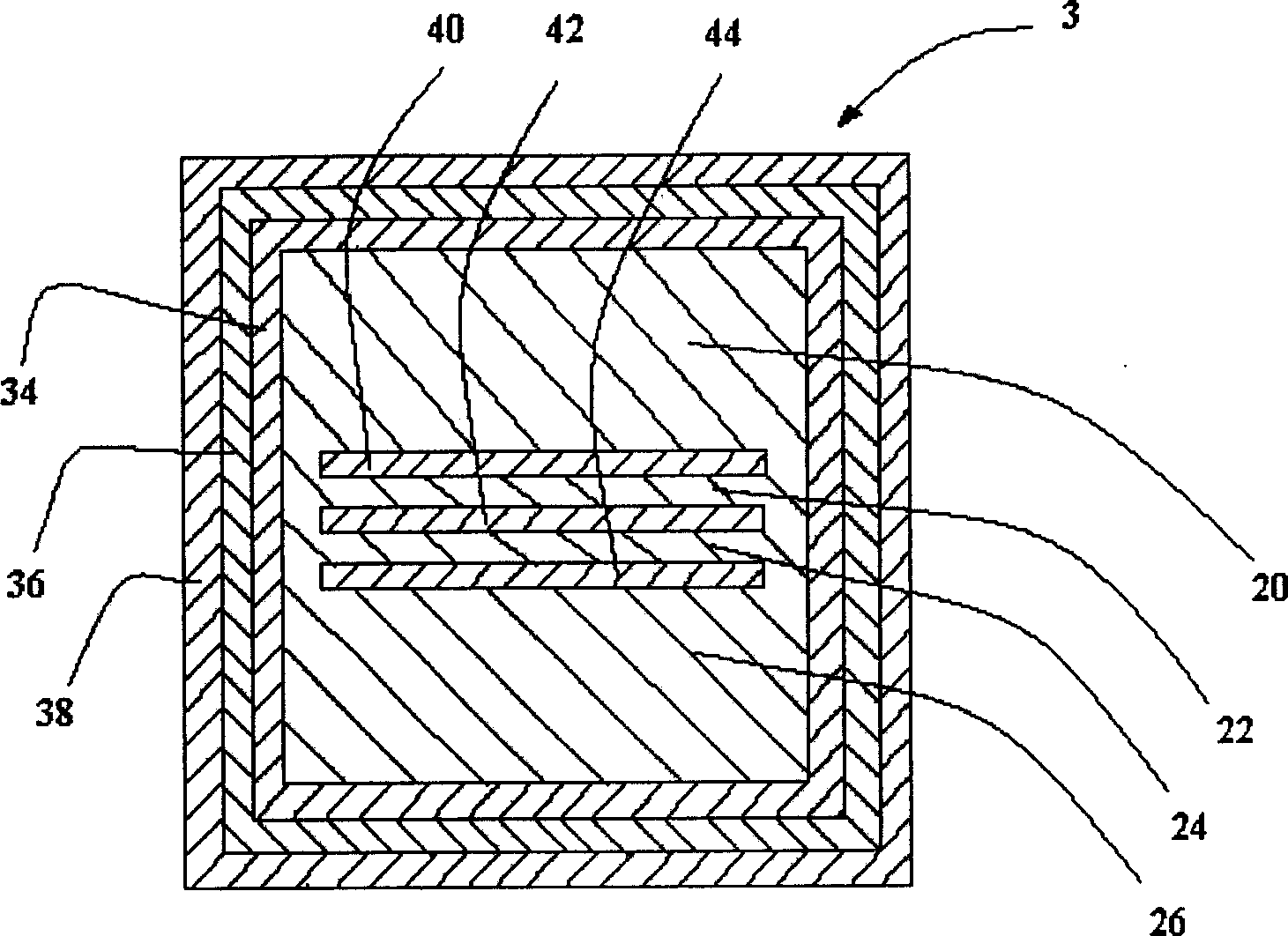

Multilayer chip inductor and manufacturing method thereof

ActiveCN103680893AIncrease the rated currentPlay the role of parallel shuntTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInter layerInductor

Provided is a multilayer chip inductor. The multilayer chip inductor comprises a first cover body, a middle layer and a second cover body, wherein the first cover body, the middle layer and the second cover body are stacked in sequence, the middle layer comprises a lead layer which is stacked in a parallel mode, and more than two dielectric layers, electrode coils are printed on the dielectric layers, wires of the electrode coils on every two adjacent dielectric layers are distributed in a parallel and parallel connection mode, and the lead layer is close to the first cover body or the second cover body. The rated current of the multilayer chip inductor can be greatly increased, and the multilayer chip inductor can be widely applied to electronic devices such as computers and communication machines.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

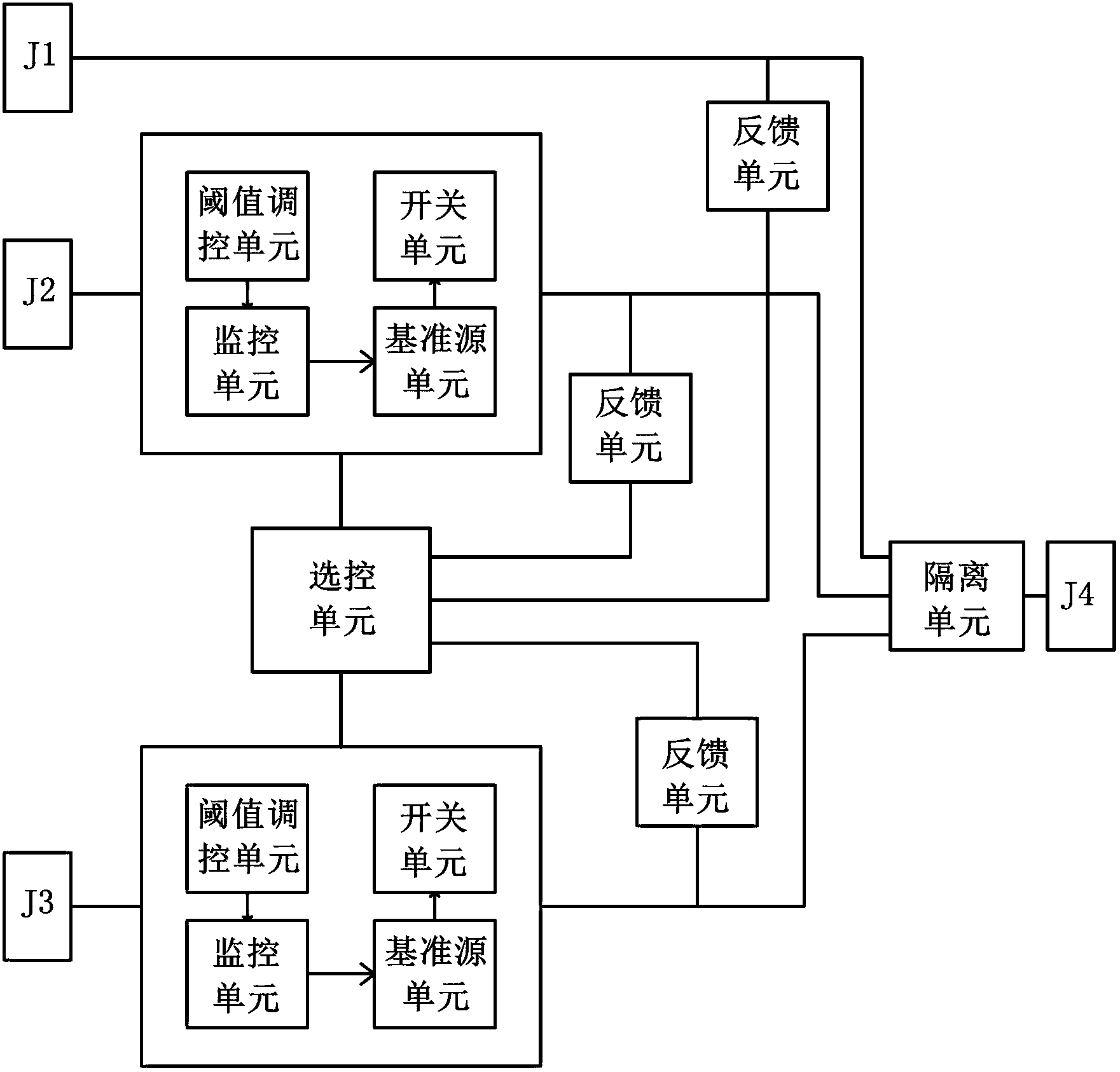

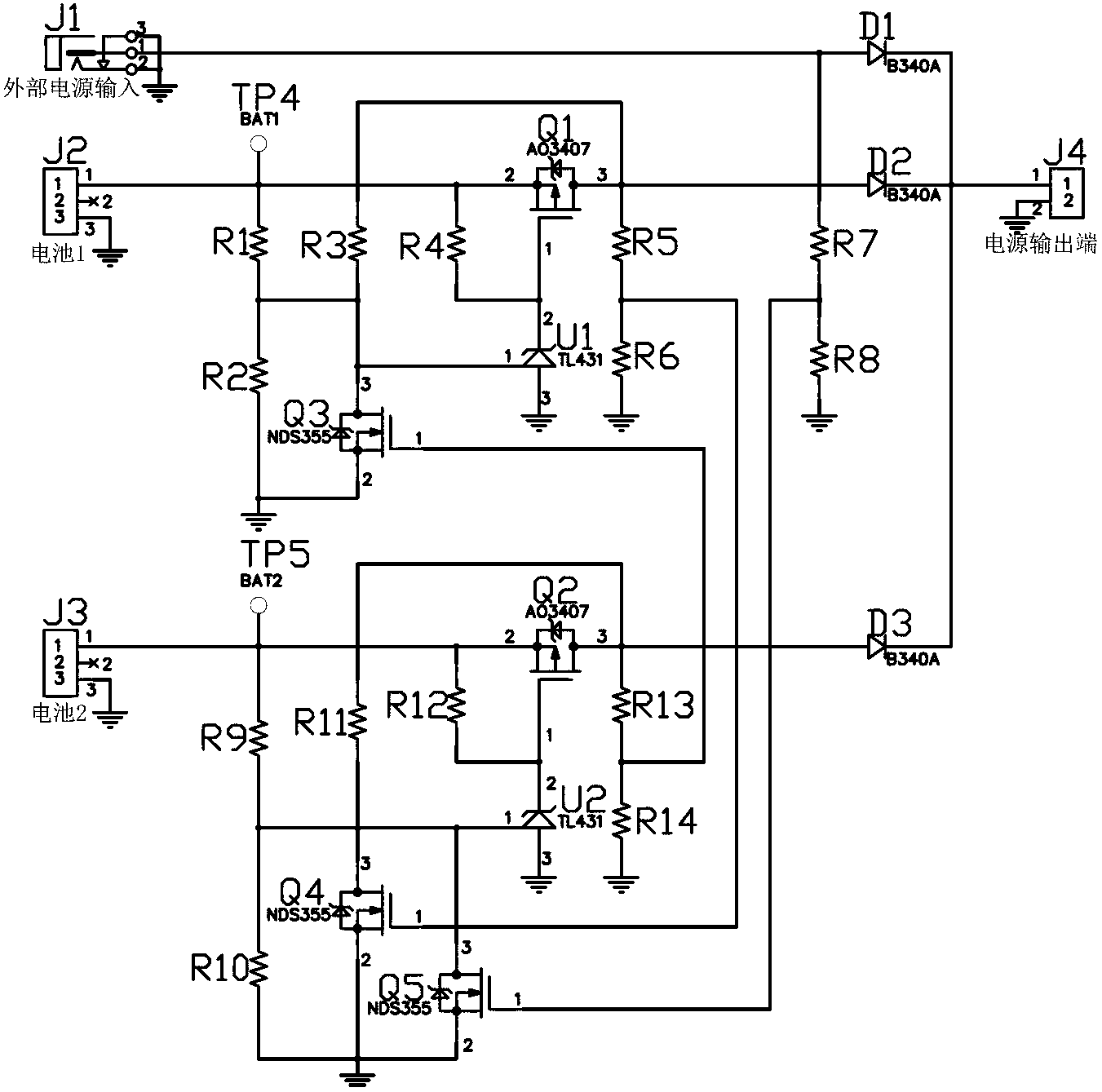

Analog double-cell management method and circuit thereof

ActiveCN103023110AShort response timeIncrease the rated currentElectric powerEnd cell switching arrangementsPower flowElectrical battery

The invention provides an analog double-cell management method and a corresponding management circuit. The management circuit comprises a plurality of power supply modules, an output end, a selective control unit, a plurality of feedback units and an isolation unit, wherein each power supply module comprises an input end, an output end and a control end, and the input end is connected with cells; and the power supply modules, the selective control unit, the plurality of the feedback units and the isolation unit are achieved through analog circuits. The analog double-cell management method and the circuit thereof have the advantages that selection management of power supply of two cells in double-cell power supply equipment is achieved through the analog circuits, compared with the existing double-cell management technology achieved by digital circuits, response time is shorter, the rated current is larger, and the application of double-cell power supply equipment which has high requirement for response time and / or control current becomes possible.

Owner:CHENGDU JIUZHOU ELECTRONIC INFORMATION SYSTEM CO LTD

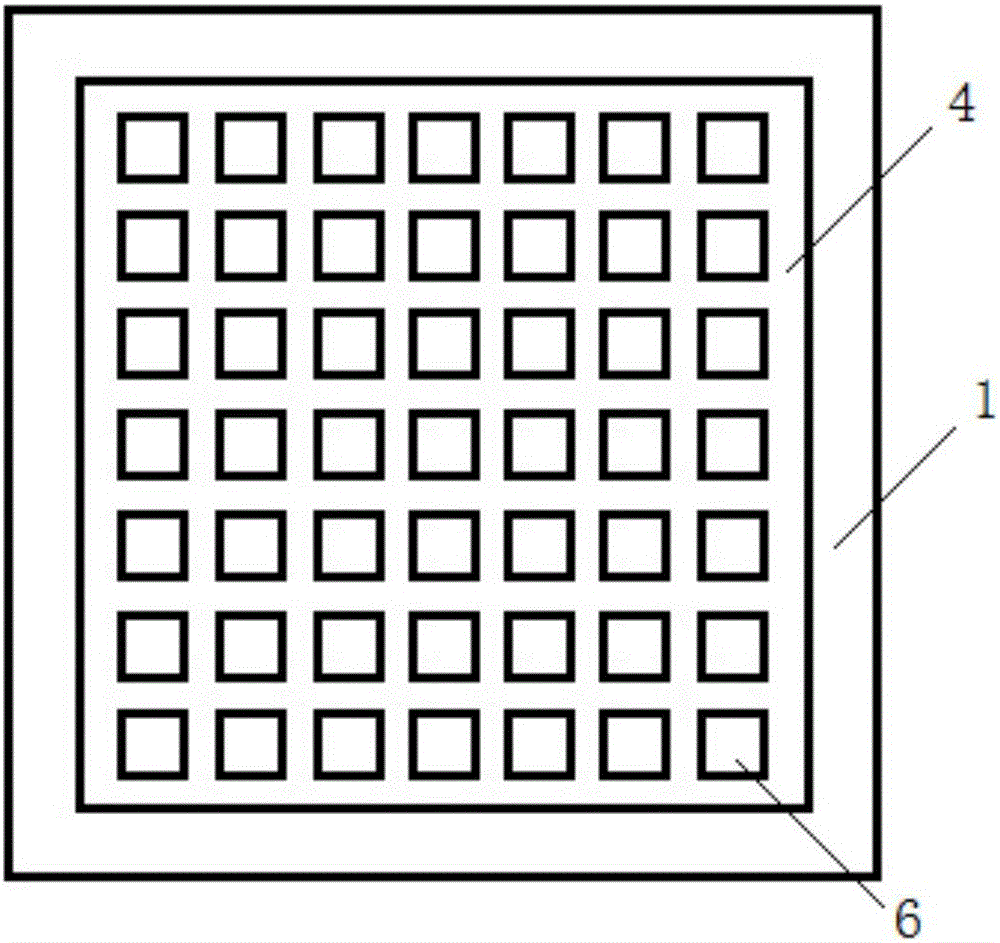

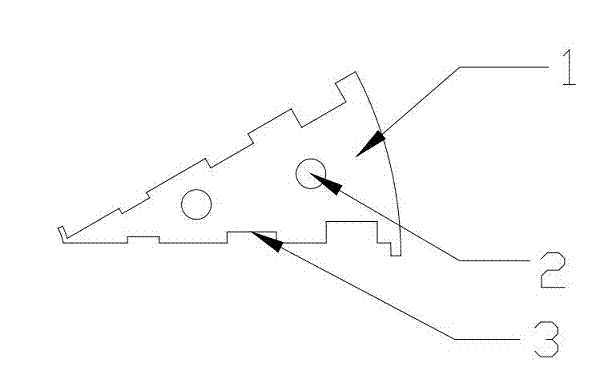

Chip structure for effectively increasing PN junction area and manufacturing method thereof

InactiveCN105870078AIncrease the areaIncrease the rated currentSemiconductor/solid-state device detailsSolid-state devicesSemiconductor technologySemiconductor

The invention relates to a chip structure for effectively increasing the PN junction area and a manufacturing method thereof, and belongs to the technical field of semiconductors. The chip structure comprises a chip body, wherein the chip body comprises a substrate layer and a heavily doped layer which is reverse to the substrate layer in current conduction type and is formed by doping on one side or two sides of the substrate layer; a PN junction is formed on an intersection between the heavily-doped layer and the substrate layer; a naked part of the PN junction is covered with a passive layer; the upper surface and the lower surface of the chip body are covered with metal layers; the PN junction is formed by connecting a plurality of U-shaped curved surface junctions end to end; the middle parts of the U-shaped curved surface PN junctions are planar junctions. According to the chip structure, a plurality of U-shaped PN curved surface junctions are designed instead of an original planar PN junction, so that the area of the PN junction is increased effectively on the premise of not increasing the size of an original chip body, thereby fulfilling the aim of increasing the rated current of the chip on the basis of not increasing the manufacturing cost.

