Fuse

A technology of fuses and fuses, which is applied in the manufacture of electrical components, circuits, and fuses, and can solve problems such as shortening of distances, deterioration of fusing characteristics, and reduction of fusing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

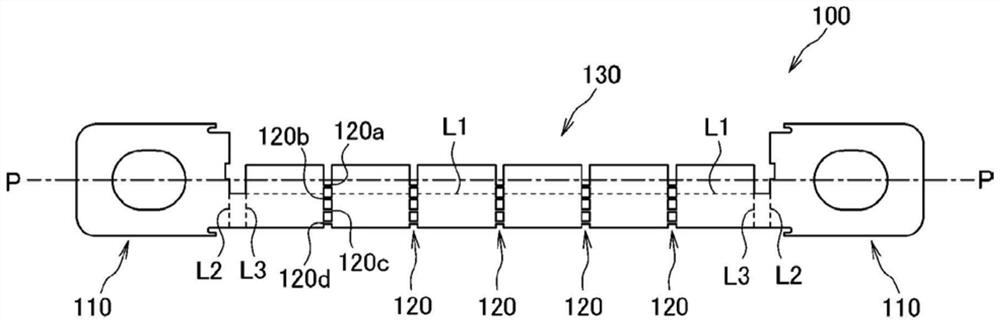

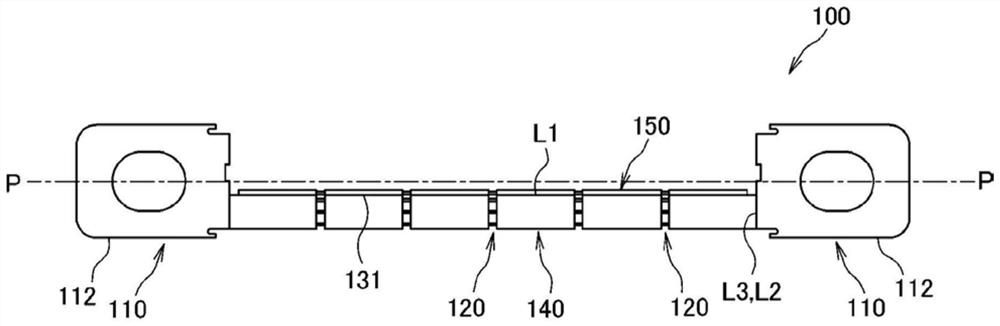

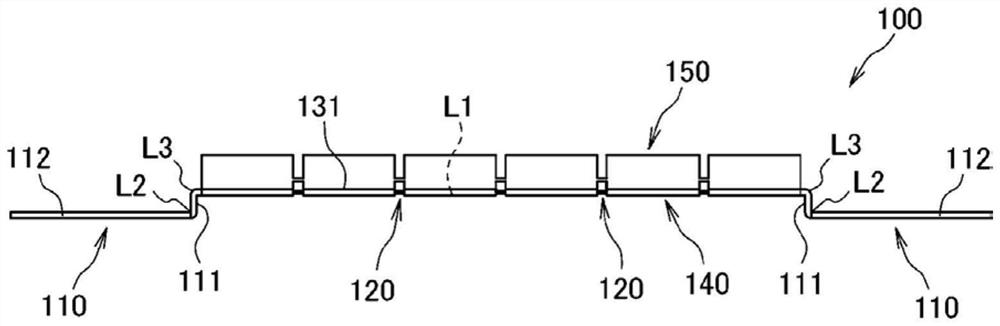

[0042] Fig. 1 shows a manufacturing process of a fuse element 100 of a fuse according to a first embodiment of the present invention. Note that Fig. 1(a) is a plan view of the unfolded state of the fuse element 100; Fig. 1(b) is a plan view of the state in which the fuse element 100 is bent; Fig. 1(c) is a front view of the fuse element 100 in said state; Figure 1(d) is a side view of the fuse element 100 in that state; and figure 2 is an overall perspective view of the fuse element 100 .

[0043] First, a flat plate of uniform thickness formed of a conductive metal such as copper or copper alloy is punched into the shape shown in FIG. 1( a ) using a press or the like. As shown in FIG. 1( a ), a metal plate made in a predetermined shape is formed with terminal parts 110 at both ends, a flat intermediate part 130 between the terminal parts 110 , and a plurality of fuse parts 120 . Specifically, the fuse part 120 is composed of a fuse part 120a, a fuse part 120b, a fuse part 1...

no. 2 approach

[0071] A fuse 600A according to a second embodiment of the present invention will be described below with reference to FIGS. 6 to 8 . Note that the specific configuration of the fuse 600A is common to the fuse 600 according to the first embodiment, and thus a detailed description of the common configuration is omitted.

[0072] First, FIG. 6 shows a manufacturing process of a fuse element 100A of a fuse 600A according to a second embodiment of the present invention. Note that Fig. 6 (a) is a perspective view of the unfolded state of the fuse element 100A; Fig. 6 (b) is a perspective view of the state of the fuse element 100A being bent; Overall perspective.

[0073] First, a flat plate of uniform thickness formed of a conductive metal such as copper or copper alloy is punched into the shape shown in FIG. 6( a ) using a press or the like. A metal plate having a predetermined shape as shown in FIG. 6( a ) includes terminal portions 110A at both ends, a flat intermediate portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com