Fusing current adjustable fuse

A technology for fusing current and fuses, applied in circuits, electrical components, emergency protection devices, etc., can solve the problems of slow fusing response of fuses, and achieve the effect of fast fusing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

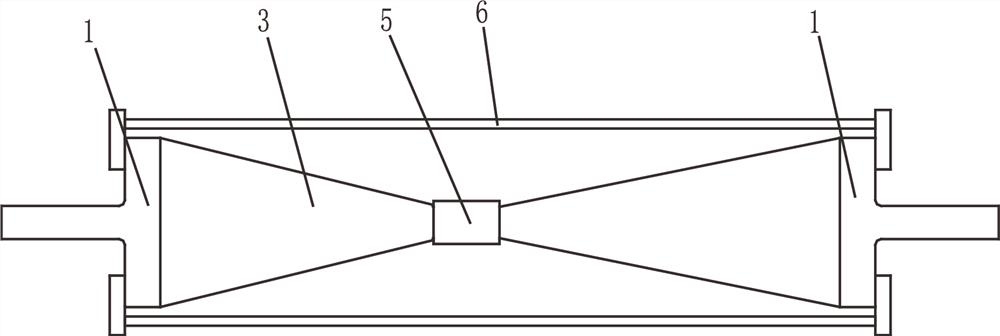

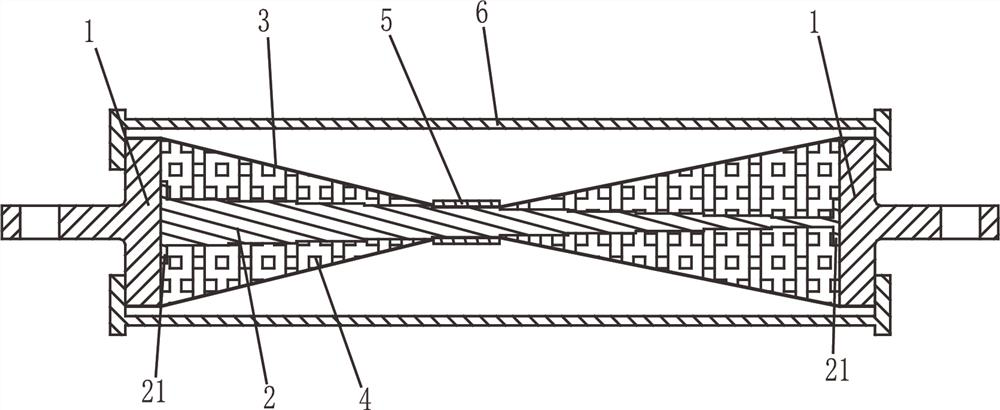

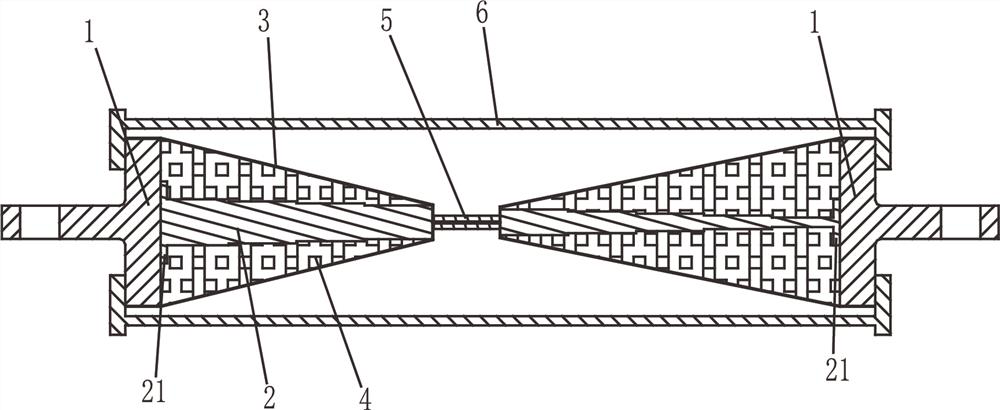

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , a fuse with adjustable fusing current, including conductive connectors 1 at both ends, and a fuse 2 between the conductive connectors 1, the fuse 2 is made of commonly used fuse materials, such as copper, Materials such as silver, zinc, lead, and lead-tin alloy can be used. The outer side of the fuse body 2 is provided with an insulating elastic sleeve 3, and the insulating elastic sleeve 3 is filled with a conductive medium 4. The radius of the fuse body 2 gradually increases from one end to the other end. An elastic partition 5 is arranged on the outer periphery of the elastic sleeve 3 , and the elastic partition 5 separates a section of the fuse 2 from the conductive medium 4 on the outer periphery of the insulating elastic sleeve 3 and isolates the conductive medium 4 on both sides. When this kind of fuse with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com