Owner:ZHEJIANG MINGDE MICROELECTRONICS CO LTD

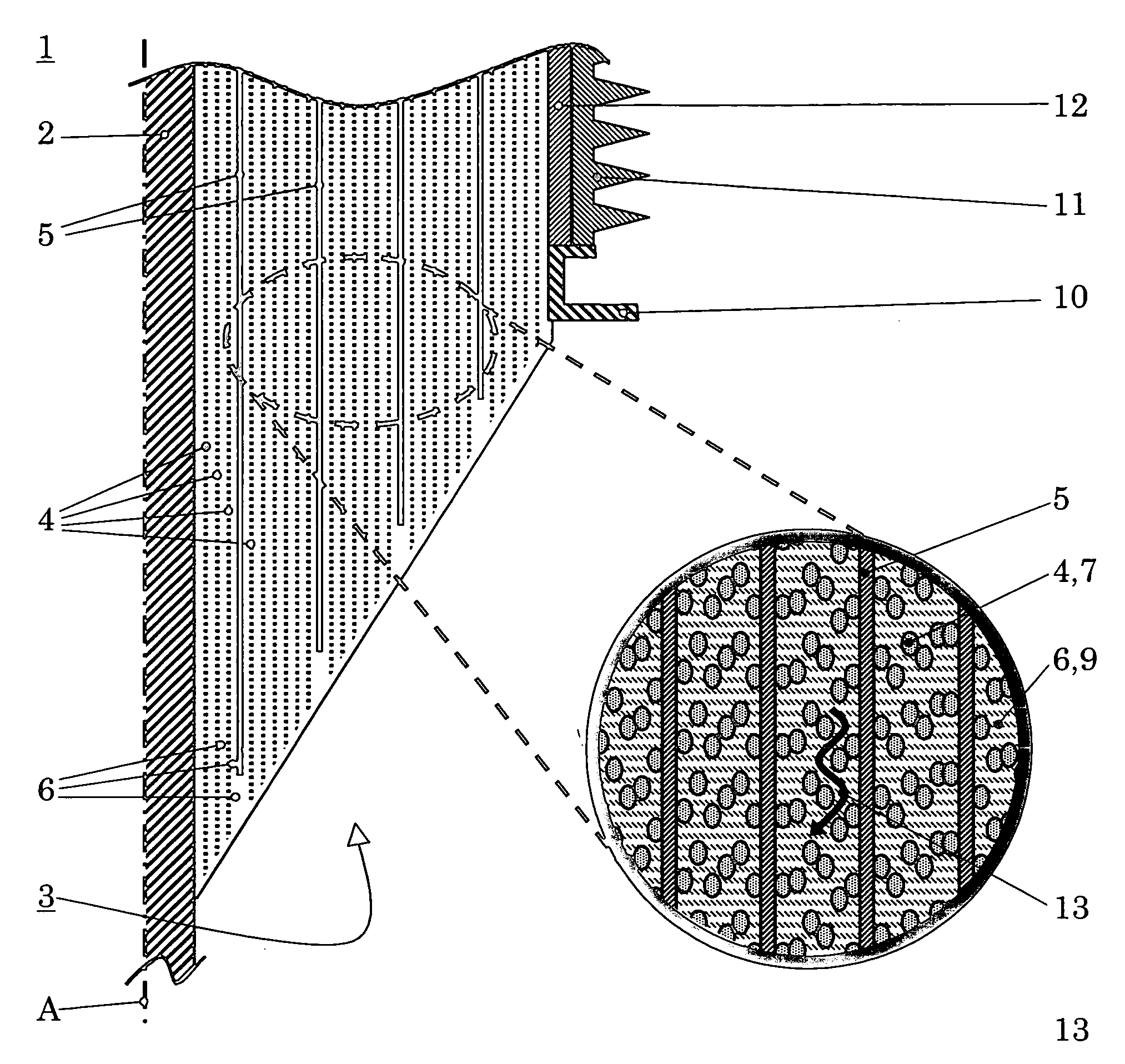

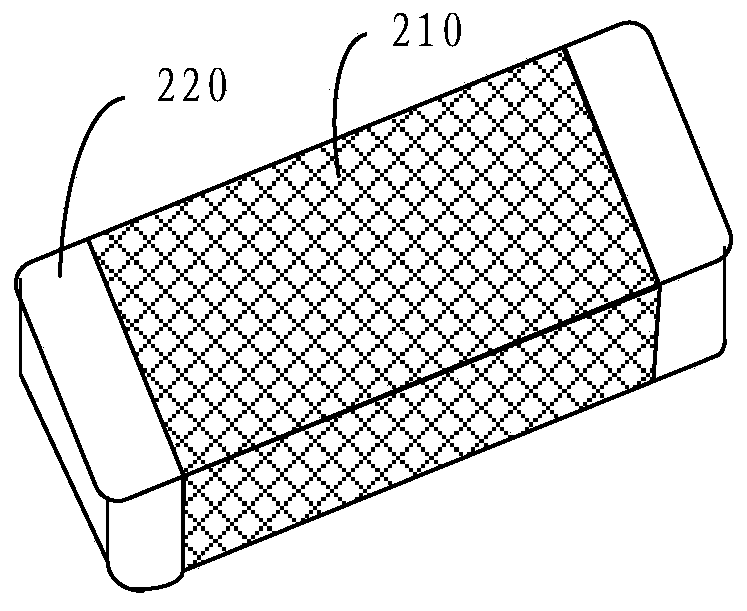

High-voltage bushing

ActiveUS20070158106A1Less epoxyShorten the timeOptical light guidesLead-in/lead-through insulatorsFiberElectrical conductor

An exemplary high-voltage bushing has a conductor and a core surrounding the conductor, wherein the core includes a sheet-like spacer, which spacer is impregnated with an electrically insulating matrix material. The spacer can have a multitude of holes that are fillable with the matrix material. The spacer can be net-shaped or meshed. It can be a net of fibers. The bushing can be a fine-graded bushing with equalizing plates within the core. As a matrix material, a particle-filled resin can be used.

Owner:HITACHI ENERGY SWITZERLAND AG

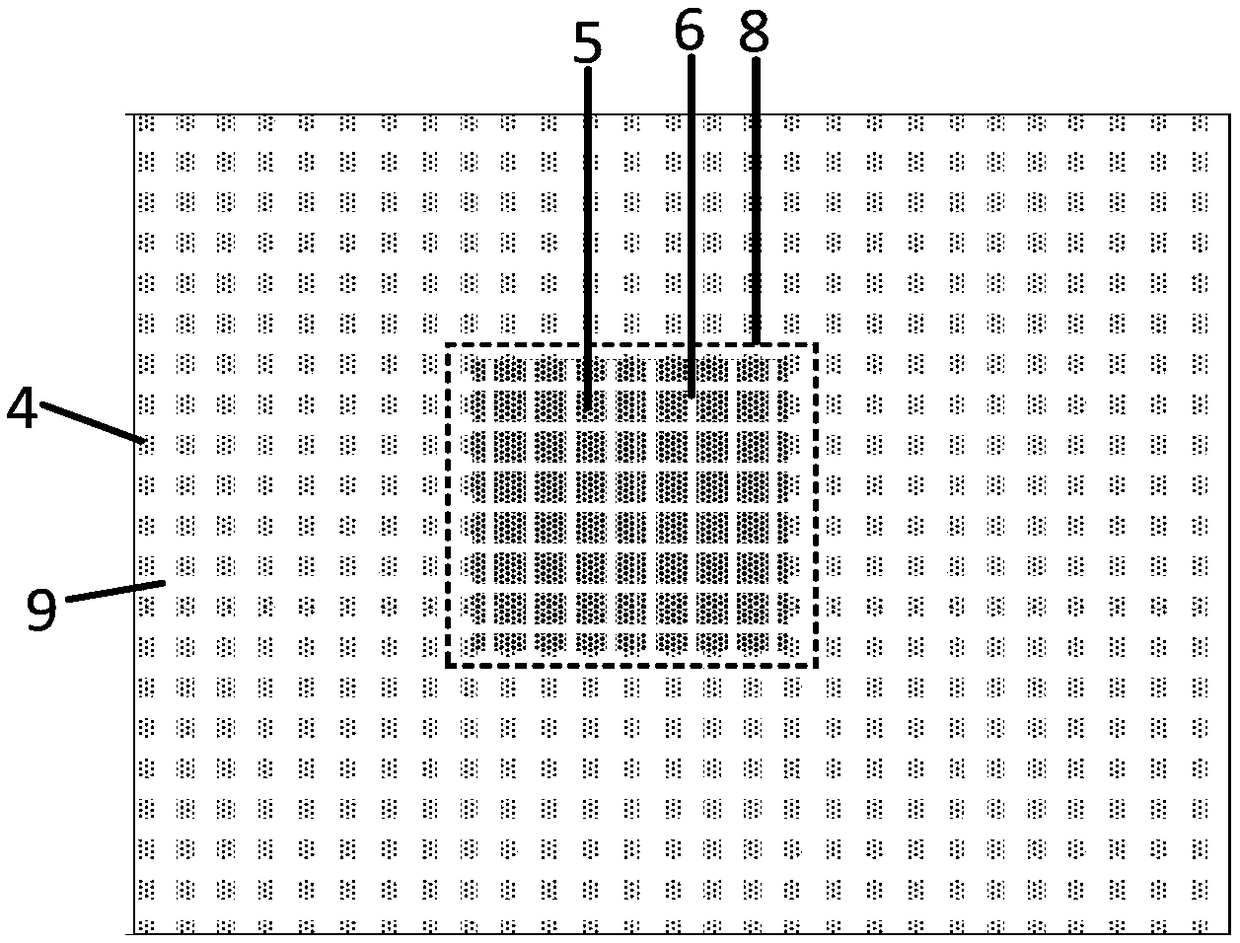

High density power/lighting panelboard

ActiveUS20110304958A1Increase rangeIncrease the rated currentBus-bar/wiring layoutsSubstation/switching arrangement boards/panels/desksElectricityHigh density

A panelboard supplies electricity to multiple loads, such as lighting fixtures and / or other electrical devices via one or more high-amperage circuit breakers and one or more low-amperage circuit breakers. The panelboard includes one or more vertical busbars and one or more horizontal busbars coupled together in a single housing. The one or more horizontal busbars are coupled to a main input breaker that receives electricity from a source. The main input breaker distributes the electricity to the horizontal busbars. The horizontal busbars distribute the electricity to the high-amperage circuit breakers coupled thereto and to the vertical busbars. The vertical busbars distribute the electricity to the low-amperage circuit breakers coupled thereto.

Owner:SCHNEIDER ELECTRIC USA INC

Silicon carbide schottky diode for optimizing heat distribution and method of manufacturing the same

PendingCN109244146AReduce the temperatureIncrease the rated currentSemiconductor/solid-state device manufacturingSemiconductor devicesCarbideSchottky diode

The invention relates to the technical field of semiconductors, and discloses a silicon carbide Schottky diode for optimizing heat distribution and a method for manufacturing the same. A cathode motor, an N-type silicon carbide substrate, an N-type epitaxial lay and an anode electrode are sequentially arranged from bottom to top; the upper surface of the N-type epitaxial layer is formed with a current suppressing region in the middle, A plurality of second P-type well regions are spaced apart in the current suppression region, and a plurality of first P-type well regions are spaced apart on anupper surface of an N-type epitaxial layer around the current suppression region, wherein the area proportion of the second P-type well regions in the current suppression region is larger than that of the first P-type well regions on the chip-removed current suppression region. By reducing the current density in the center of the chip, the invention obviously reduces the temperature in the centerof the chip, so that the temperature distribution of the chip is uniform and the rated current of the device is improved.

