Belt Drive Clamping Shoe Cover Machine

A technology of belt drive and shoe cover machine, which is applied in the direction of clothing, applications, hangers, etc., can solve the problems of inconsistent clamping force between the upper and lower sides, the appearance of the upper and lower parts, and the peeling off of the formed shoe film, and achieve the effect of fast melting speed and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

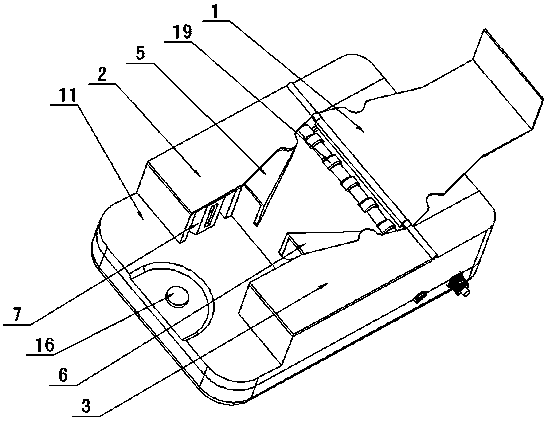

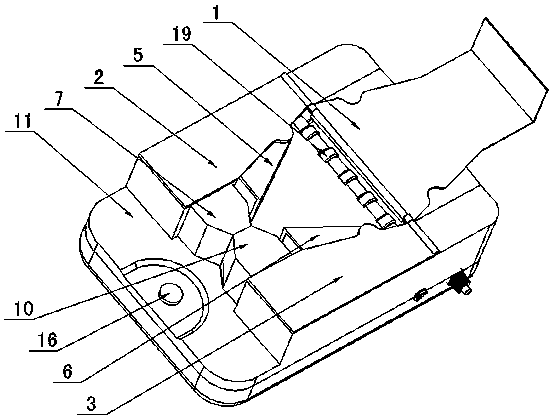

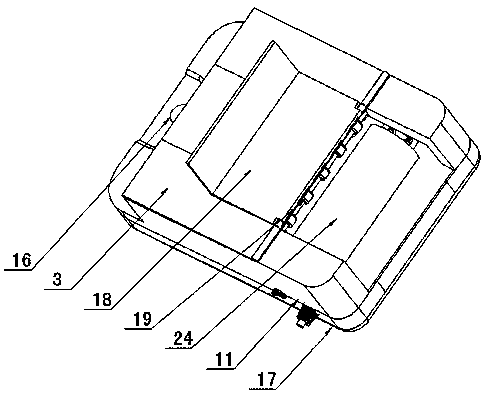

[0020] Figure 1 to Figure 5 Shown, for the present invention creates and adopts the concrete embodiment of the belt drive clamping shoe cover machine of electrothermal heating, it comprises base 17, middle cover 11, left and right movable plates 5,6, shoe film cylinder 24, shoe film conveying roller 19, Controller 23, shoe film clamping device, described shoe film clamping device comprises left and right clamping seats 7,10, clamping motor 13, double-ended screw rod 14, belt 15, and left and right clamping seats 7,10 are correspondingly arranged on On the left and right sliding seats 12 of the middle cover 11, the clamping motor 13 is fixed on the base 17, and the double-ended screw 14 is rotatably arranged on the base 17. The clamping motor 13 drives the double-ended screw 14 to rotate through the belt 15, and the left and right clamping Seats 7 and 10 are arranged on the double-ended screw rod 14 so as to be movable relative to each other through screw fit, and shoe film fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com