Novel permanent-magnet composite magnetic field contact structure and vacuum arc-extinguishing chamber employing same

A technology of vacuum interrupter and composite magnetic field, which is applied in high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of complex contact surface structure and limited arc control ability of permanent magnets, and achieve simple structure and low cost , The effect of simple contact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

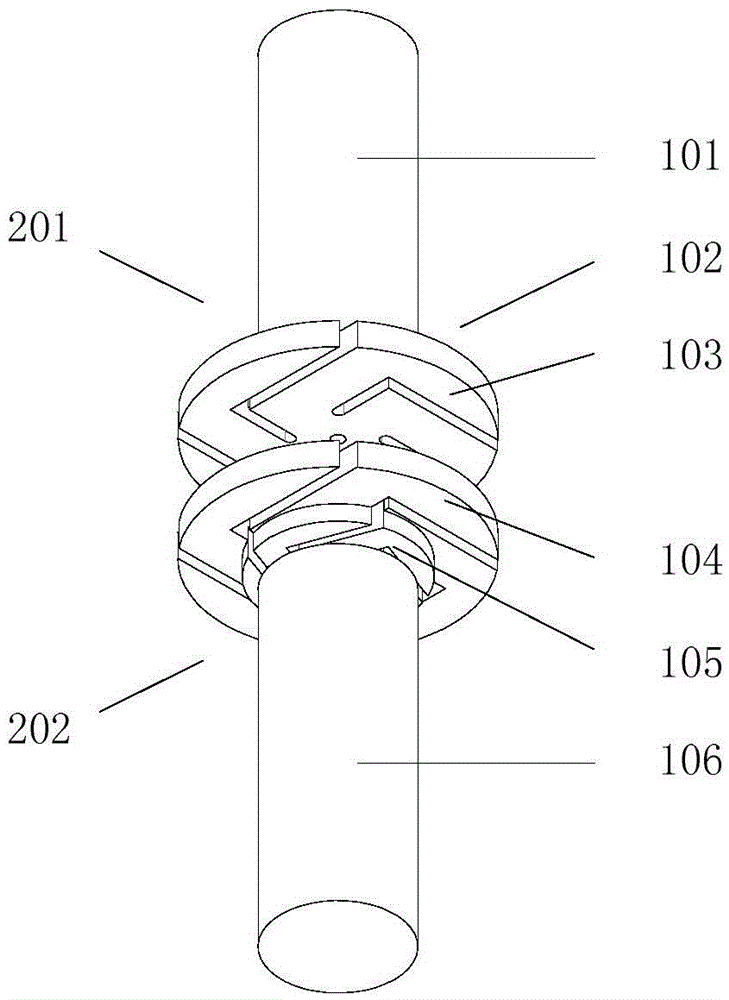

[0038] Figure 4 It is an axial sectional view of the permanent magnet compound magnetic field contact structure of the present invention. Such as Figure 4 As shown, the transverse magnetic field contact piece 105 at the stationary end and the transverse magnetic field contact piece 106 at the moving end have a “swastika” shaped transverse magnetic field contact structure. Behind the static end transverse magnetic field contact piece 105 and the moving end transverse magnetic field contact piece 106, the ends of the static end conductive rod 101 and the moving end conductive rod 110 are respectively welded with a static end permanent magnet combination structure 201 and a moving end permanent magnet combination structure 202. The static end permanent magnet combination structure 201 and the moving end permanent magnet combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com