Owner:WUXI NCE POWER

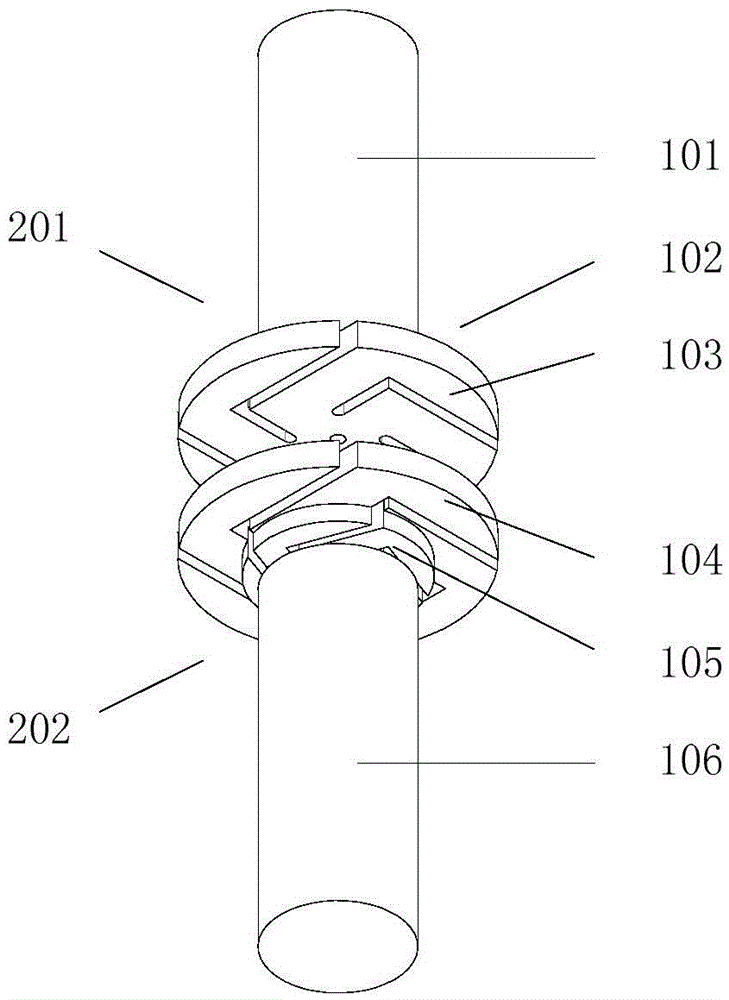

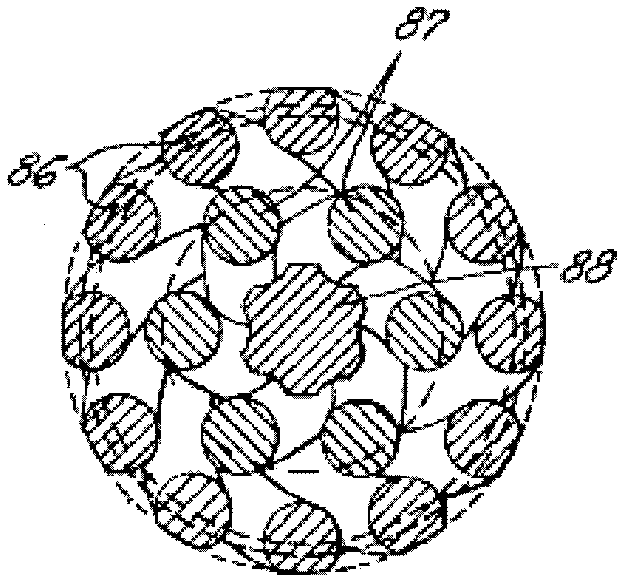

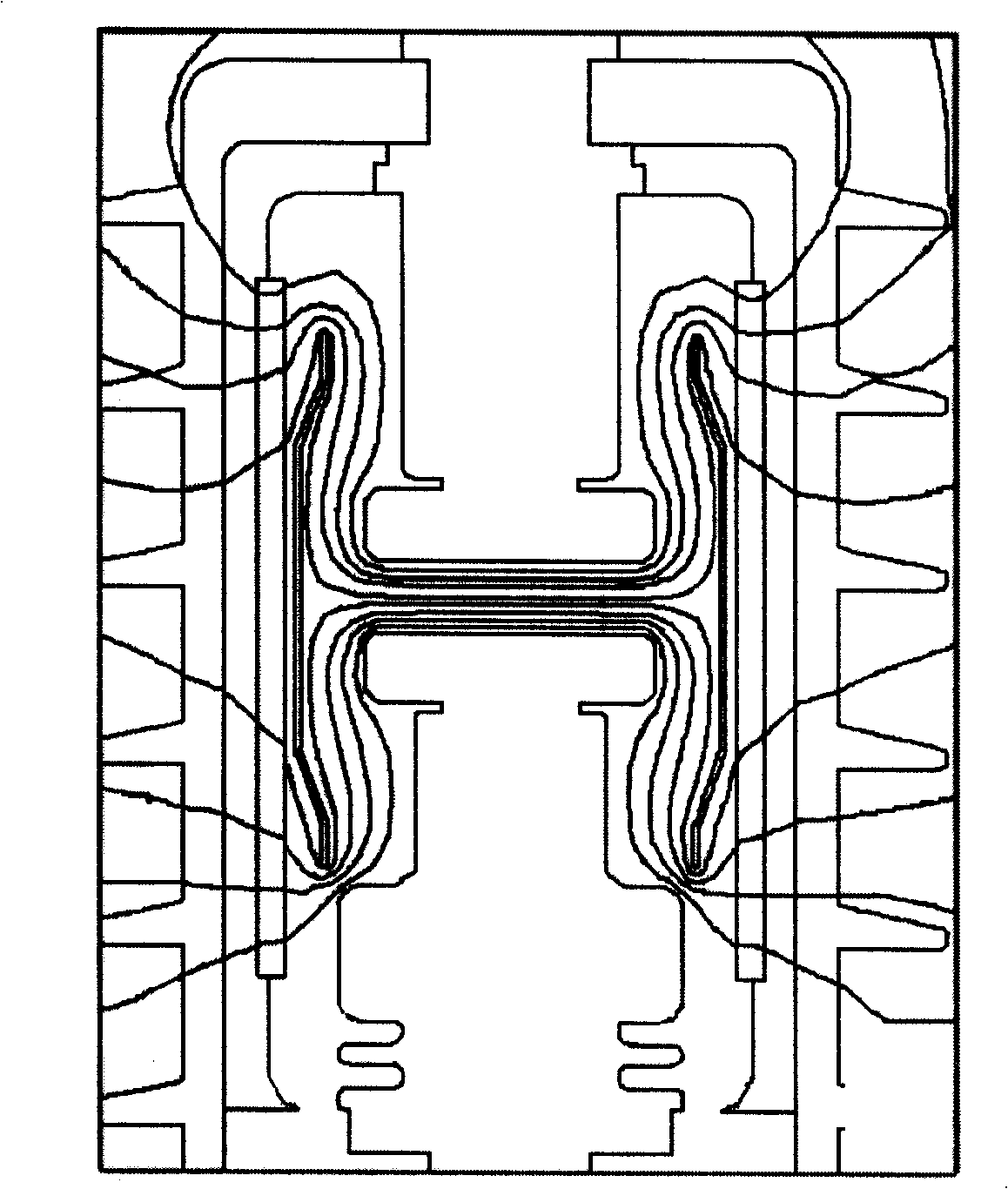

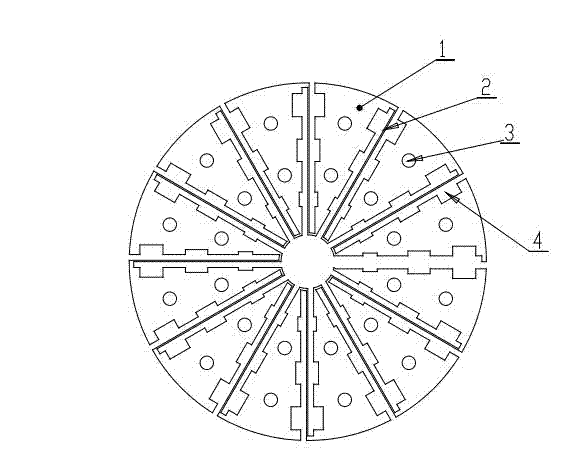

Novel permanent-magnet composite magnetic field contact structure and vacuum arc-extinguishing chamber employing same

ActiveCN105529210AEasy to controlFully consider the control characteristicsHigh-tension/heavy-dress switchesAir-break switchesTransverse magnetic fieldSurface structure

The invention provides a novel permanent-magnet composite magnetic field contact structure and a vacuum arc-extinguishing chamber employing the same. The contact structure comprises a pair of transverse magnetic field contact blades and a pair of permanent-magnet composite structures, wherein the pair of permanent-magnet composite structures is arranged at the back of the transverse magnetic field contact blades; a magnetic field is generated by a contact gap after static-end permanent-magnet groups and running-end permanent-magnet groups are coordinated with each other; and the magnetic fields generated by a static-end transverse magnetic field contact blade and a running-end transverse magnetic field contact blade in an arcing process act on an electric arc, so that effective control on the electric arc is achieved. According to the novel permanent-magnet composite magnetic field contact structure and the vacuum arc-extinguishing chamber, the problems that the structure of the contact surface is too complicated and the electric arc control ability of a permanent magnet is limited in existing composite magnetic field contact structure and permanent-magnet contact structure are solved.

Owner:XI AN JIAOTONG UNIV

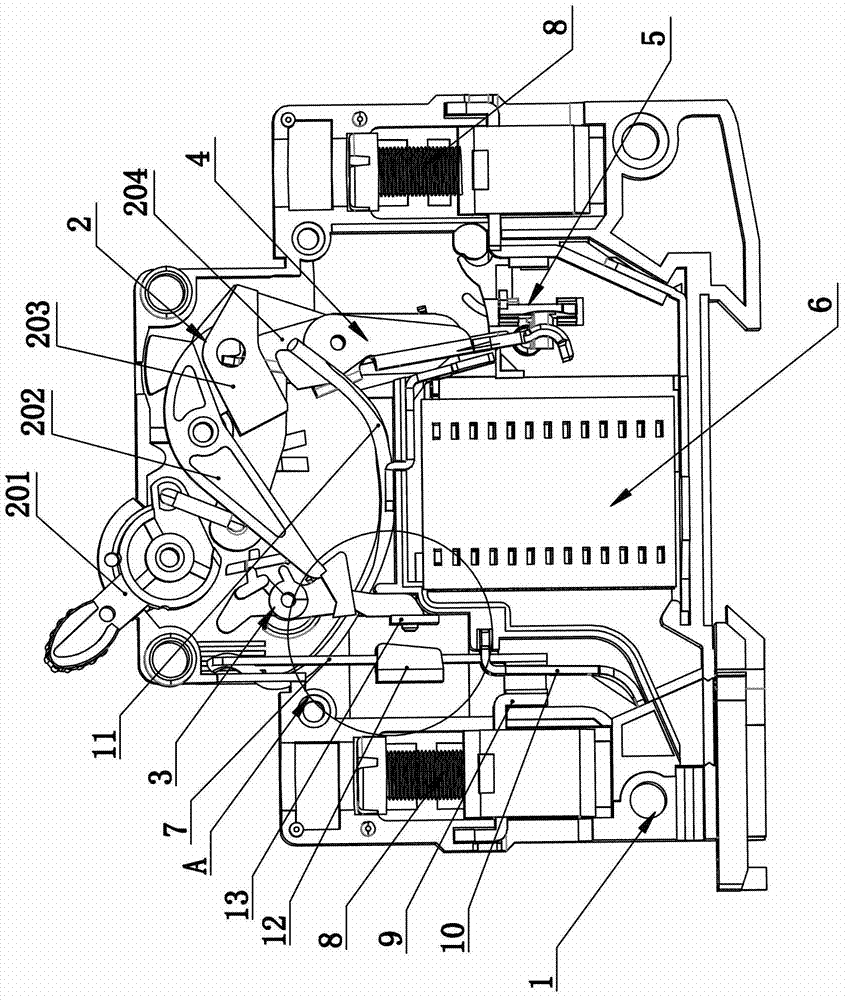

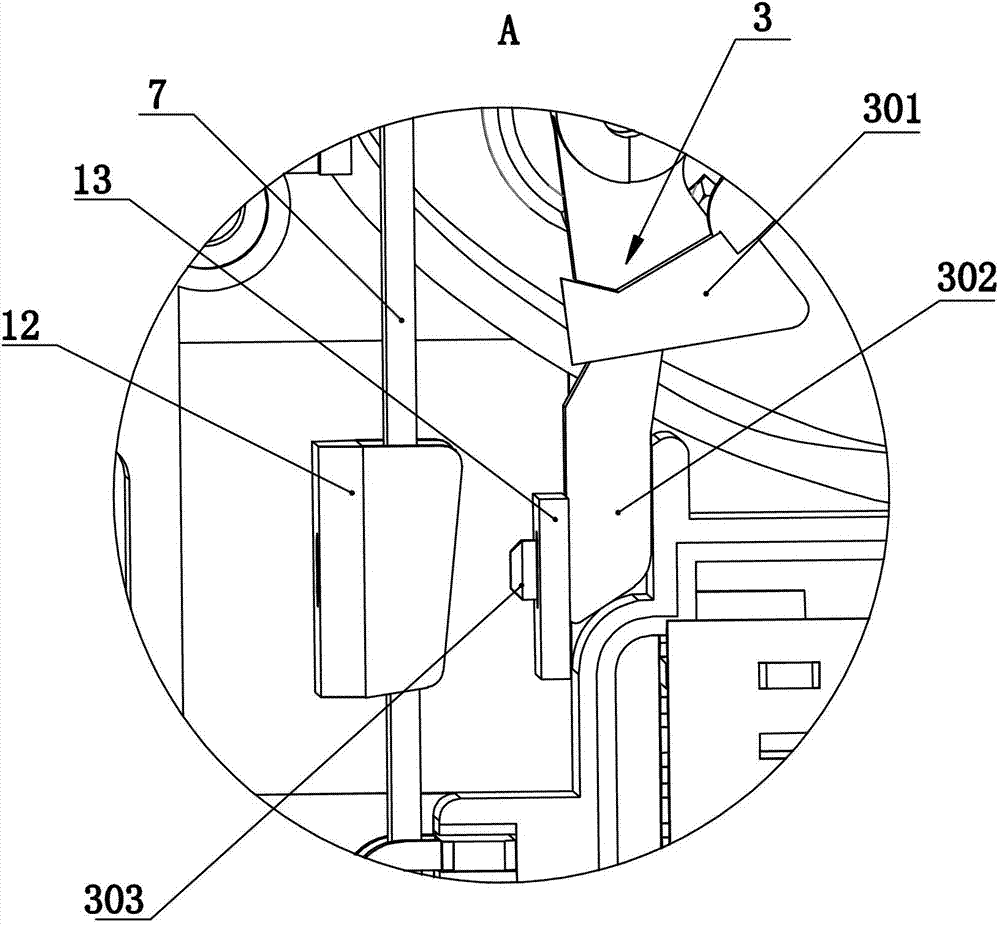

Intelligent circuit breaker combined device

ActiveCN105513915AOvercome failureLower internal resistanceSnap-action arrangementsContactsIntelligent controlPower consumption

The invention provides an intelligent circuit breaker combined device. A current detecting piece is arranged in a circuit breaker. The current value of a circuit in the circuit breaker is obtained through the current detecting piece and then sent into a controller of an intelligent control device on one side of the circuit breaker, and the controller makes a judgment according to the received current value, and controls and starts an action mechanism to drive the circuit breaker to be released when the current value is in an overload state for a period of time. Because the current value of the circuit in the circuit breaker is directly tested and the controller is used for intelligent control, the problem that a thermal releaser is prone to fails caused by the external environment air temperature influences is solved. Meanwhile, due to the fact that the thermal releaser is omitted, the internal resistance of the circuit breaker is greatly reduced, and the power consumption and the heating amount of the circuit breaker are reduced. In addition, the controller is independently arranged in the intelligent control device outside the circuit breaker, the problem that a controller can not be put in a narrow space of a circuit breaker is solved, and meanwhile it can be avoided that the work of a controller is influenced by strong current.

Owner:JAECELE ELECTRIC

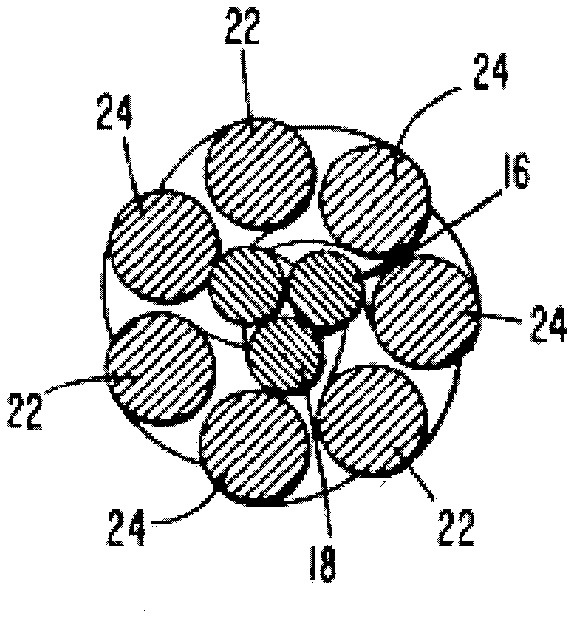

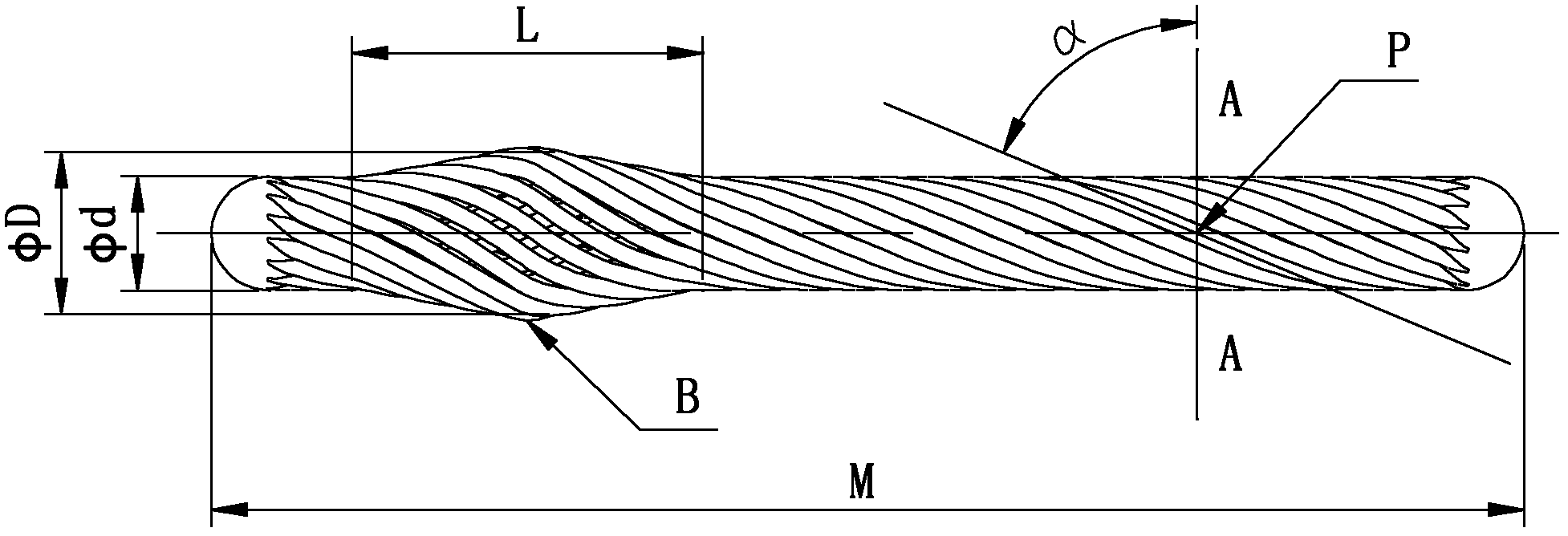

Stranded wire-type elastic contact pin

ActiveCN102570117AReduce meshing forceSmall insertion forceCoupling contact membersCentral layerMetal

Owner:GUIZHOU SPACE APPLIANCE CO LTD

High voltage vacuum circuit breaker with high rated current

InactiveCN1963971AIncrease the rated currentHigh thermal conductivityHigh-tension/heavy-dress switchesAir-break switchesHigh rateEvaporation

The invention relates to a high-voltage vacuum breaker for high rated current. Wherein, the vacuum arc-extinguish chamber pole includes the ceramic sleeve for insulation to accommodate the chamber, a static conductive pole on one chamber end with an upper conductive ring and flange, a movable pose on another end with an lower conductive ring and conductive support with lower flange, two wire terminals on sleeve to connect former conductive rings; a first and second radiator near two flanges respectively; some insulation oil between the sleeve and chamber and the support; some evaporation holes on static pole supported by stainless steel, some refluence holes under evaporation holes, and some liquid working medium.

