Plastic modular component

A modular and component technology, applied in the field of visible body panels and modular components of vehicles, can solve problems such as limited heating efficiency and achieve reliable protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

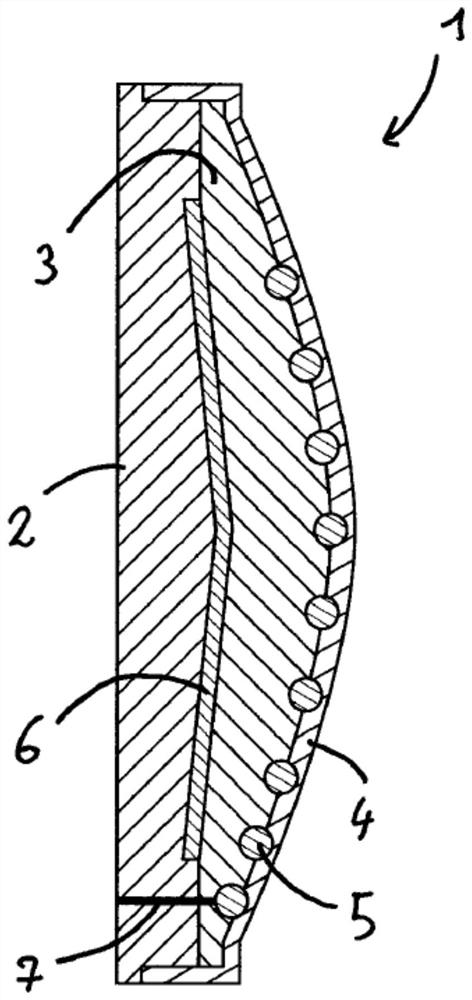

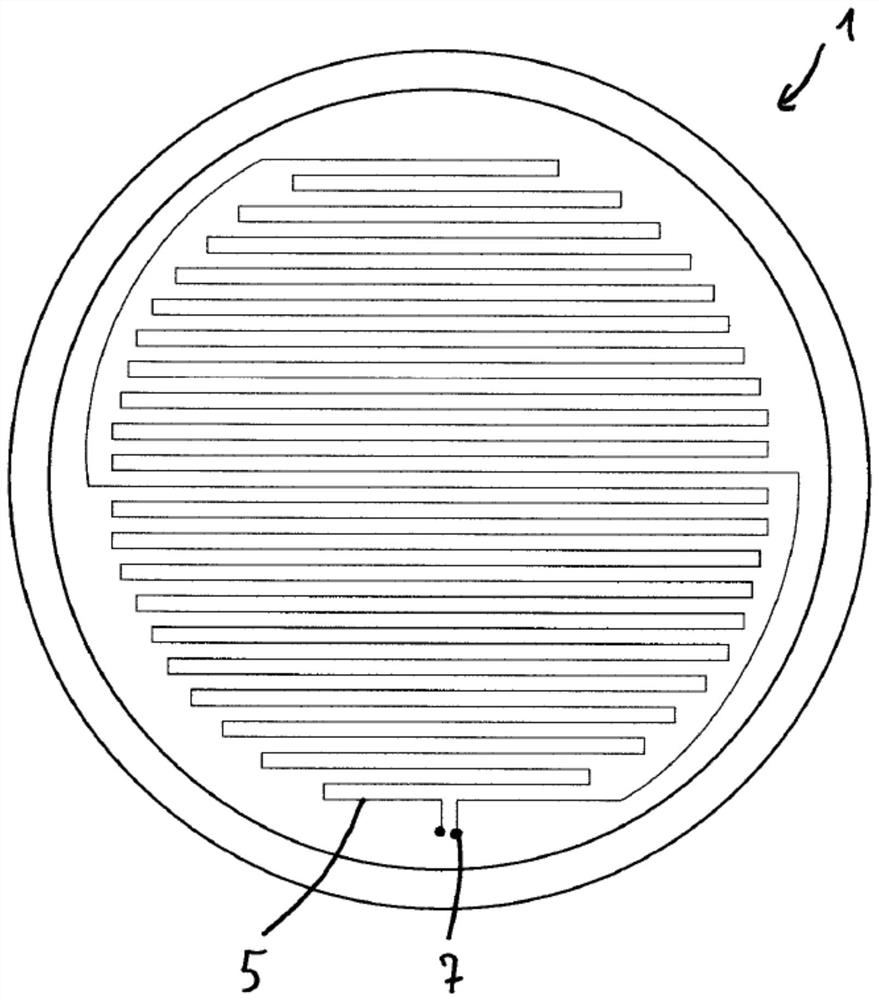

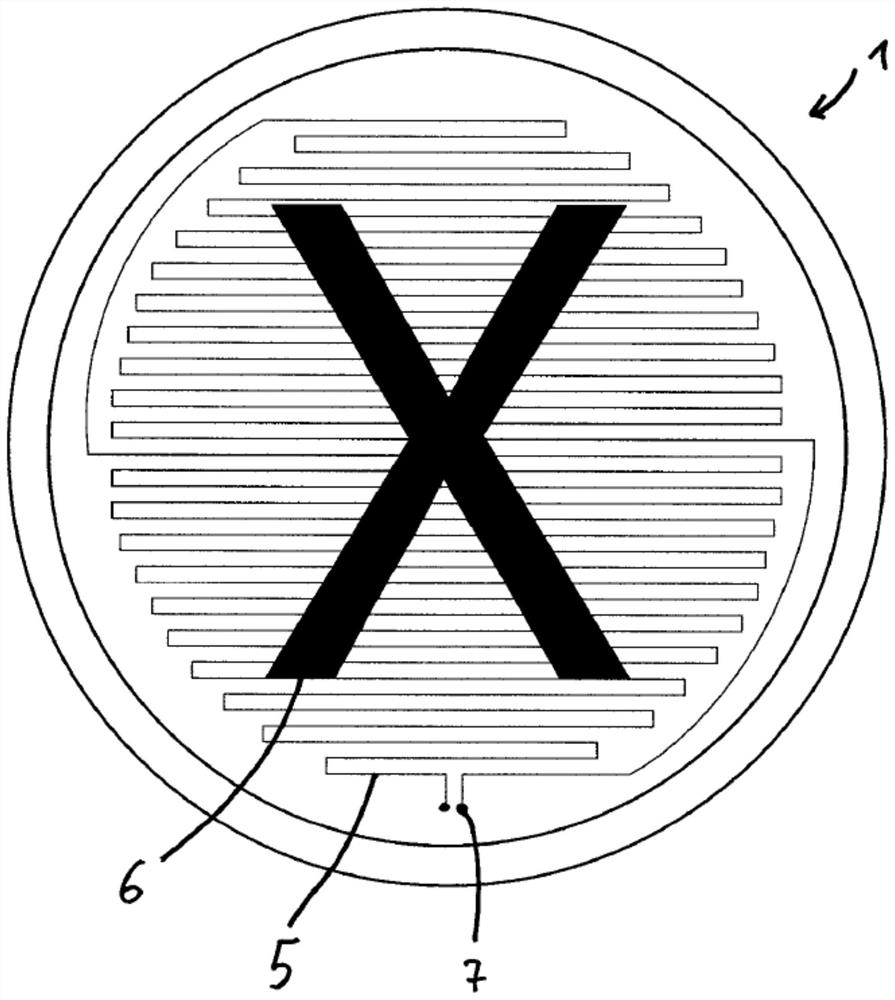

[0038] figure 1 A schematic sectional view of a modular component 1 made of plastic according to a first embodiment of the invention is shown. A modular component 1 made of plastic according to the invention comprises a component body 2 , which is preferably transparent to a radar system, and at least one first 3 and one second 4 plastic layer. In order to enable the modular component according to the invention made of plastic to be heated, a heating wire 5 is at least partially arranged between the first plastic layer 3 and the second plastic layer 4 . In order to additionally set optical decoration, in the present invention figure 1 In the embodiment shown, a decorative or functional layer 6 is at least partially arranged between the component body 2 and the first plastic layer 3 . In the present example, this layer is preferably transparent to the radar system, for example made of colored polycarbonate. In particular, it can also be a material arranged in film form.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com