Hot Melt Release Coil System

A heat-melting technology to release springs and coils, which is applied in the field of medical devices, can solve the problems of long separation time, unfixed coils, uneven welding parts, etc., and achieve short operation time, less pain for patients, and fast fusing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

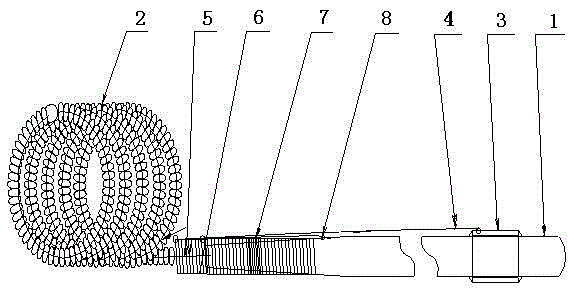

[0020] Embodiment 1: as attached figure 1 As shown, a heat-melting decoil system includes a coil 2, a conveying steel wire 1, two enamelled wool threads 4, 8, unequal diameter springs 6, return electrodes 3 and medical polymer fibers 5, and a conveying steel wire 1 The front portion is provided with a marking ring 7. The unequal diameter spring 6 of the present invention is formed by connecting arc lines of different diameters, and the centers of each arc line are not on the same straight line. The unequal diameter spring 6 The diameter of the circular arc line is 0.05-0.3 mm, the rear end of the unequal spring 6 is fixedly connected with the marking ring 7, the rear end of the conveying steel wire 1 is fixedly sleeved with a return electrode 3, and the side is provided with two enamelled wool wires 4, 8, the front end of an enamelled wool wire 4 is fixedly connected to the front end of the unequal diameter spring 6, the rear end is fixedly connected to the return electrode 3,...

Embodiment 2

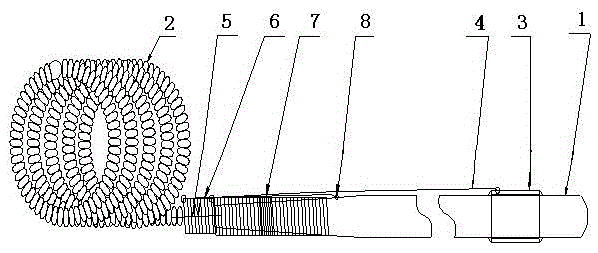

[0021] Embodiment 2: as attached figure 2 As shown, a heat-melting decoil system includes a coil 2, a conveying steel wire 1, two enamelled wool threads 4, 8, unequal diameter springs 6, return electrodes 3 and medical polymer fibers 5, and a conveying steel wire 1 The front portion is provided with a marking ring 7. The unequal diameter spring 6 of the present invention is formed by connecting arc lines of different diameters, and the centers of each arc line are not on the same straight line. The unequal diameter spring 6 The diameter of the circular arc line is 0.03-0.1 mm, the rear end of the unequal spring 6 is fixedly connected with the marking ring 7, the rear end of the conveying steel wire 1 is fixedly sleeved with a return electrode 3, and the side is provided with two enamelled wool wires 4, 8, the front end of an enamelled wool wire is fixedly connected to the front end of the unequal diameter spring, the rear end is fixedly connected to the return electrode, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com