Owner:XI AN JIAOTONG UNIV

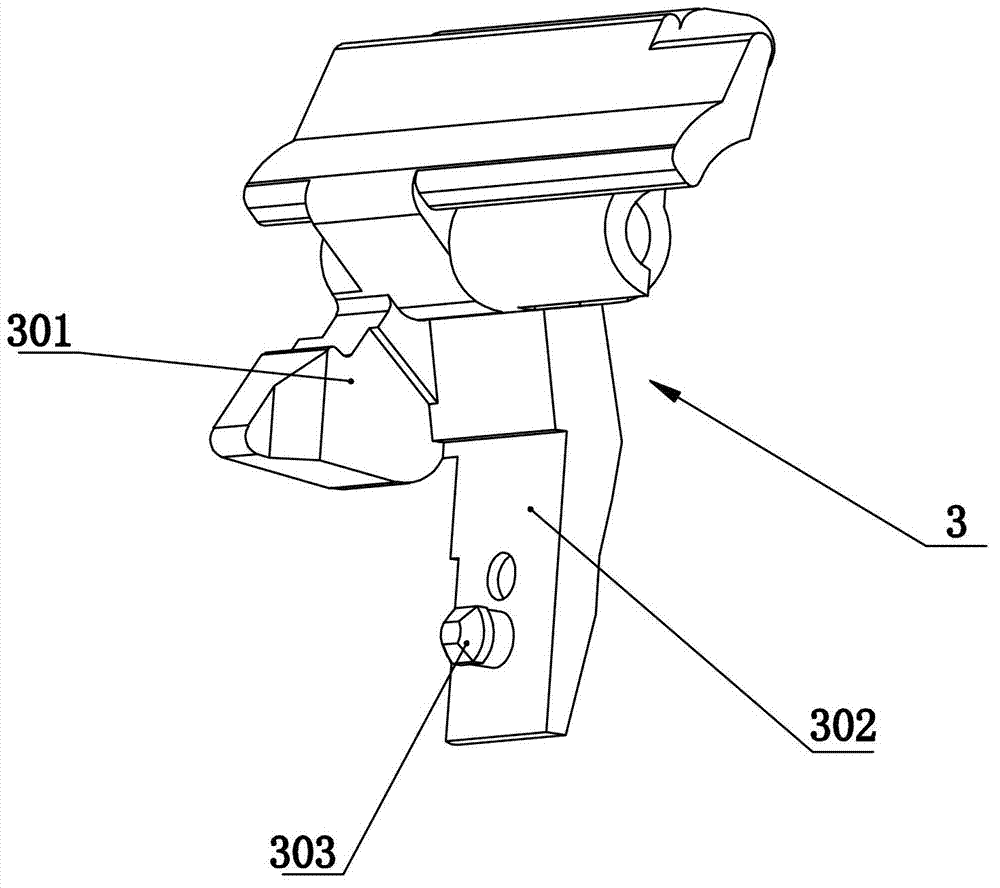

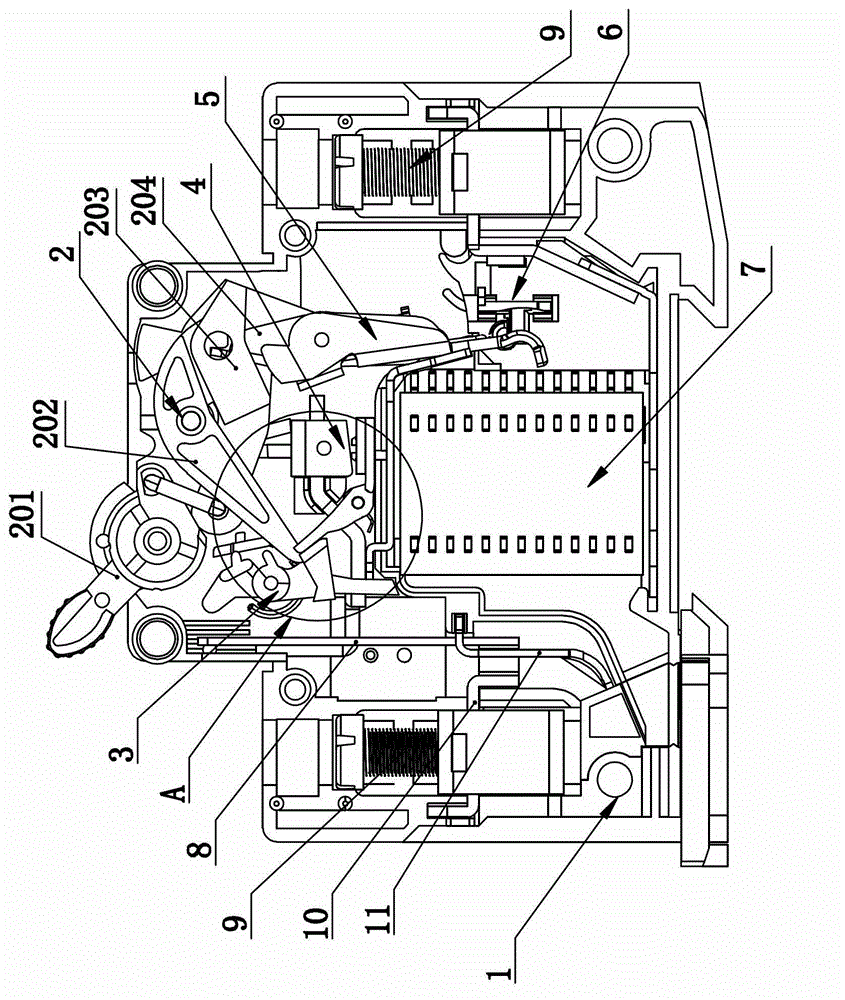

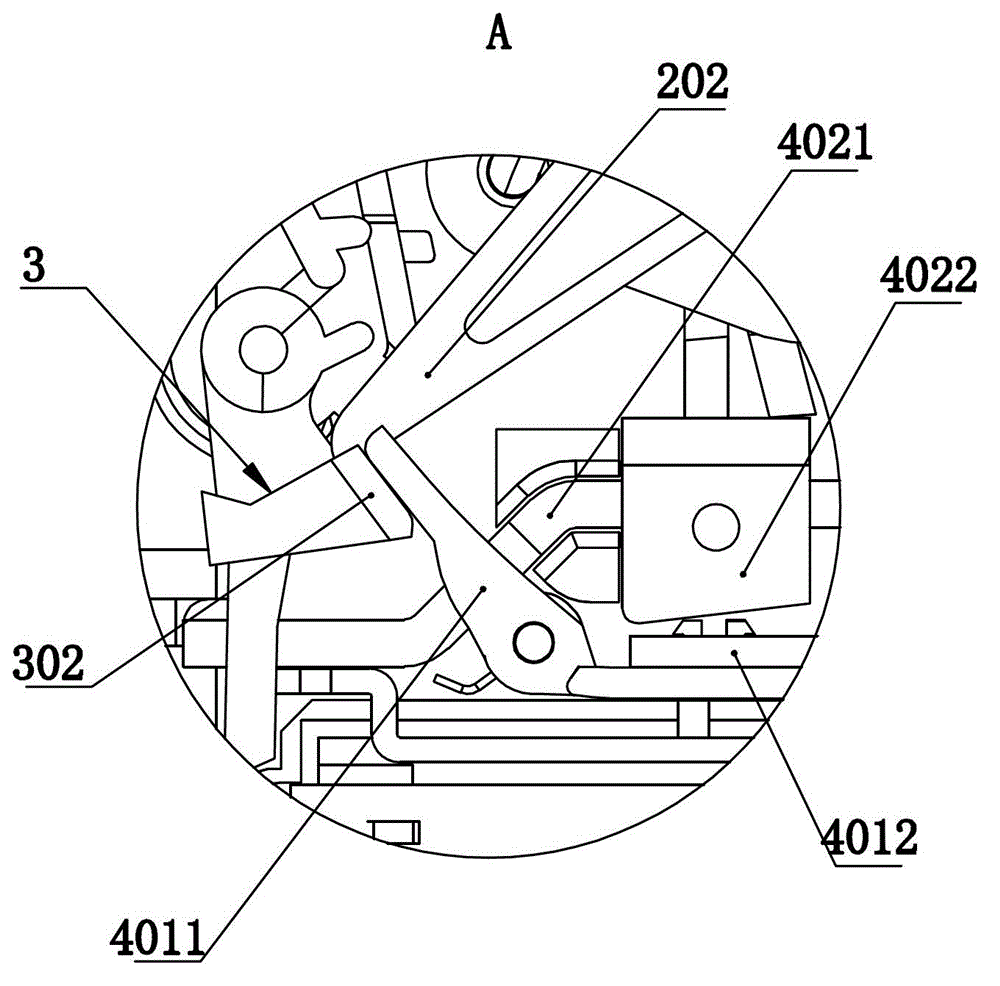

Large-current miniature circuit breaker

ActiveCN102820182ASimple structureIncrease in sizeProtective switch operating/release mechanismsEngineeringBreaking capacity

The invention relates to a large-current miniature circuit breaker, which comprises a shell. An operating mechanism, a plastic lock catch support, a tripping mechanism, a moving contact, a fixed contact, an arc extinguishing chamber and a bimetal sheet are arranged in the shell. Wiring terminals are respectively arranged on the two sides of the internal part of the shell. The plastic lock catch support is hinged in the shell. The plastic lock catch support comprises a lock catch part which is matched with the operating mechanism and an instantaneous tripping part which is matched with the tripping mechanism. The tripping mechanism comprises an electromagnetic induction element and an armature. The electromagnetic induction element is matched with the bimetal sheet. The armature is fixedly arranged at the instantaneous tripping part of the plastic lock catch support and is matched with the electromagnetic induction element. By adopting the technical scheme, the large-current miniature circuit breaker has the effects that the structure is simple, the cost is lower, and the breaking capacity and the rated current are greatly improved.

Owner:WENZHOU NEW BLUD SKY ELECRICIAL

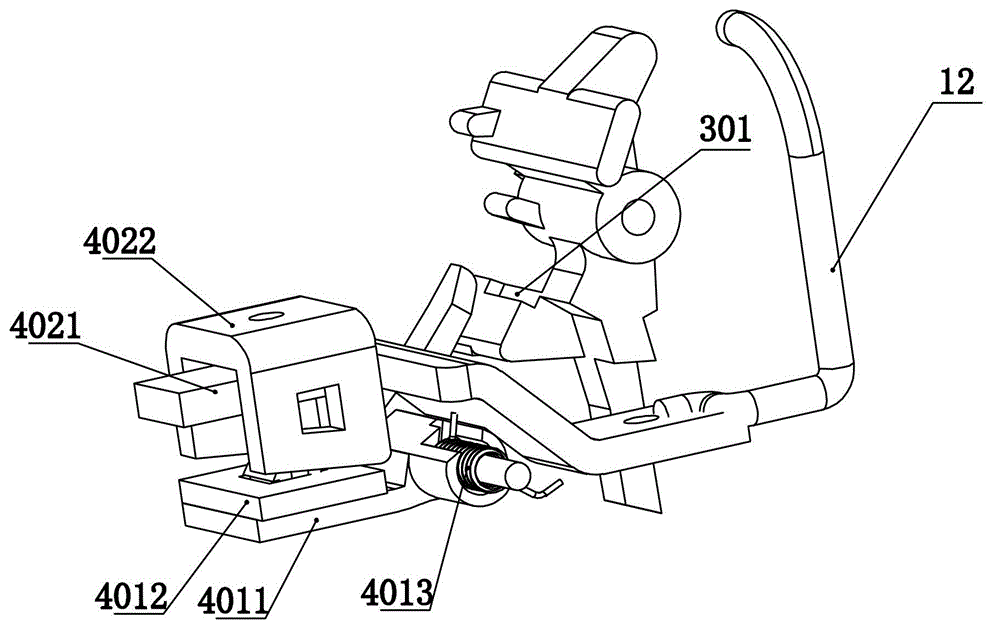

Crow plate trip circuit breaker

ActiveCN102915890ASimple structureReduce manufacturing costProtective switch operating/release mechanismsElectricityPower flow

The invention relates to a crow plate trip circuit breaker which comprises a housing, an operating mechanism, a latch frame, a trip mechanism, a moving contact, a static contact, an arc extinguish chamber and double sheet metals, wherein the latch frame is hinged inside the housing and comprises a latch part matched with the operating mechanism and an action part matched with the trip mechanism, the trip mechanism comprises a crow plate unit and a driving unit used for driving the crow plate unit to rotate, the driving unit comprises a conducting plate electrically connected with the double sheet metals and an electromagnetic induction element arranged on the conducting plate, the crow plate unit comprises a pivotally arranged crow plate, an armature matched with the electromagnetic induction element is arranged at one end of the crow plate, the other end of the crow plate is matched with the action part of the latch frame, and the crow plate is also provided with an elastic part used for applying acting force to the crow plate. The technical scheme of the crow plate trip circuit breaker has the effects of simple structure, lower cost and greatly increased breaking capacity and rated current.

