Quick fuse for protection of semiconductor devices

A semiconductor and fuse link technology, applied in emergency protection devices, electrical components, circuits, etc., can solve the problems of complex manufacturing process, large space occupation, unfavorable heat dissipation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

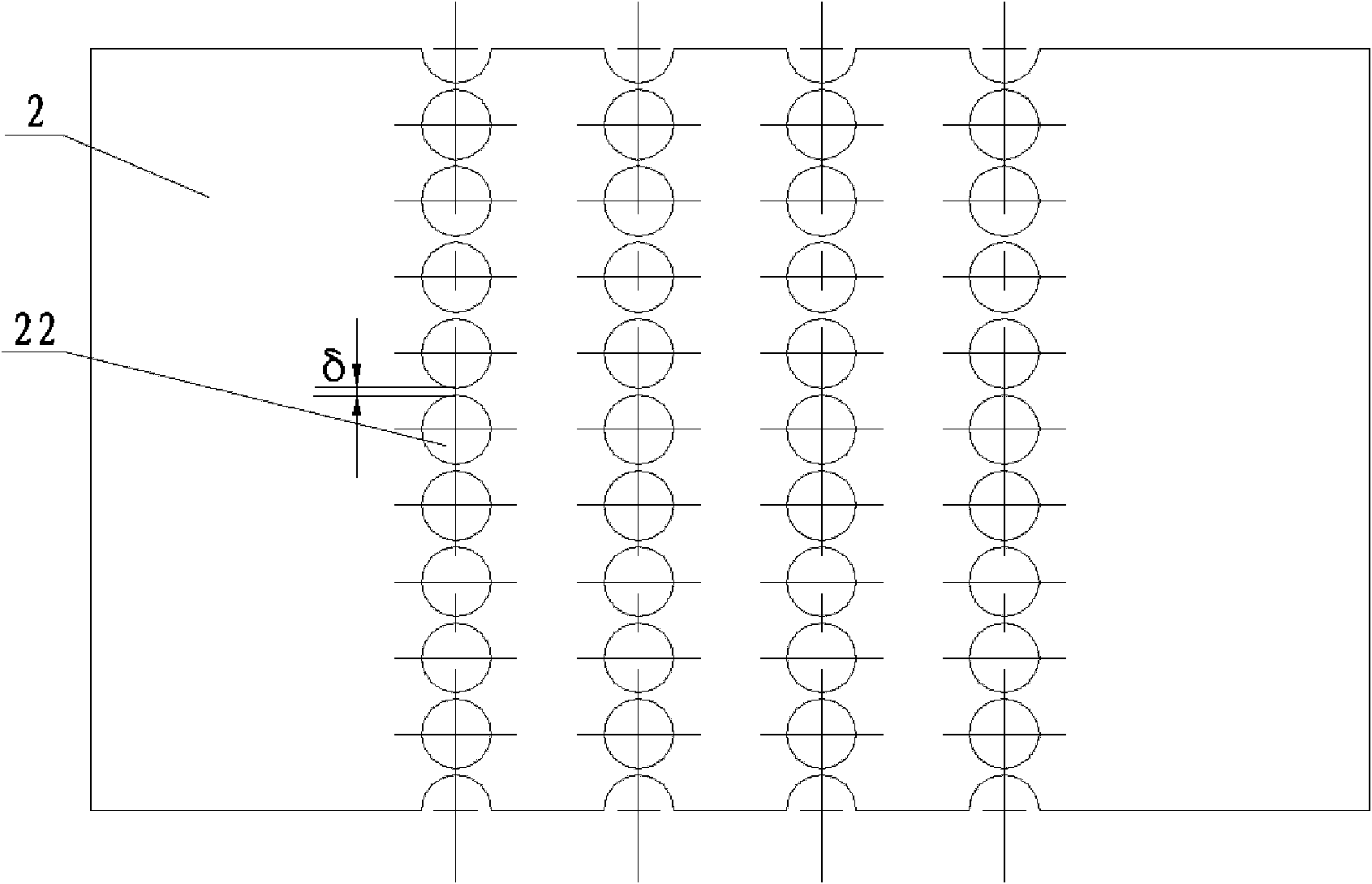

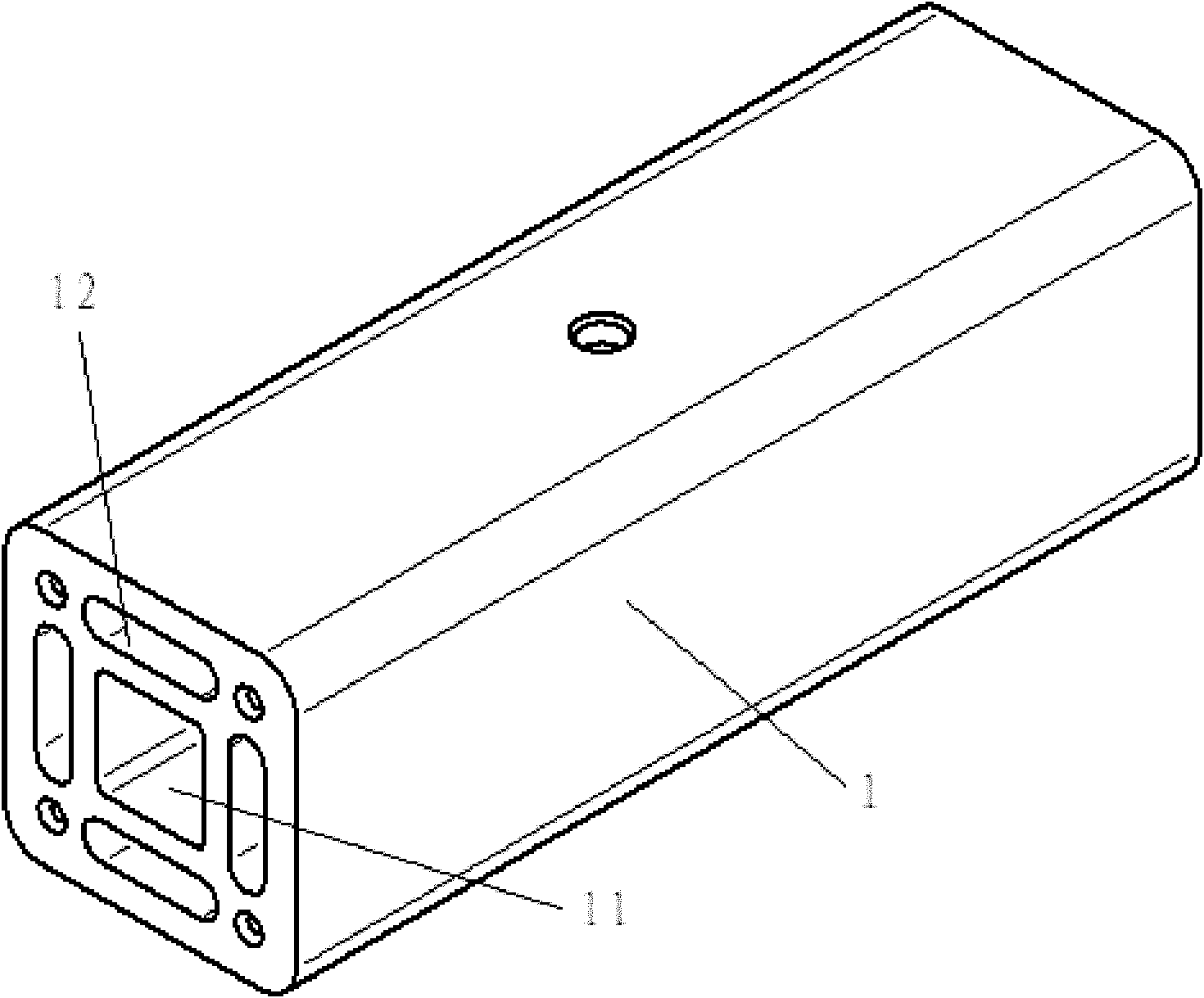

