Secondary gas protection device for narrow-gap MAG/MIG automatic welding

A gas protection device and automatic welding technology, which is applied in the direction of welding protection devices, welding equipment, welding accessories, etc., can solve the problems of reduced protection effect, unfavorable reduction of welding production costs, and increase of production costs, so as to reduce operation and maintenance costs, The effect of eliminating welding porosity defects and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

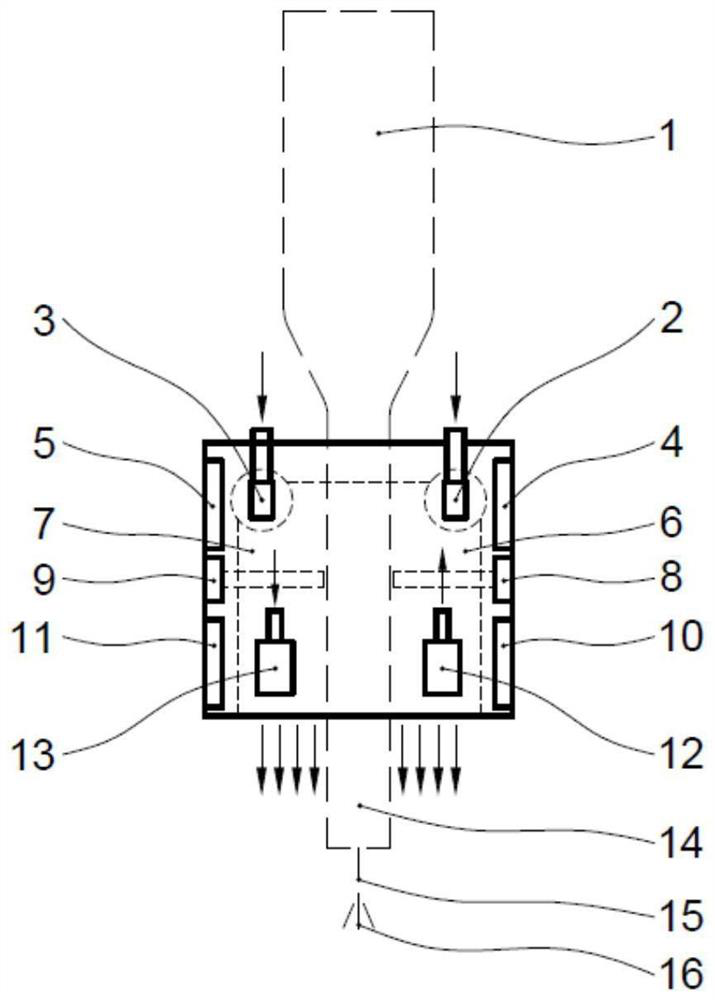

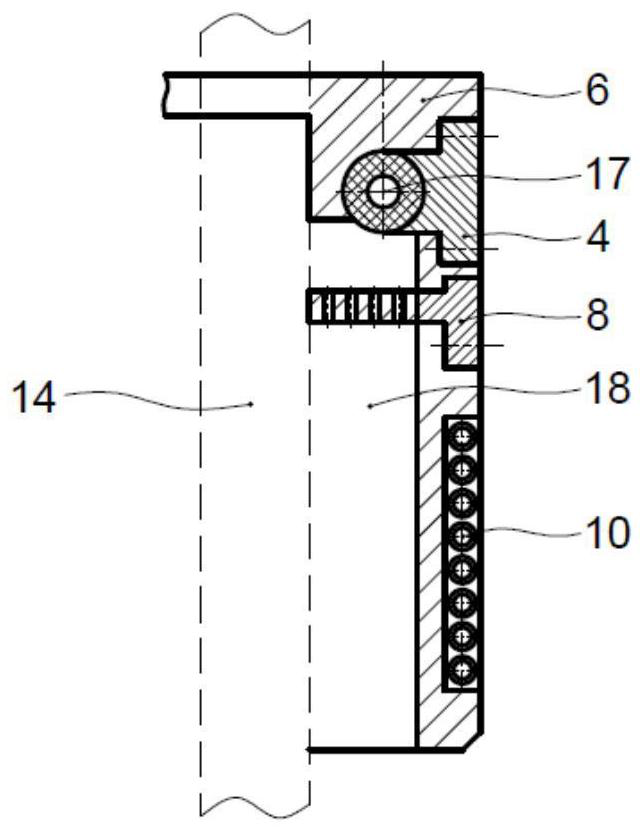

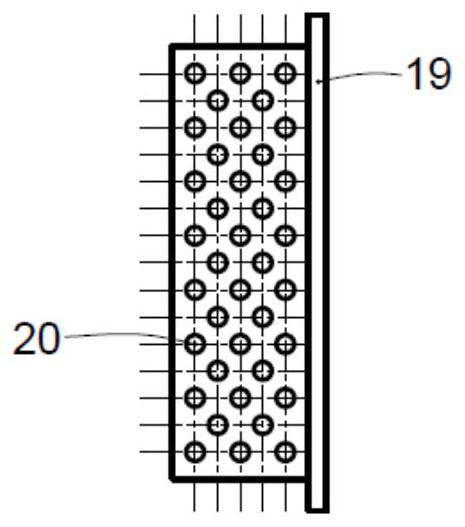

[0026] like Figure 1-7 As shown, a long-life narrow-gap MAG / MIG automatic welding secondary gas protection device mainly includes: a front device body 6, a rear device body 7, a screen pipe 17, a front screen pipe protection structure 8, and a rear screen pipe protection Structure 9 , front restrictor guide groove 18 , rear restrictor guide groove 25 , front circulating water cooling structure 10 and rear circulating water cooling structure 11 .

[0027] The front device body 6 and the rear device body 7 are two rectangular cuboid structures that are mirror images of each other. The upper part of each rectangular cuboid structure is provided with the installation structure of the uniform flow filter screen tube 17, the middle part is provided with the protection structure of the filter screen tube, the lower part is provided with the flow restriction guide groove, and the outer part of the lower current restriction guide groove is strongly irradiated by light and heat. Equip...

Embodiment 2

[0034] A secondary gas protection device under the condition of narrow gap MAG / MIG welding, the filter tube 17 has an outer diameter of 11mm and an inner hole diameter of 6mm; the front restrictor guide groove 18 and the rear front restrictor guide groove 25 are 40mm long and 10mm wide. The height is 46 mm; both the front filter screen tube protection structure 8 and the rear filter screen tube protection structure 9 have 106 equalizing holes 20 with a diameter of 1 mm. Other structures are the same as in Example 1.

Embodiment 3

[0036] A secondary gas protection device under the condition of narrow gap MAG / MIG welding, the front circulating water cooling structure 10 and the rear circulating water cooling structure 11 are respectively machined with semicircular grooves in the lower part of the front device body 6 and the rear device body 7 by ball milling, Another semicircle of equal diameter is machined on the milling hole cover plate 21, and then welded by brazing. Other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com