Owner:WENZHOU NEW BLUD SKY ELECRICIAL

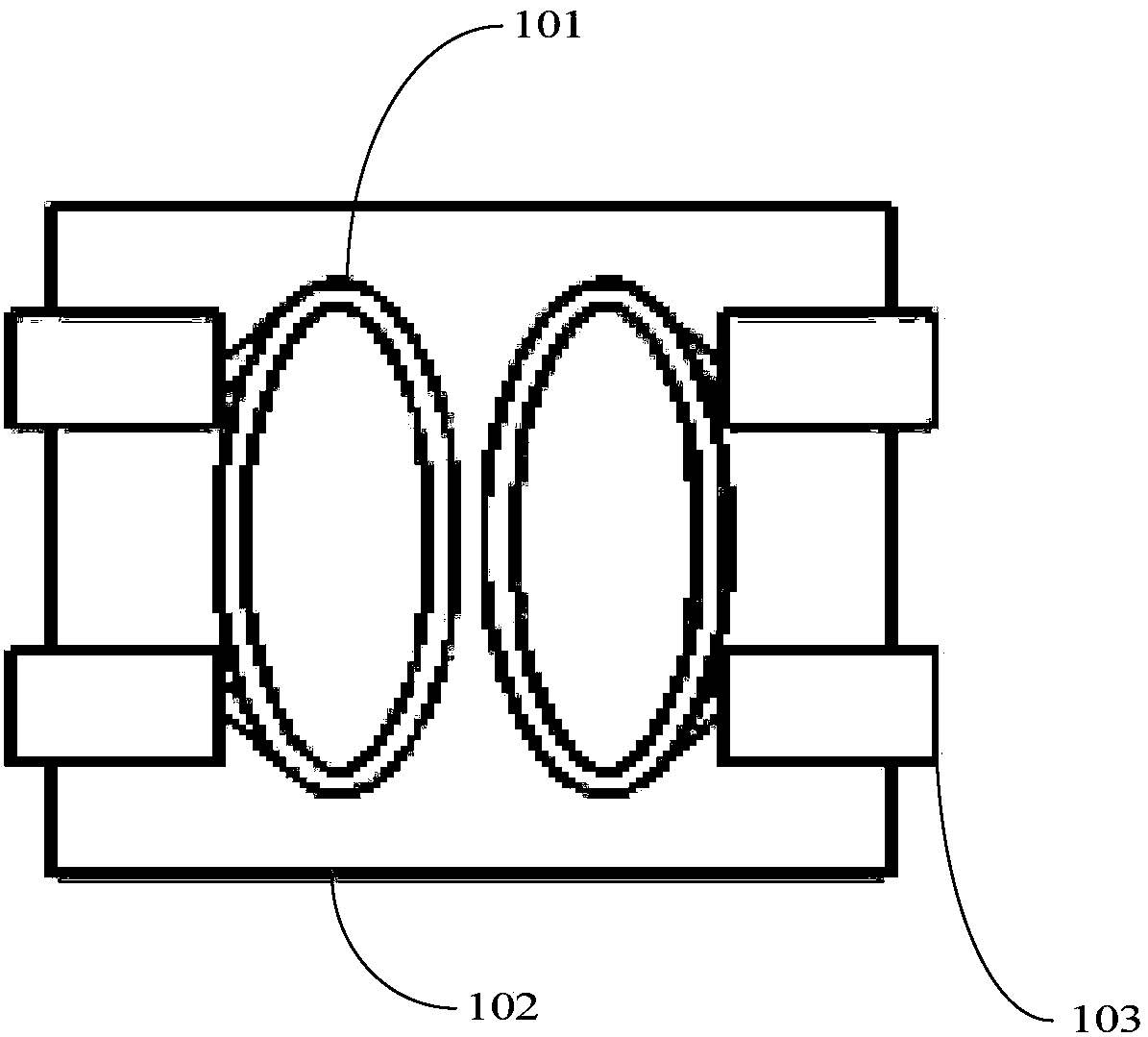

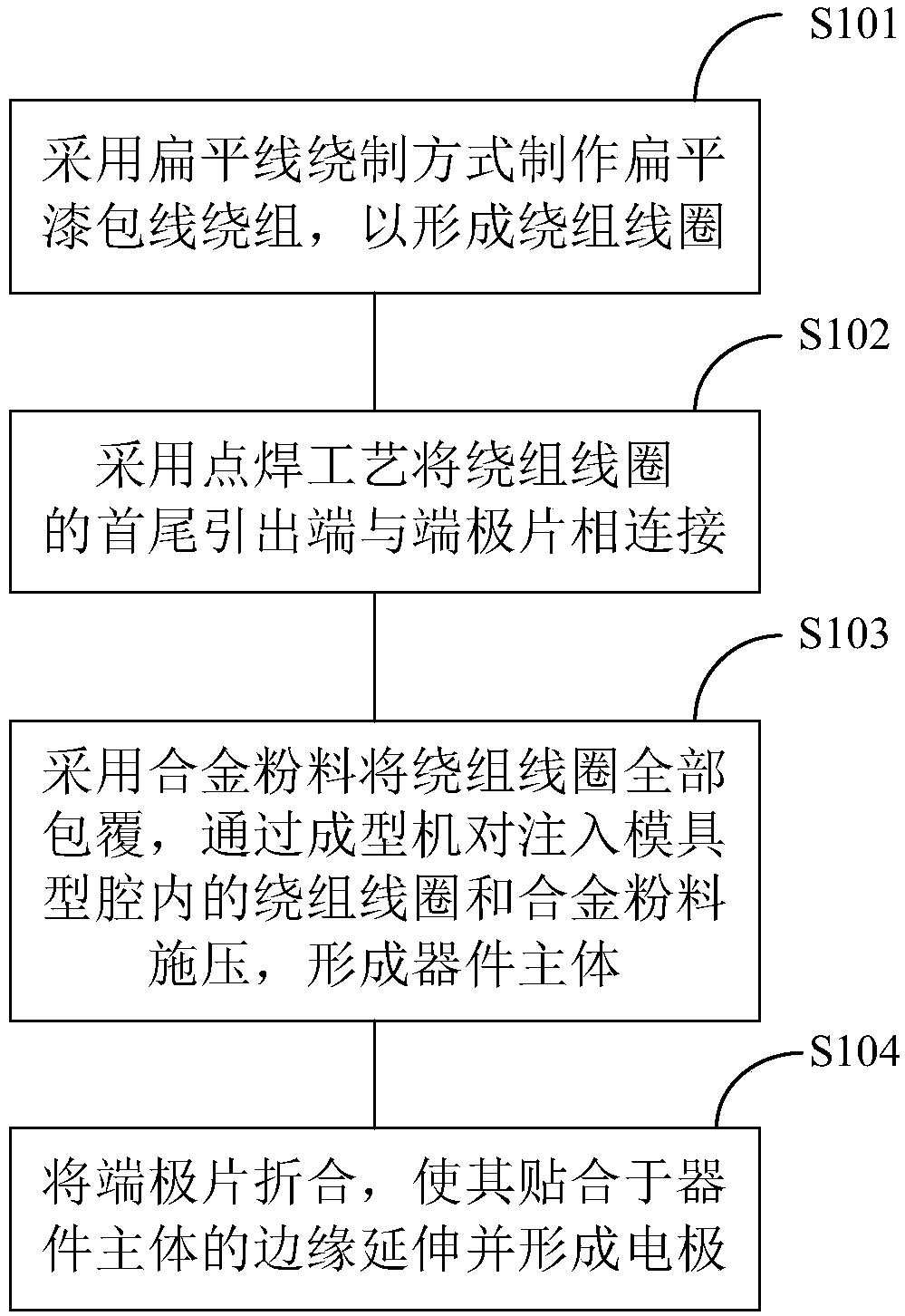

Common mode inductor and manufacturing method thereof

PendingCN107799271AReduce DC resistanceNot easy to get hotTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureOvercurrentInductor

The invention belongs to the technical field of inductor technologies, and provides a common mode inductor and a manufacturing method thereof. The common mode inductor comprises a magnetizer, end polepieces and two winding coils; the two winding coils are wound by flat wires, direct current resistance is reduced, the common mode inductor is not prone to heating when currents pass accordingly, rated currents of the common mode inductor are improved, and the requirements of low direct current resistance and the high rated currents of the inductor are met; leading-out terminals of the two winding coils and the end pole pieces are welded, the winding coils are wrapped with the magnetizer, the magnetizer and the winding coils are integrally formed, and the common mode inductor is high in strength and impact resistance capacity accordingly; the end pole pieces extend outside the magnetizer and form electrodes of the common mode inductor, and when the certain magnetic conductivity of the magnetizer is guaranteed, the temperature coefficient can be 180 DEG C, and the common mode inductor can work at the high temperature or the low temperature accordingly; the problems that an existing common mode inductor is poor in vibration resistance capacity and impact resistance capacity and cannot work in the high-temperature state are solved.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS +1

Quick fuse for protection of semiconductor devices

InactiveCN102403173AStable fusing characteristicsReliable protectionEmergency protective devicesEngineeringSmall hole

The invention discloses a quick fuse for protection of semiconductor devices, which comprises a fusion tube, a plurality of fusion sheets, arc extinguishing media and a pair of contact plates. A cavity is axially arranged on the central end face of the fusion tube, a solder bridge is arranged on the surface of each fusion sheet, multicolumn large holes are uniformly arranged at intervals on the surface of the each fusion sheet, small holes in column are arranged beside each column of large holes, each column of large holes comprises a plurality of large-diameter holes with same sizes, and each column of small holes comprises a plurality of small-diameter holes with same sizes. The large holes in column close to the length center of the corresponding fusion sheet are transverse elongated holes, and another column of small holes is further arranged between the column of elongated holes and the column of small holes close to the elongated holes. Each fusion sheet is bent into a square wave shape with center lines of the large holes in column and the small holes in column serving as folding lines, and then inserted into the cavity of the fusion tube after being enclosed into a shape with an open equilateral polygonal section. The arc extinguishing media are filled between a cavity of each fusion sheet and the corresponding fusion sheet, and the contact plates in pair are fastened to two ends of the fusion tube.

Owner:上海电器陶瓷厂有限公司

Electronic Leakage Circuit Breaker

ActiveCN107146745BTake advantage ofIncrease the rated currentProtective switch operating/release mechanismsEngineeringCircuit breaker

Owner:ZHEJIANG CHINT ELECTRIC CO LTD +1

Power inductor and manufacturing method thereof

ActiveCN102082019ALarge inductor rated currentIncrease the rated currentInductances/transformers/magnets manufactureFixed signal inductancesInductorElectronic component

The invention discloses a chip type power inductor and a manufacturing method thereof. The inductor comprises a substrate, an inductance coil, a terminal stud and a dielectric layer, wherein the inductance coil is arranged in the substrate in a stacking manner, and both ends of the inductance coil are respectively connected with the terminal stud; and the dielectric layer is arranged in the substrate and separates the power inductor into an upper layer and a lower layer. After the inductor is formed by adopting a casting process and a lining electrode printing process, a finished product is manufactured through low temperature cofiring. Through the special air gap action of the dielectric layer, the characteristics of the stacking inductor are improved, and the DC bias characteristic and the flow resistance characteristic of the stacking power inductor are increased. Compared with a wound power inductor, the stacking power inductor is easier to reduce element size and thickness. The chip type power inductor is applicable to the development of new electronic elements, fills up the national blankness on such components, and has innovation in the aspects of materials, design, processes, measurement and the like. The product has advanced design, a self-developed process route is adopted, and the performance of the product can reach the international advanced level.

Owner:SHENZHEN MICROGATE TECH

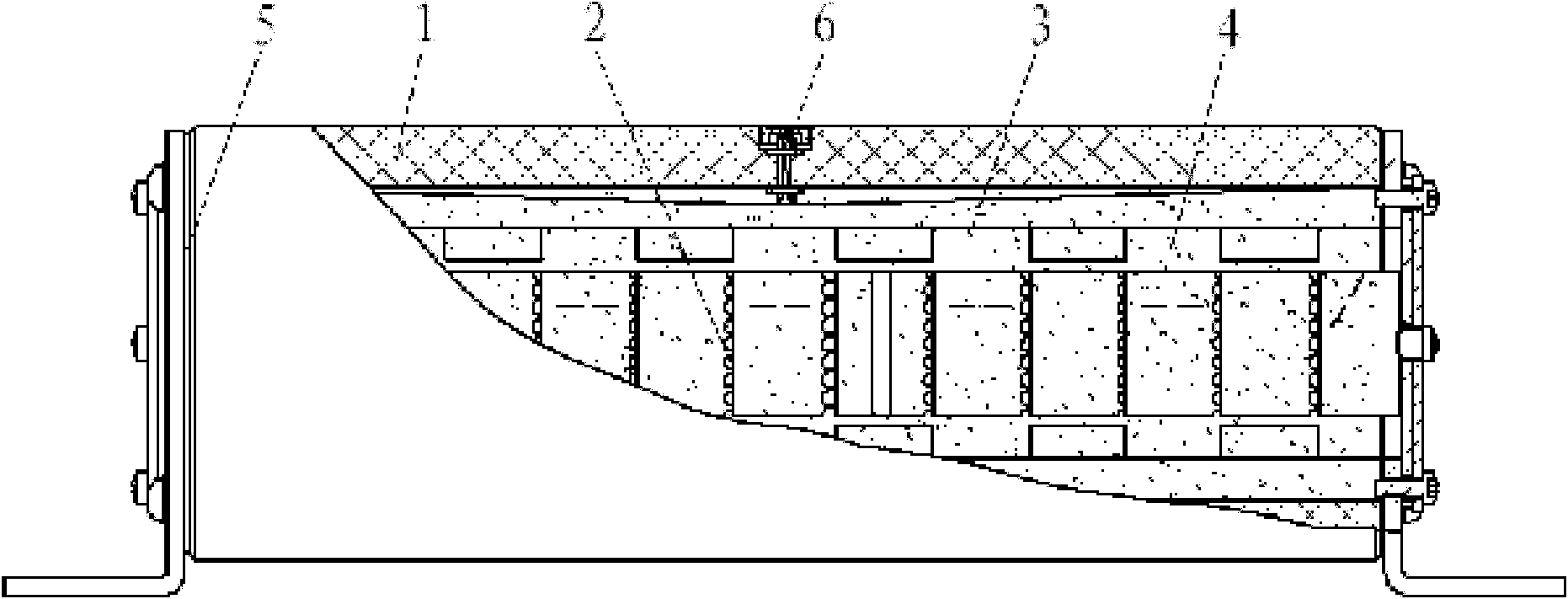

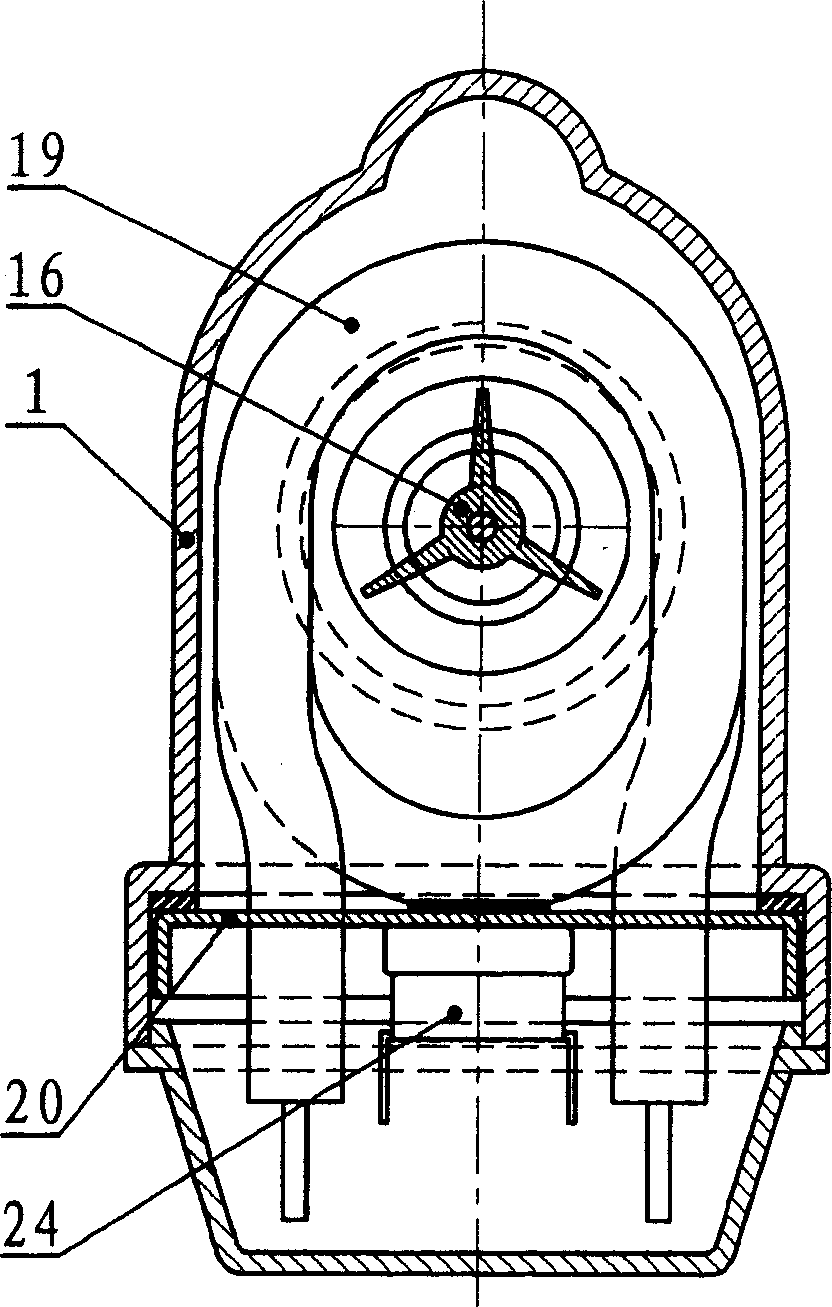

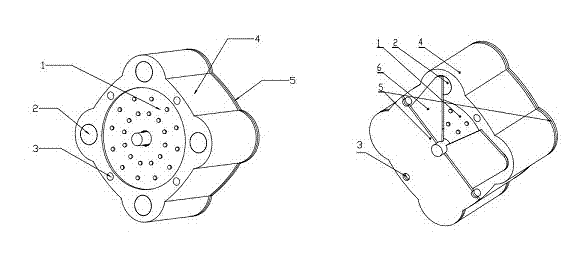

Circular preheater of permanent magnet rotary pump in single cavity, and assembly method

ActiveCN1760535ASmall footprintSmall sizeMachines/enginesEngine startersPermanent magnet rotorImpeller

A circulating preheater with single cavity permanent magnet rotor ( PMR ) pump is featured as preparing cavity body rotor and cavity shell by plastic injection molding for setting then in one body or one body connected structure ; setting outlet , front head opening , electro thermal tube ( ET ) opening at bottom and separated stator slot on cavity body ; installing PMR , front hearing and impeller in rotor or heating cavity from front head opening ; installing ET spiral portion in heating cavity from its own opening ; filling and sealing stator in stator slot ; setting temperature sensing component on external side surface of ET fixture disc and setting junction box below ET fixture disc and stator slot . The ET should be installed first when assembling operation is carried out.