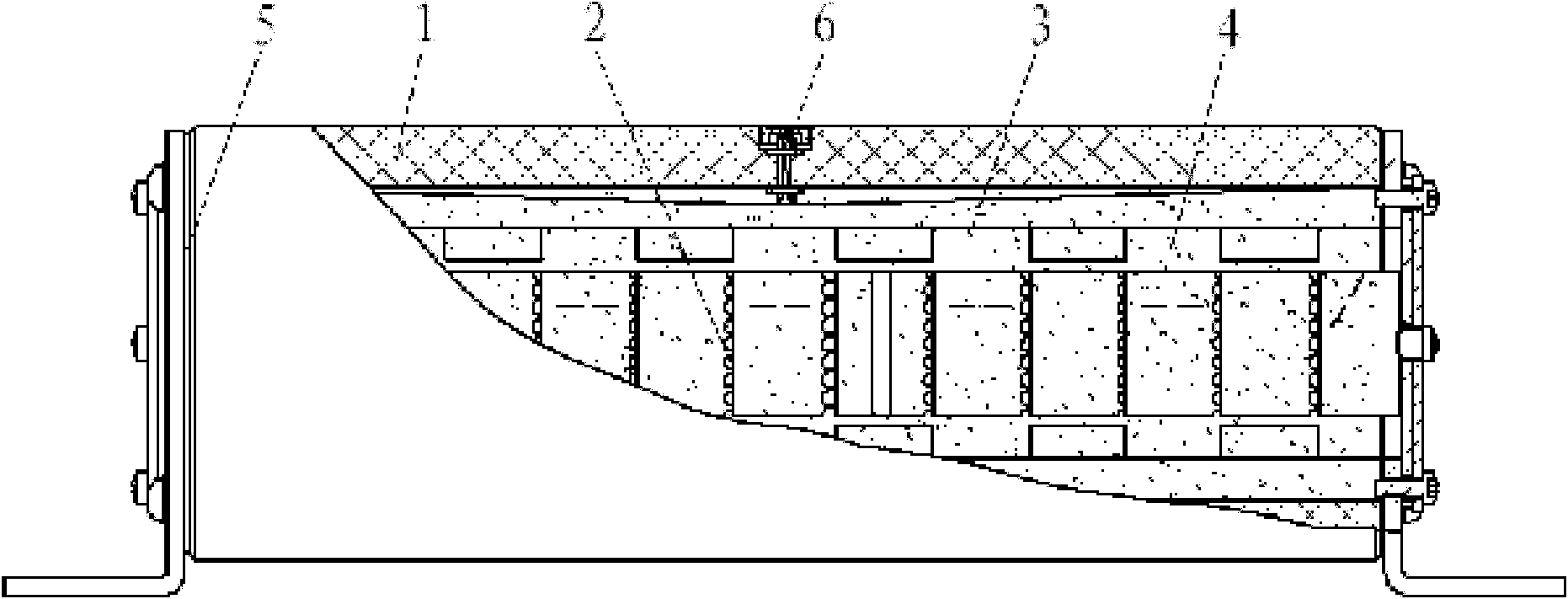

[0031] see Figure 2 to Figure 7 , the semiconductor device protection fast fuse of the present invention includes a melting tube 1, four melts 2, an arc extinguishing medium 4, a pair of contact plates 5 and an indicator 6, wherein:

[0032] The outer surface of the melting tube 1 is a regular square prism, which is made of No. 95 alumina ceramic insulating material, which has good high temperature resistance and mechanical properties, and is also more beautiful in appearance; the center of the end face of the melting tube 1 has a cavity with a regular quadrilateral cross section. 10. The cavity 10 is used not only as an installation cavity for the melt 2, but also as a cooling cavity; a radial perforation connecting the cavity 10 is provided on the wall of the melting tube 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com