Side pole novel forming technology and mould

A molding process, a new type of technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven wing surface, distortion of forming workpieces, poor forming process of side columns, etc., and achieve beautiful appearance, high forming precision, and convenient Effects of clearance adjustment and assembly maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

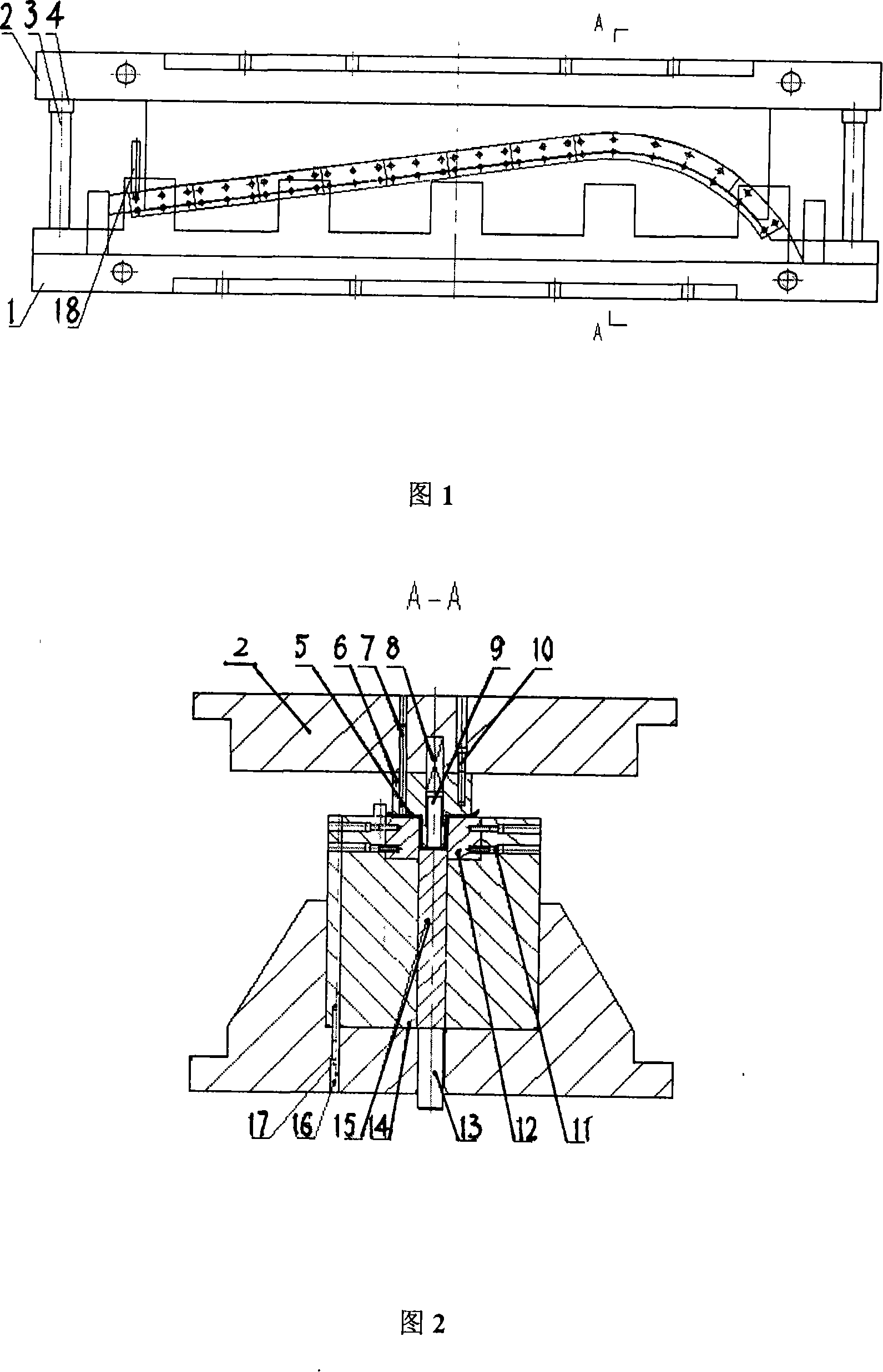

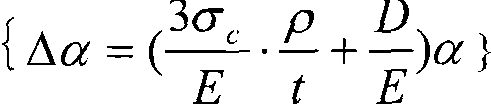

[0013] According to Fig. 1 and Fig. 2, the mold of the present invention consists of an upper template 2 and a lower template 1 to form a box-type composite structure. Both the upper template 2 and the lower template 1 are processed with grooves, and are connected to the upper slider of the press through the pressing plate during work. , provide a power transmission platform for the upper formwork 2, and provide a static force-bearing platform for the lower formwork 1. Joint guidance is adopted between the upper and lower molds, and the guide sleeve 4 and the guide post 3 provide guidance when the mold is working.

[0014] Among them, the bottom of the upper template 2 is provided with a forming punch 6 and a jacking pin 9, the jacking pin 9 is limited by a shoulder, and a return spring 8 is installed between the jacking pin and the upper template 2, for the ejector pin to move from the top to the top after forming. The ejection part 5 on the punch provides elastic force. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com