Owner:青岛快乐电气有限公司

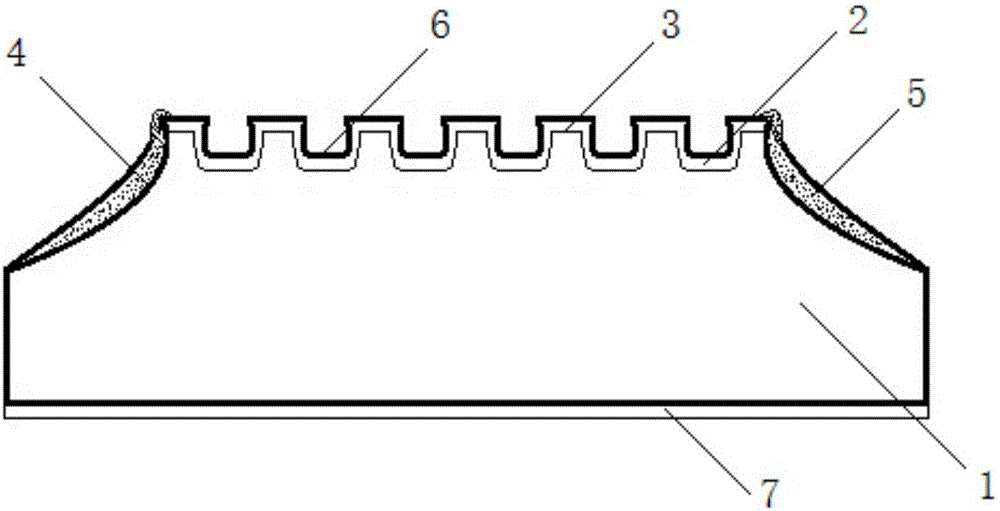

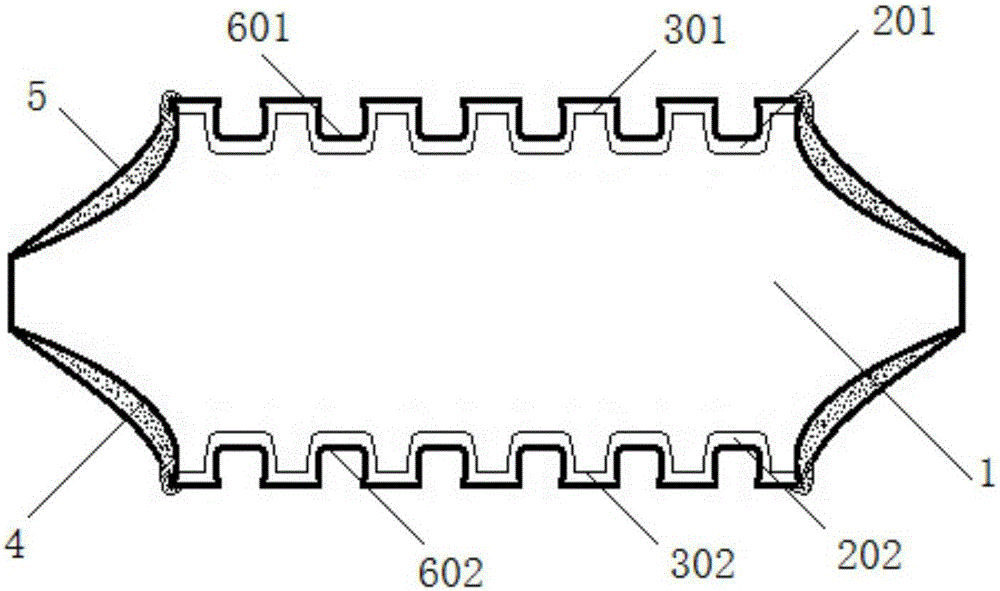

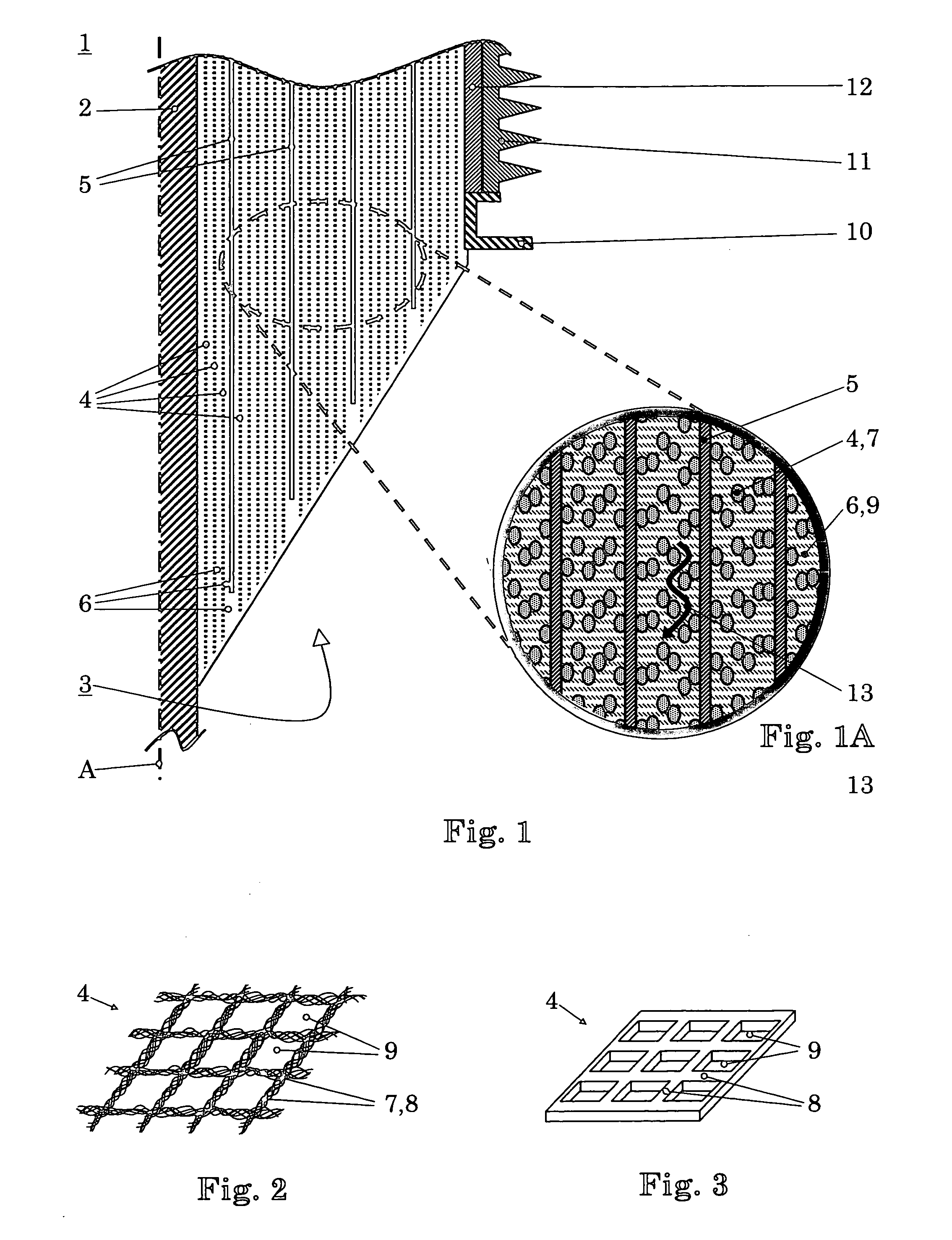

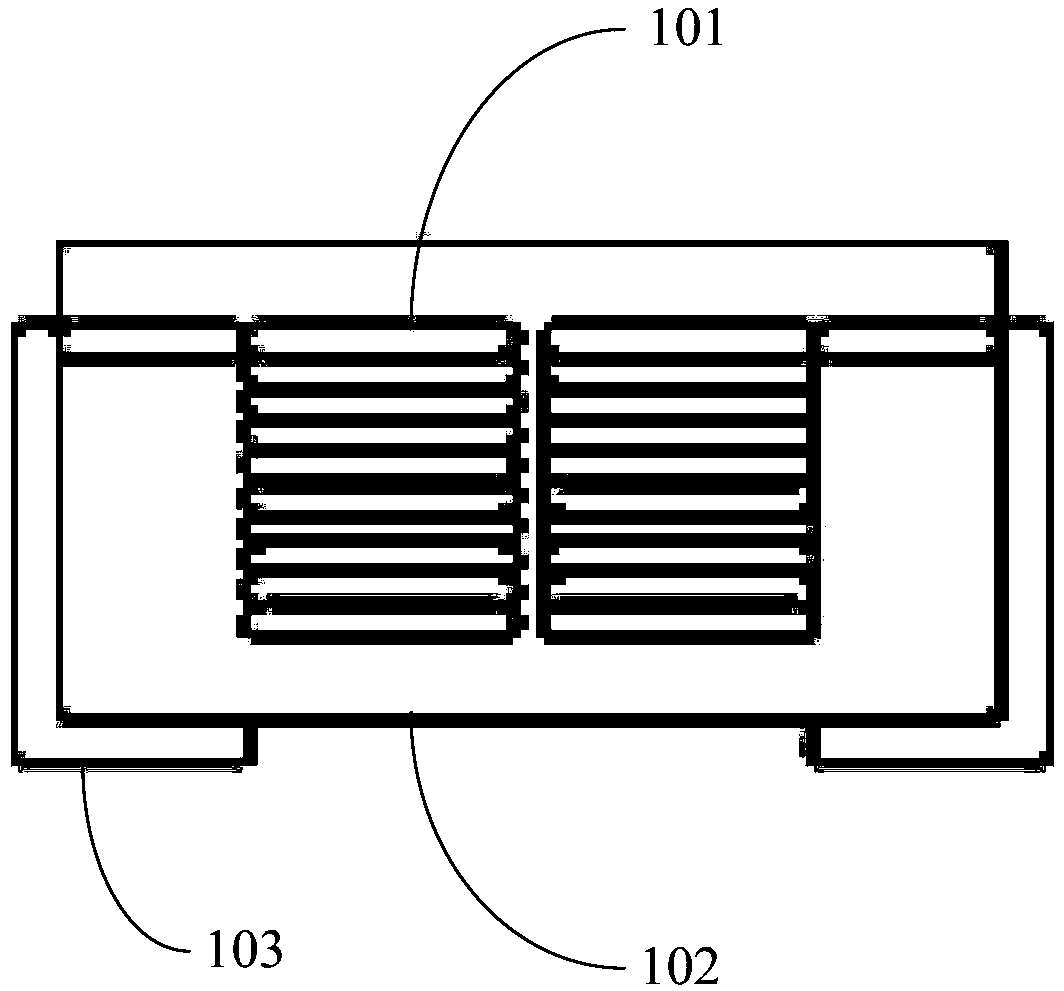

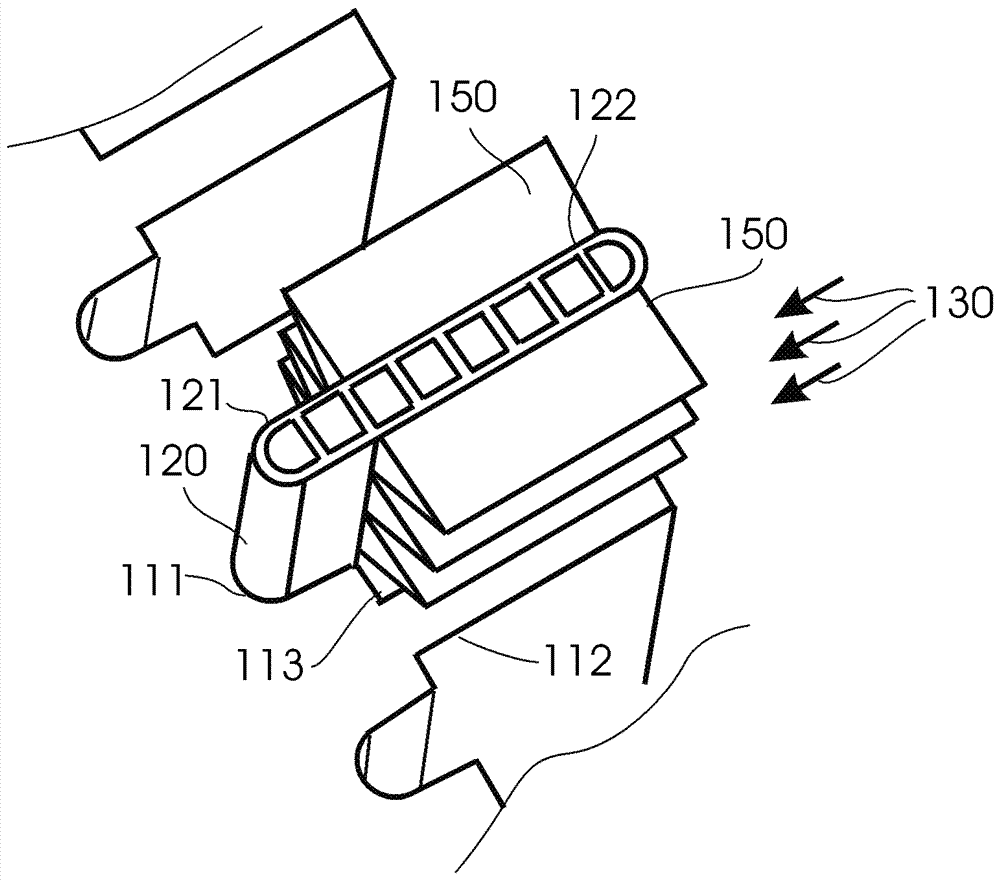

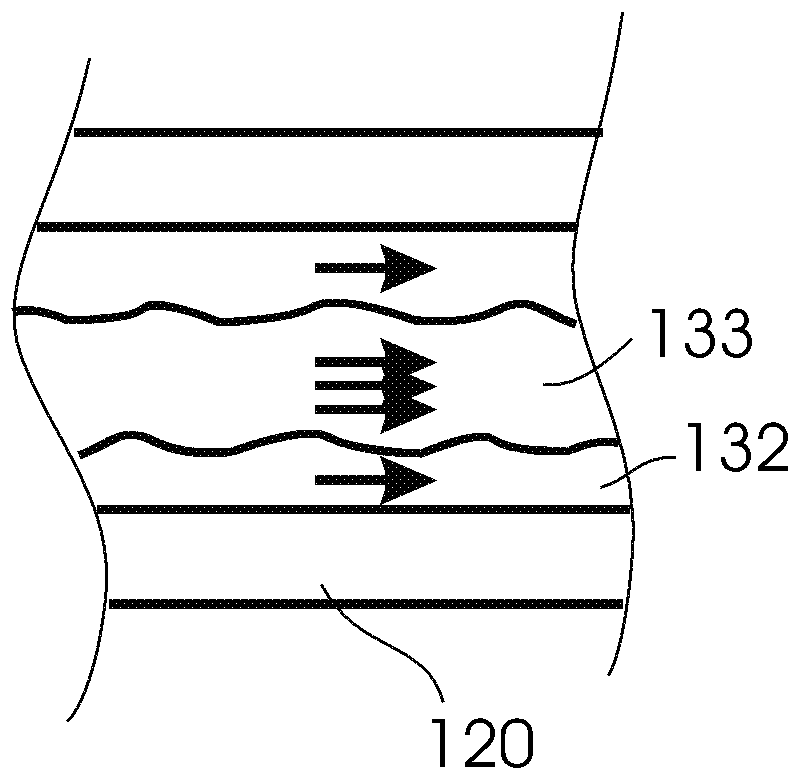

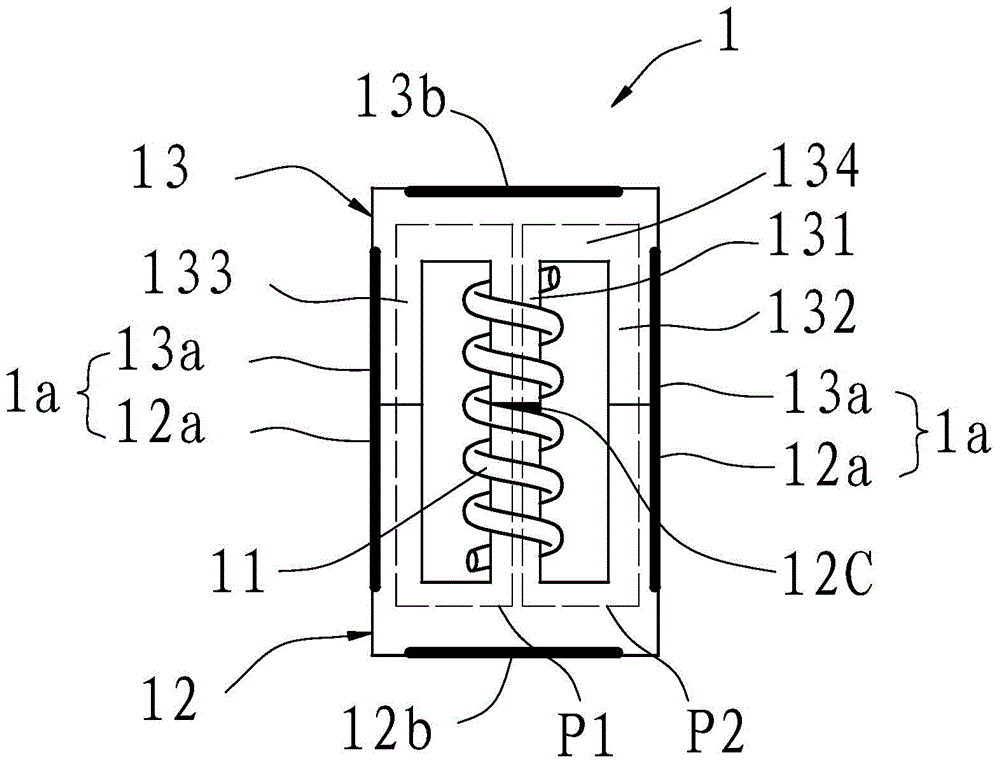

Heat exchanger for power-electronic components

ActiveCN106954366AAchieve thermal separationIncrease the rated currentThermal insulationIndirect heat exchangersElectronic componentThermal contact

It is proposed a two-phase heat exchanger device (100) for a power-electronic module arrangement having a semiconductor module. The two-phase heat exchanger device includes a base plate (110) configured for being in contact with a first semiconductor module (201) at a first side (123) of the base plate; and at least one tube element (120) for a first cooling medium (131) including a first portion (121) having at least one evaporator channel and a second portion (122) having at least one condenser channel. The base plate has a groove (111; 112) containing the tube element, wherein the groove is dimensioned for enabling thermal contact between the base plate and the first portion of the tube element and dimensioned to form a gap (113) between the base plate and the second portion of the tube element for thermal separation of the base plate and the second portion of the tube element.

Owner:ABB (SCHWEIZ) AG

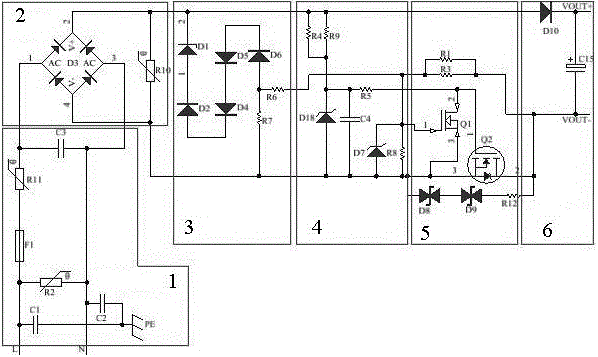

Circuit for realizing AC input voltage limiting by means of switch mode

ActiveCN105827105AFast switching speedIncrease the rated currentEfficient power electronics conversionEmergency power supply arrangementsComputer moduleEngineering

The invention discloses a circuit for realizing AC input voltage limiting by means of a switch mode. The circuit comprises an input circuit module, a rectifier circuit module, a comparison circuit module, a field effect transistor drive circuit module, a switch circuit module and an output circuit module, wherein the input circuit module inputs the AC input voltage, and outputs the AC input voltage to the comparison circuit module after rectification of the rectifier circuit module, and then eventually outputs the AC input voltage through the output circuit module; the field effect transistor drive circuit module and the switch circuit module are connected to a power supply loop between the comparison circuit module and an output end line module; the comparison circuit module is provided with a voltage comparison function by means of setting of a voltage-regulator tube; a voltage signal being less than a voltage comparison threshold value can switch on a load power supply loop; and a voltage signal being greater than the voltage comparison threshold value enables the comparison circuit module to output a switch-on signal so as to drive on / off of MOS switch tubes which are connected with an original power supply loop in serial and to disconnect the power supply loop. The circuit for realizing AC input voltage limiting by means of a switch mode has the advantages of being small in volume, being high in efficiency, being low in caloric power, and being very low in cost.

Owner:NR ELECTRIC CO LTD +1

Novel plate fuse and manufacturing method

ActiveCN1808667AHigh rated voltageIncrease the rated currentEmergency protective devicesCeramicVoltage

This invention relates to new type of safe fuse and its process method, which forms Monolithic structure by more than three layers of glass to ceramics layer and the metal film on each layer with two end prove on the conductive layer with inner metal film conducted. The method to process the fuse comprises the following steps: covering one layer of metal film on glass to ceramics layer; then covering one layer of ceramics layer and repeating the above steps to get the designed layer number to get the crude film slice of the monolithic structure; then cutting the film slice into single fuse to burst into ceramics and finally sealing and coating.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

