Mould-locking linkage recycled aggregate self-conserving heat plate

A technology of recycled aggregates and thermal insulation plates, applied in thermal insulation, building components, sustainable waste treatment, etc., can solve the problem of lack of high value-added utilization technology of construction waste, unsatisfactory external thermal insulation durability, poor thermal performance of internal thermal insulation, etc. problem, to solve the problem of wall cracks, high construction efficiency, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 , Prepare mold card interlocking recycled aggregate self-insulation plate components

[0049] According to the formula shown in Table 1, measure the components of the self-insulating plate in proportion, add water according to the water-cement ratio of 0.3-0.55, and stir in the mixer to mix the components evenly for later use.

[0050] Table 1

[0051]

Embodiment 2

[0052] Example 2 , Manufacture of mold card chain recycled aggregate self-insulation plate

[0053] Follow the steps below to prepare the mold card interlocking recycled aggregate self-insulation board:

[0054] A. Measure each component of the insulation plate shown in Table 1 of Example 1 in proportion, add water according to the water-cement ratio 0.3-0.55, and mix and stir evenly;

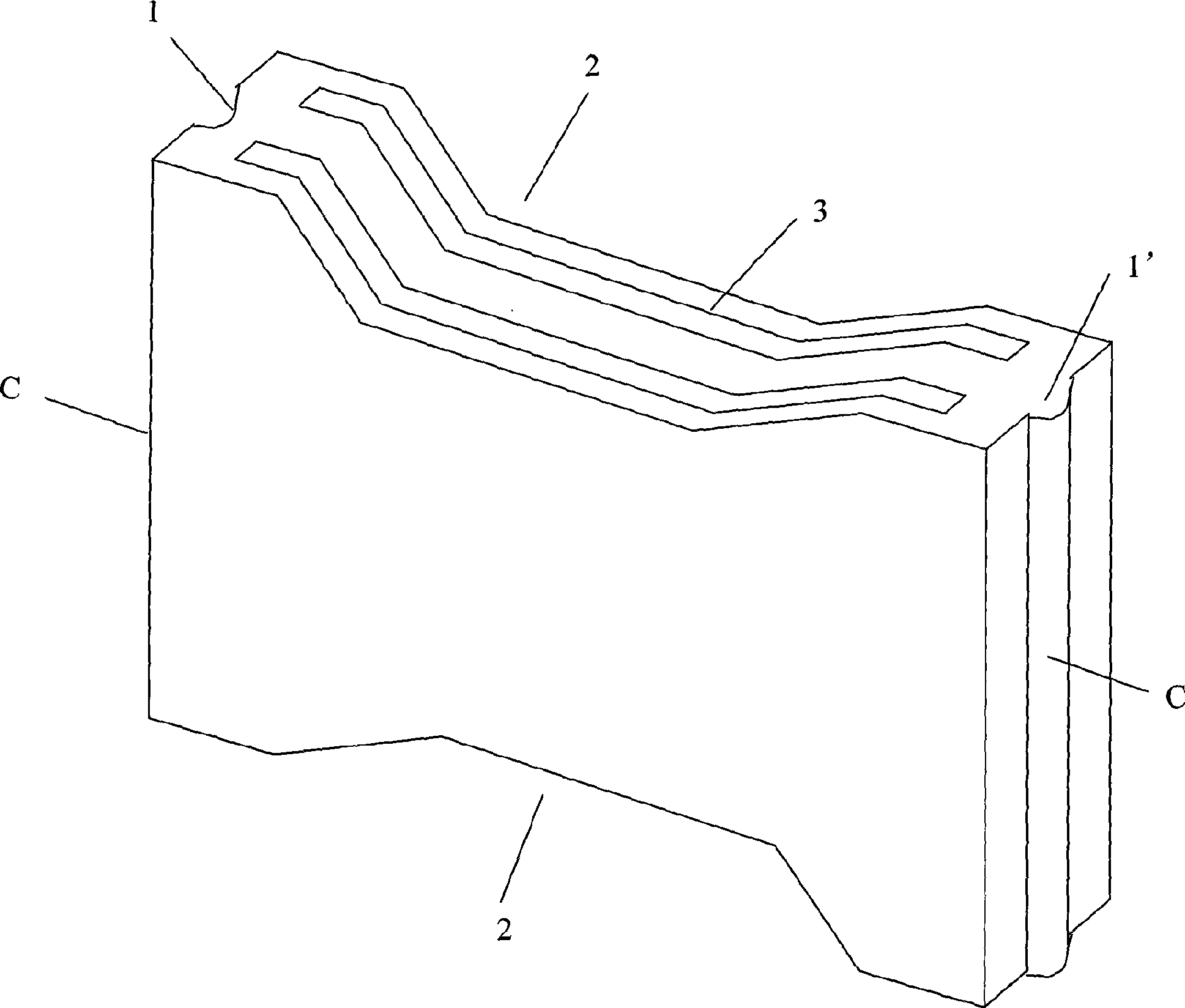

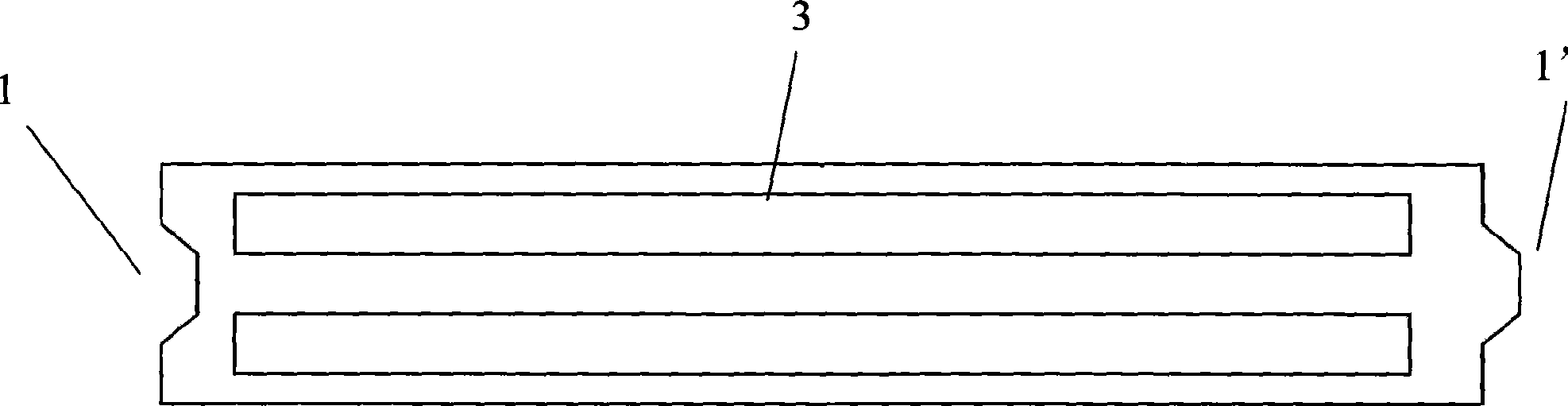

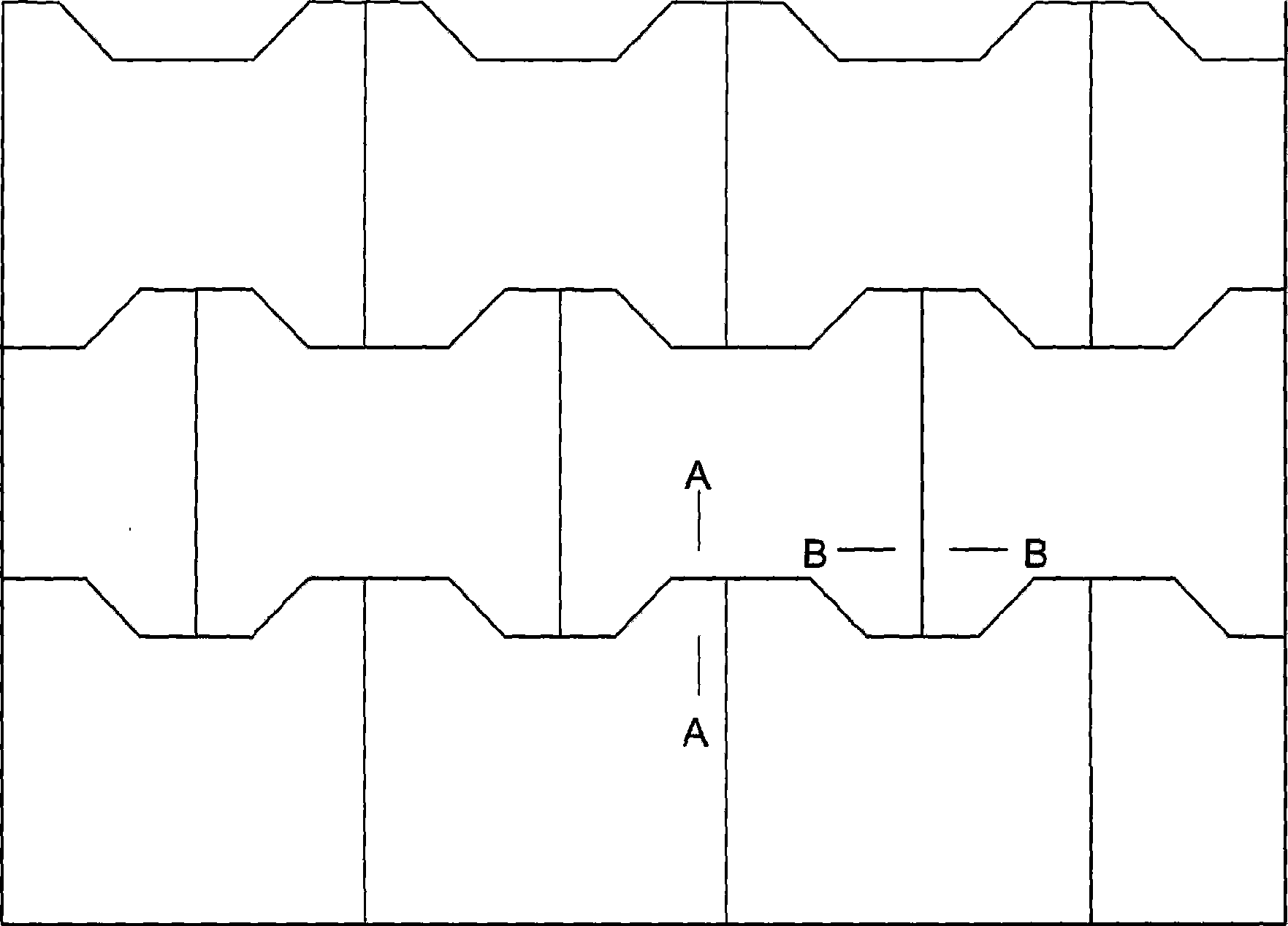

[0055] B. The preset formwork support frame, there are concave-convex tongue and groove positions on both sides of the support, and the upper and lower sides of the support are respectively in the shape of shape, leaving a double row of holes in the middle;

[0056] C, pouring each component of the homogeneously mixed insulation plate;

[0057] D. Vibrating mandrel molding or ordinary mold casting;

[0058] E, demoulding;

[0059] F. Inject thermal insulation material into the double row of holes;

[0060] G. Natural conservation.

[0061] According to the above method, there are three s...

Embodiment 3

[0066] Example 3 , The performance of the self-insulation plate of mold card interlocking recycled aggregate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com