Melt for DC fuse link

A fuse and melt technology, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of poor cut-off performance, slow fusing speed, long fuse time, etc., and achieve stable fusing characteristics, fast fusing speed, and work Effect of temperature rise and heat dissipation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

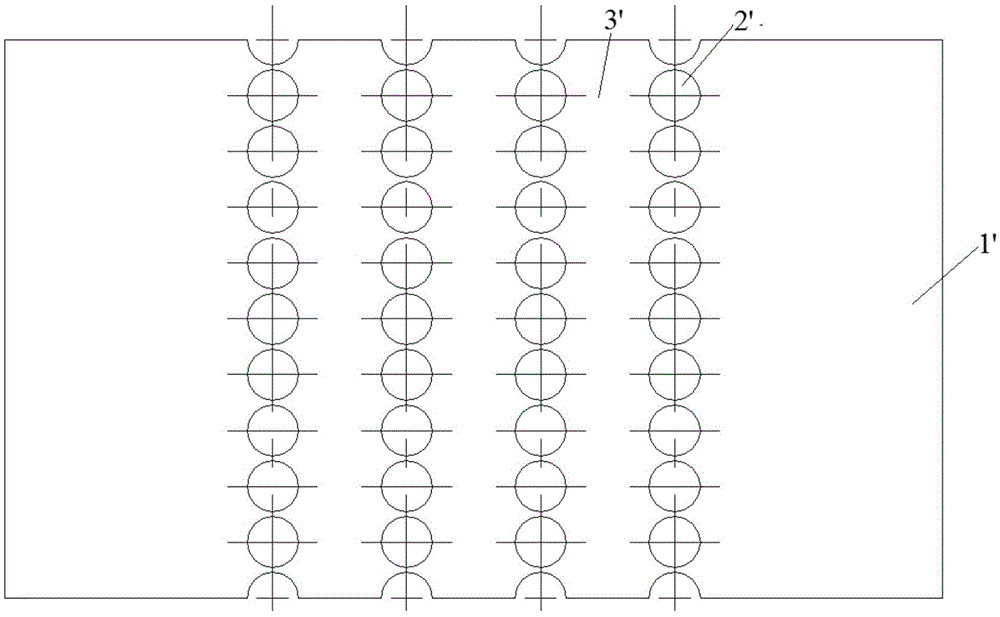

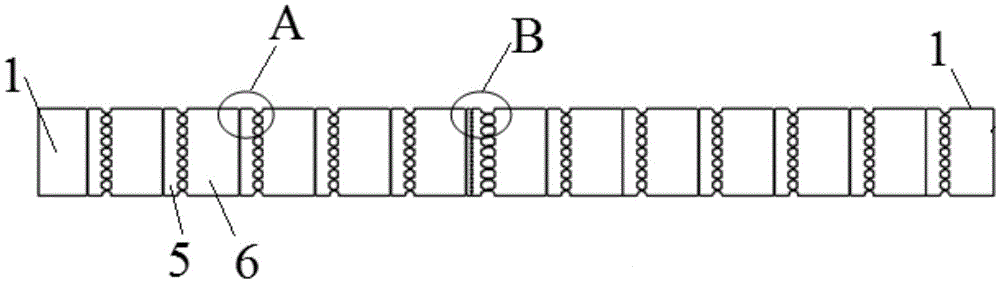

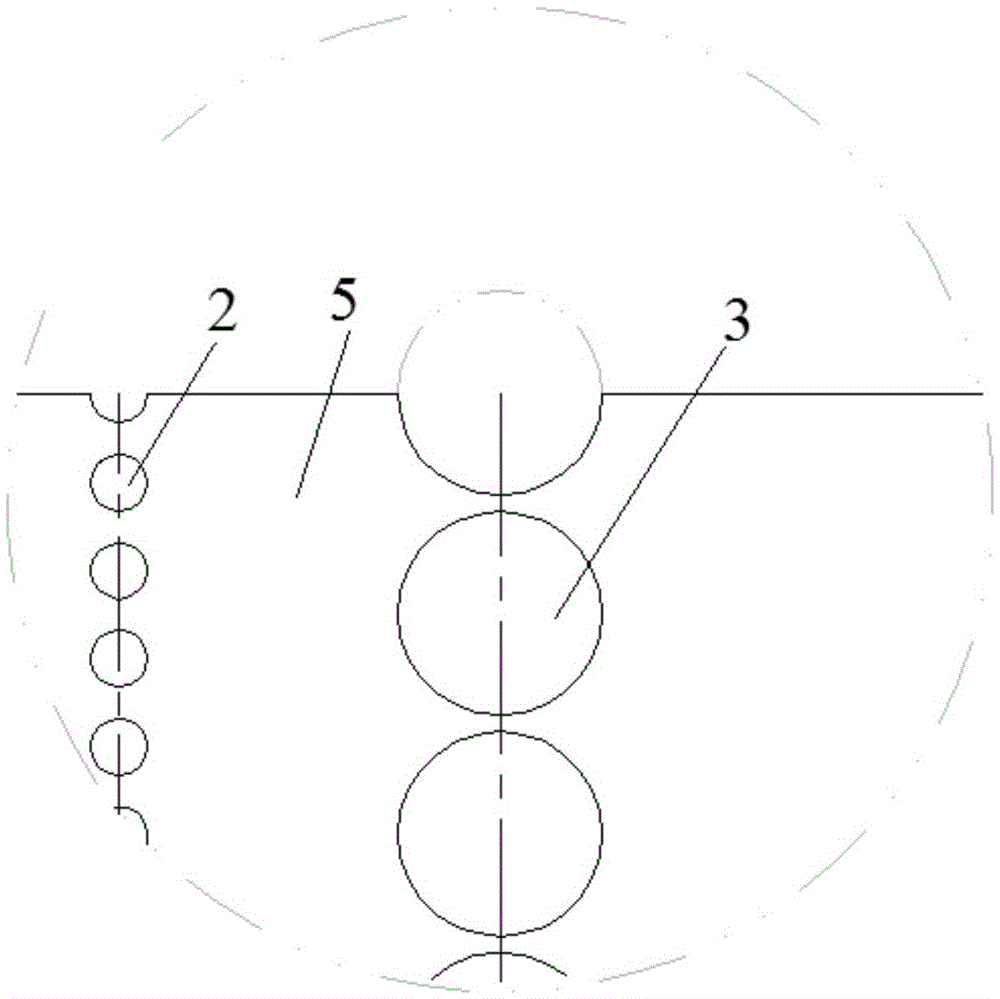

[0024] see figure 2 , image 3 and Figure 4 , the best embodiment of the present invention, a melt for DC fuses, comprising two melt bodies 1, each melt body 1 is provided with a series of first holes 2 and a series of second holes 3, The size of the first hole 2 is smaller than the size of the second hole 3, the first hole 2 is circular, the second hole 3 is circular, and the aperture of the first hole 2 is smaller than the aperture of the second hole 3; The second hole 3 of the series is distributed on the corresponding melt body 1 at intervals from left to right; the two melt bodies 1 are connected in a partially overlapping manner, and the overlap of the two melt bodies 1 is distributed from left to right. There is a row of first holes 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com