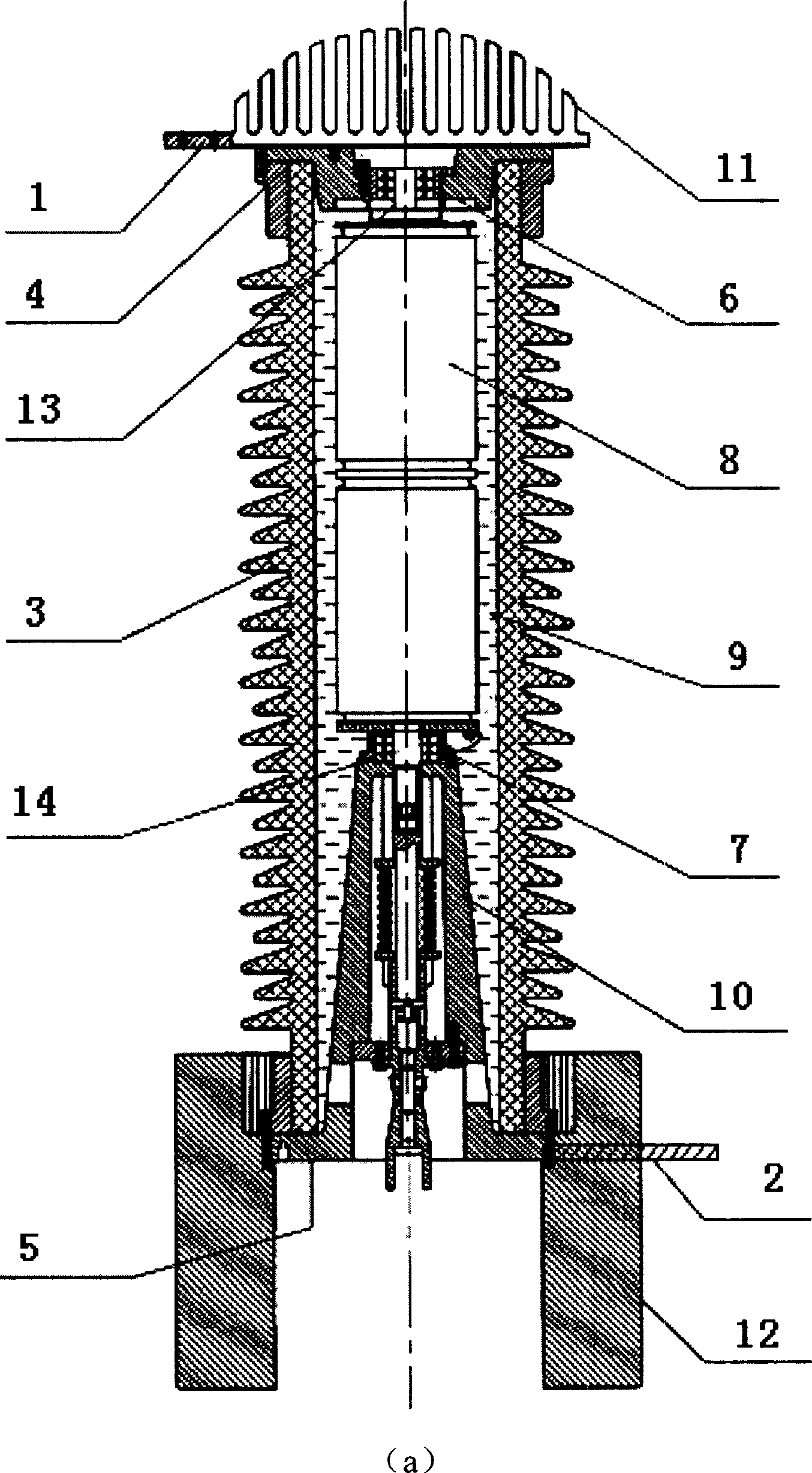

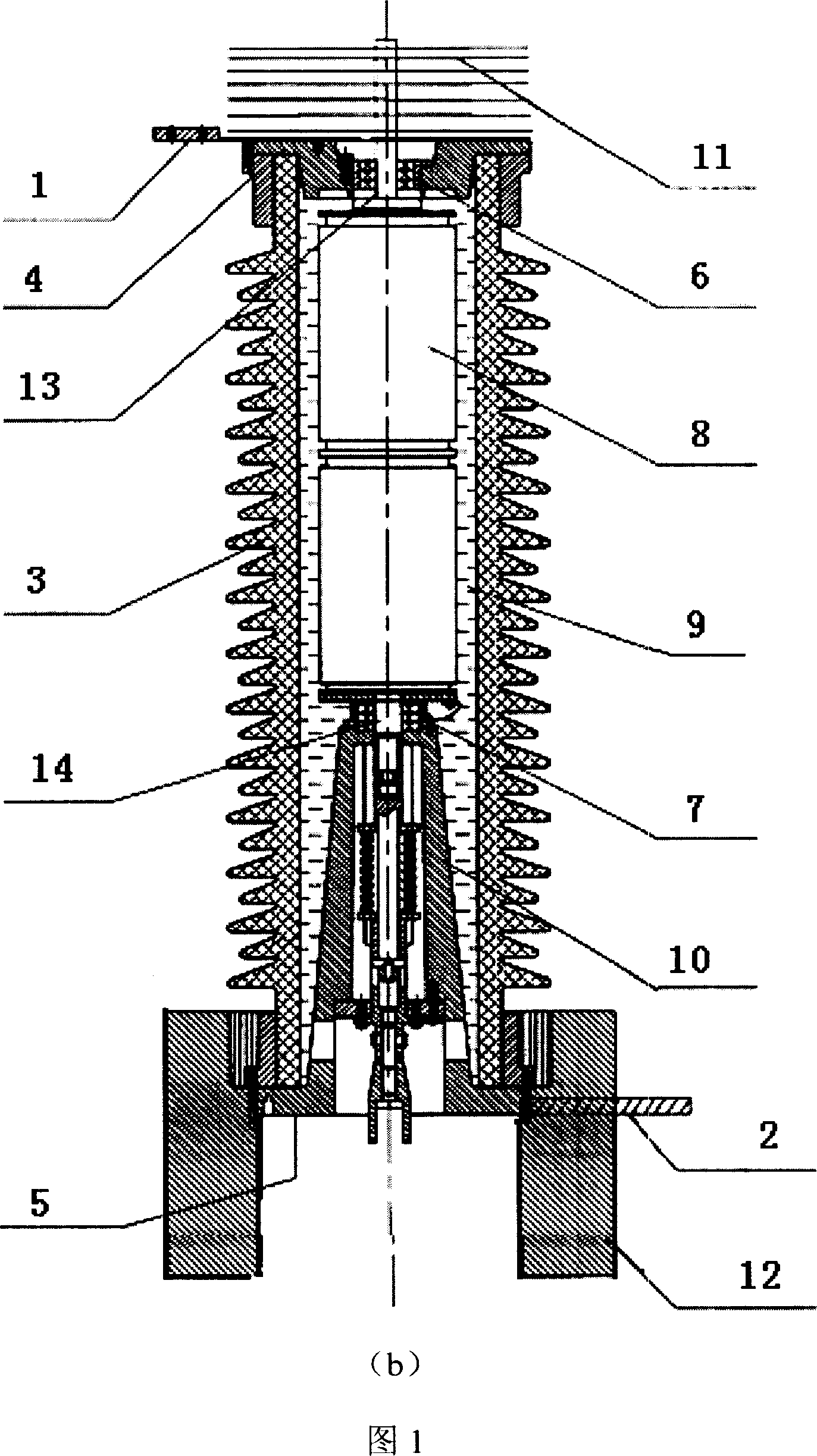

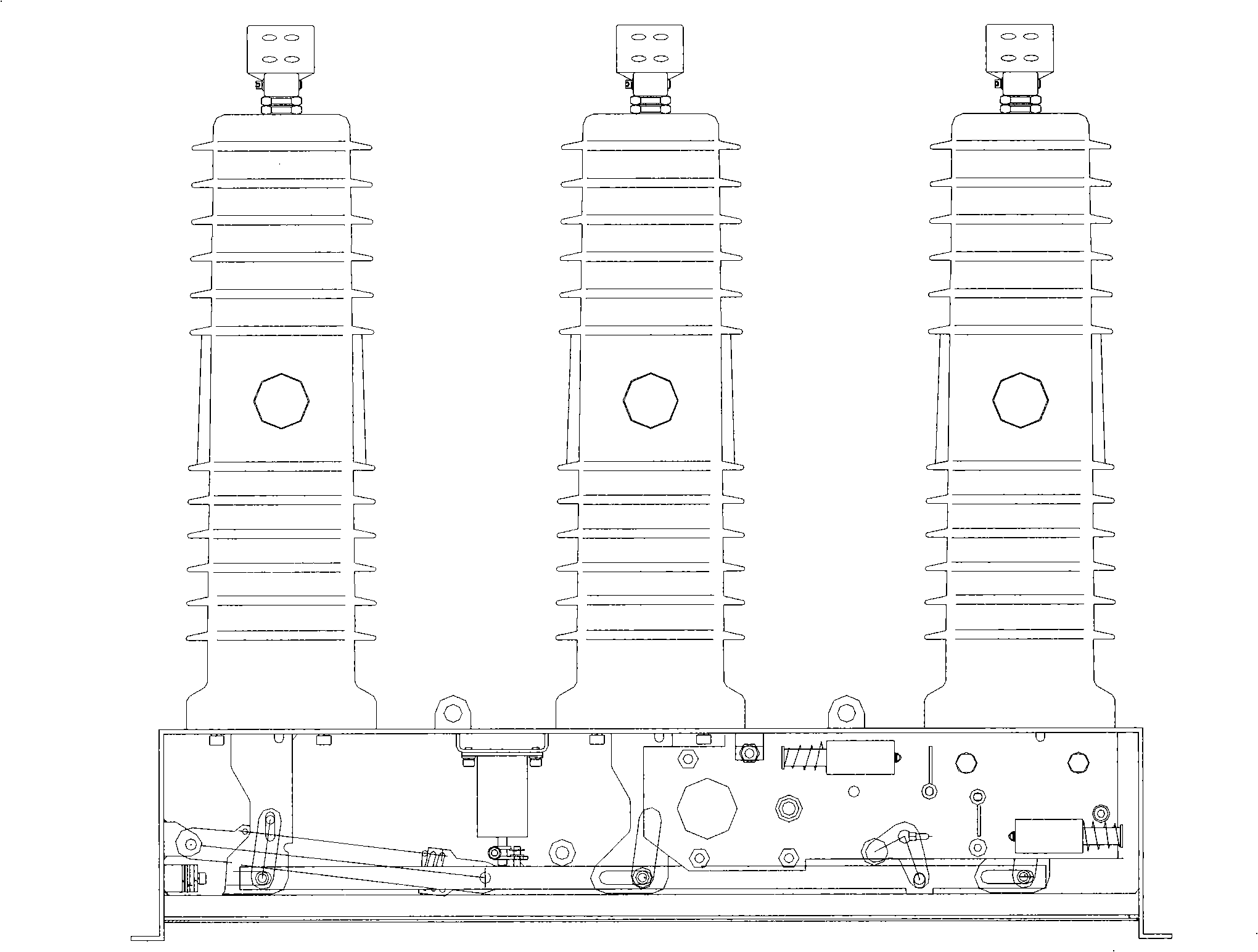

Vacuum circuit breaker on 24kV outdoor column

InactiveCN101345157AImprove insulation performanceIncrease the rated currentHigh-tension/heavy-dress switchesAir-break switchesMiniaturizationThree-phase

The invention provides a 24kV vacuum circuit breaker on an outdoor column; the whole structure of the vacuum circuit breaker adopts an open structure with separated three phases and eliminates the threatening of 'internal condensation'; the insulated structure adopts the composite insulation of epoxy resin and silicon rubber; furthermore, the insulation structure of the vacuum arc distinguish chamber is improved, and the insulation performance of the circuit breaker is improved; a miniaturized spring operation mechanism increase the switch-closing force of the spring operation mechanism simultaneously so as to sufficiently meet the switch-closing speed requirement of the 24kV outdoor circuit breaker; a special vacuum arc distinguish chamber is adopted so as to lead the rated current of the circuit breaker, the short circuit on / off current and the on / off time of the short circuit on / off current to be improved; the vacuum circuit breaker of the invention aims at the 24kV high-voltage power transporting circuit, fills up the blank of the similar equipment in China, and has the advantages of high reliability, miniaturization, intellectualization, maintenance-free, and strong on / off capability of short circuit current.

Owner:NANJING INTELLIGENT DISTRIBUTION AUTOMATION EQUIP

Laminate type magnetic ball

InactiveCN104051126AIncrease the rated currentIncrease the conductive areaFixed signal inductancesMagnetic beadDirect current

A laminate type magnetic ball comprises at least three layers of basal body diaphragms, end electrodes which are located on two sides of the basal body diaphragms and internal electrode coils which are arranged among different basal body diaphragms, wherein the internal electrode coils in different layers are same in structure, and wiring is realized in a parallel multipled mode. According to the laminate type magnetic ball, the rate current of the laminate type magnetic ball is greatly improved, and the direct current resistance is reduced at the same time.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Disk high-voltage direct-current generator

InactiveCN102738922ASimple structureExtensive sources of materialsMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

The invention relates to a disk high-voltage direct-current generator. The disk high-voltage direct-current generator consists of two parts, namely a stator and a rotor, wherein a power generating disk is combined by connecting the rotor with a connecting lead in series through a power generating unit, and a plurality of groups of power generating disks are superposed to form the generator rotor. The generator adopts the basic principle of Faraday disk power generation, the power generating unit is used for cutting magnetic induction lines of the vertical power generating disks to produce electromotive force, two adjacent power generating units are connected in series by virtue of the connecting lead, and the connecting lead cannot produce reverse electromotive force in rotation through magnetic shielding near the connecting lead to further enable the generator to have a very high power generating voltage. Meanwhile, the generator also can be used as a motor, and the generator and the motor with the structures have the characteristics of small internal resistance without iron loss, simple structure, wide material sources, large capacity, and small volume and calorific value. Used as the motor, the generator also has the advantages of great output torque and wide application range.

Owner:张学文

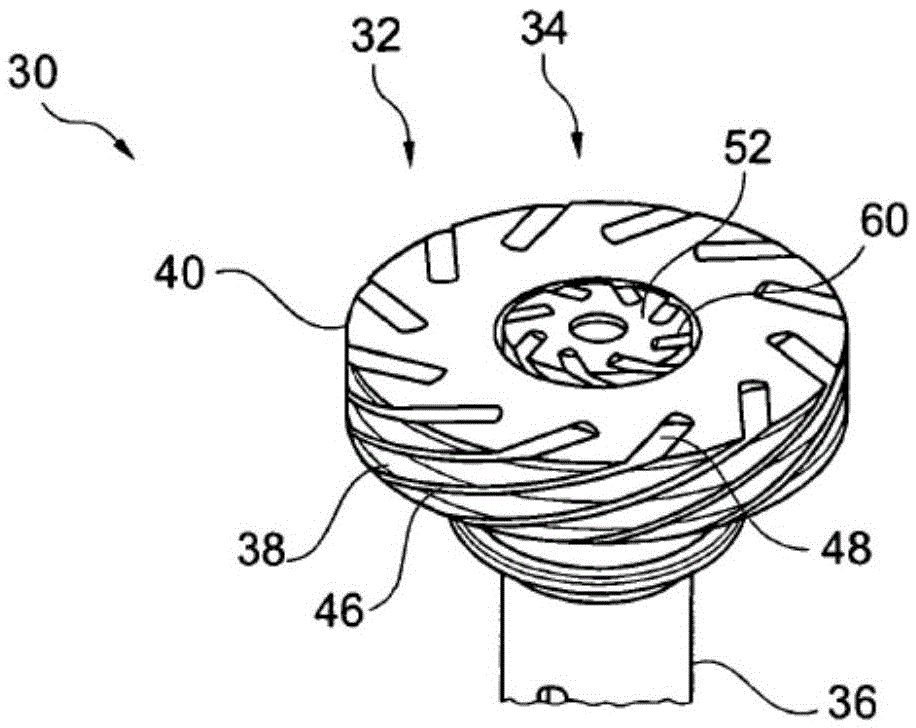

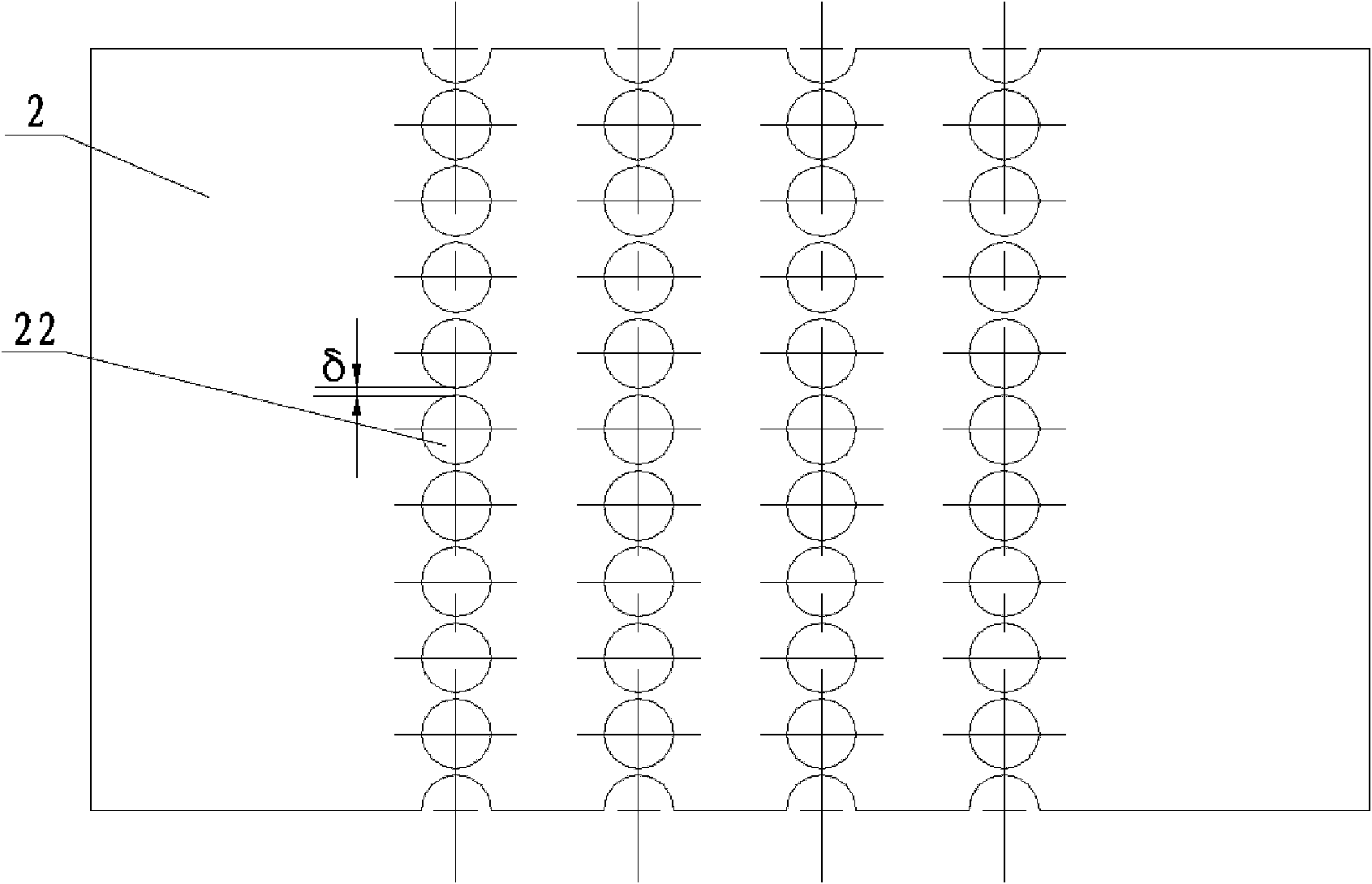

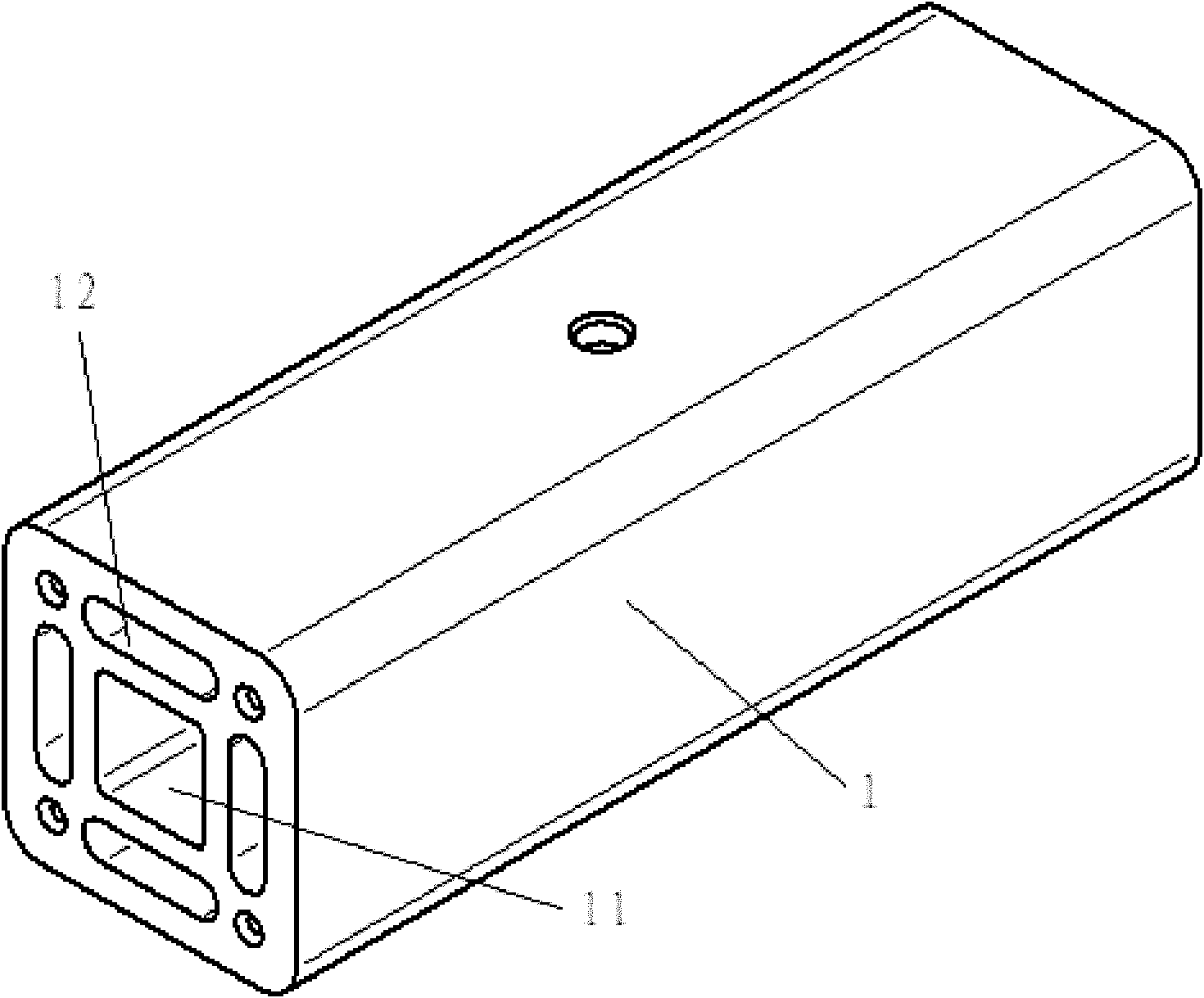

Inductor assembly and manufacturing method therefor

ActiveCN105719785AIncrease in sizeReduce volumeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectromagnetic interferenceInductor

The invention provides an inductor assembly. The inductor assembly is formed by multiple inductors in a packaging manner, wherein each inductor comprises an inductance coil and two E-shaped magnetic cores; each magnetic core comprises a bottom column, and a middle column and two side columns protruding from the bottom column to the same side; the bottom column, the middle column and the side columns jointly form a magnetic core plane; the two side columns are positioned on the two sides of the middle column respectively; the opening ends of the two magnetic cores face each other; the middle columns of the two magnetic cores face each other; the side columns of the two magnetic cores prop against each other; two magnetic cores form two magnetic loops; the inductance coils are wound around the middle columns of the corresponding two magnetic cores; an air gap is formed between the middle columns of the two magnetic cores; the inductors are tightly arranged on the magnetic core planes in a rectangular array manner; and the magnetic cores of every two adjacent inductors prop against each other. The invention also provides a manufacturing method for the inductor assembly. The external electromagnetic interference of the inductor assembly is greatly lowered; the space utilization rate is obviously improved; and the inductor assembly has a good magnetic shielding effect even if the inductor assembly is small in volume.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com