Liquid direct contact type cooling device

A cooler and contact technology, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of large contact thermal resistance, liquid leakage, and inability to dissipate heat from high-power devices, so as to improve heat dissipation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

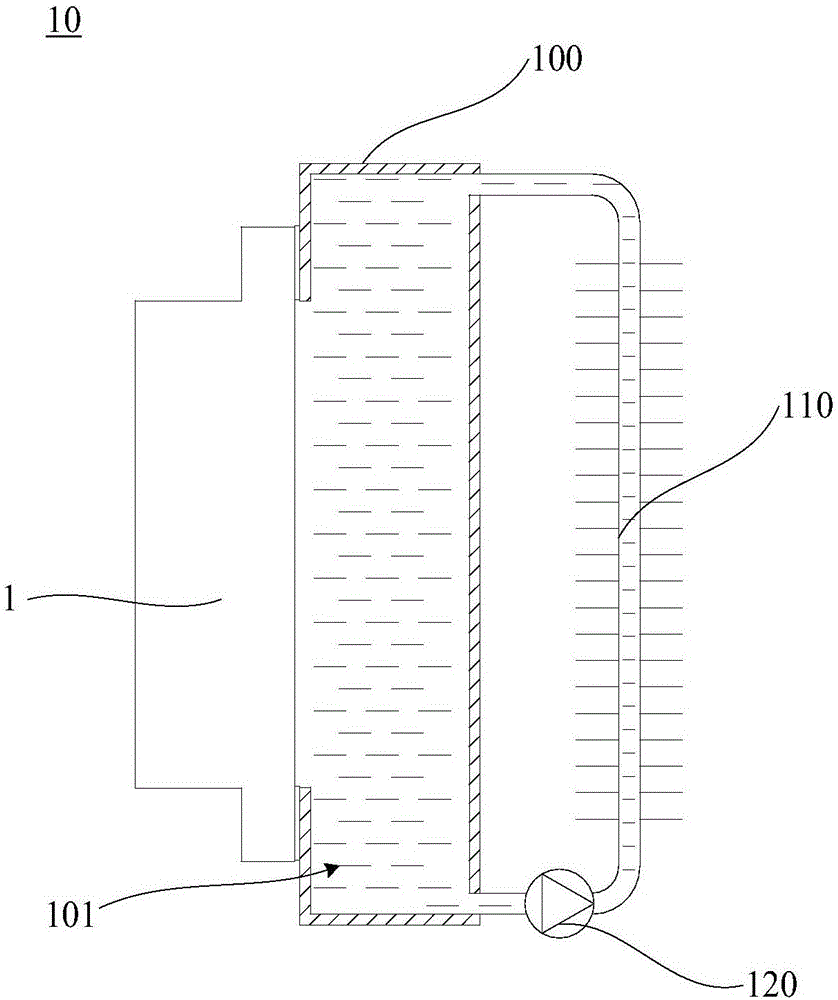

[0037] Please refer to figure 1 , this embodiment provides a liquid immersion cooler 10 for heat dissipation of a power device 1 , including a cooler body 100 , a heat exchange structure 110 and a circulation pump 120 .

[0038] The cooler body 100 has a cooling cavity 101 and a cooling port communicating with the cooling cavity 101 . The heat dissipation opening is disposed at a middle portion of a side wall of the cooler body 100 . The cooling cavity 101 is used for filling the insulating and heat-conducting liquid, and for making the insulating and heat-conducting liquid directly contact the heat-dissipating surface of the power device through the heat dissipation opening. The cooler body 100 at least surrounds the peripheral portion of the heat dissipation opening and is sealingly fitted with the heat dissipation wall through an insulating sealant layer.

[0039] The liquid inlet of the heat exchange structure 110 is connected with the liquid outlet of the cooler body 100,...

Embodiment 2

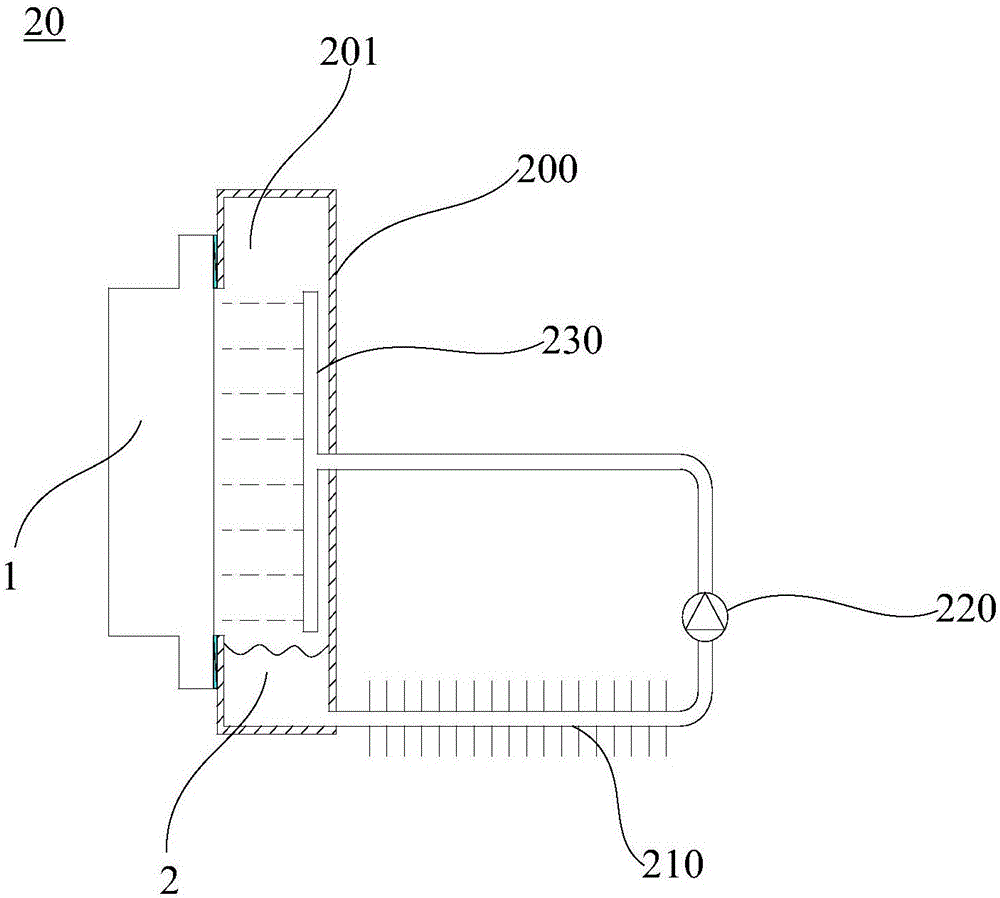

[0043] Please refer to figure 2 , this embodiment provides a liquid spray cooler 20 for heat dissipation of the power device 1 , including a cooler body 200 , a heat exchange structure 210 , a circulation pump 220 and a spray structure 230 .

[0044] The cooler body 200 has a cooling cavity 201 and a cooling port communicating with the cooling cavity 201 . The heat dissipation opening is arranged in the middle of a side wall of the cooler body 200, and the cooler body 200 at least surrounds the peripheral portion of the heat dissipation opening for sealing fit with the heat dissipation wall through an insulating sealant layer. The cooling channel of the heat exchange structure 210 communicates with the cooling cavity 201 through a return pipe. The heat exchange structure 210 exchanges heat through water cooling. The circulation pump 220 is arranged on the return pipeline, and is used to make the cooling medium 2 flowing out of the cooling cavity 201 flow back into the cooli...

Embodiment 3

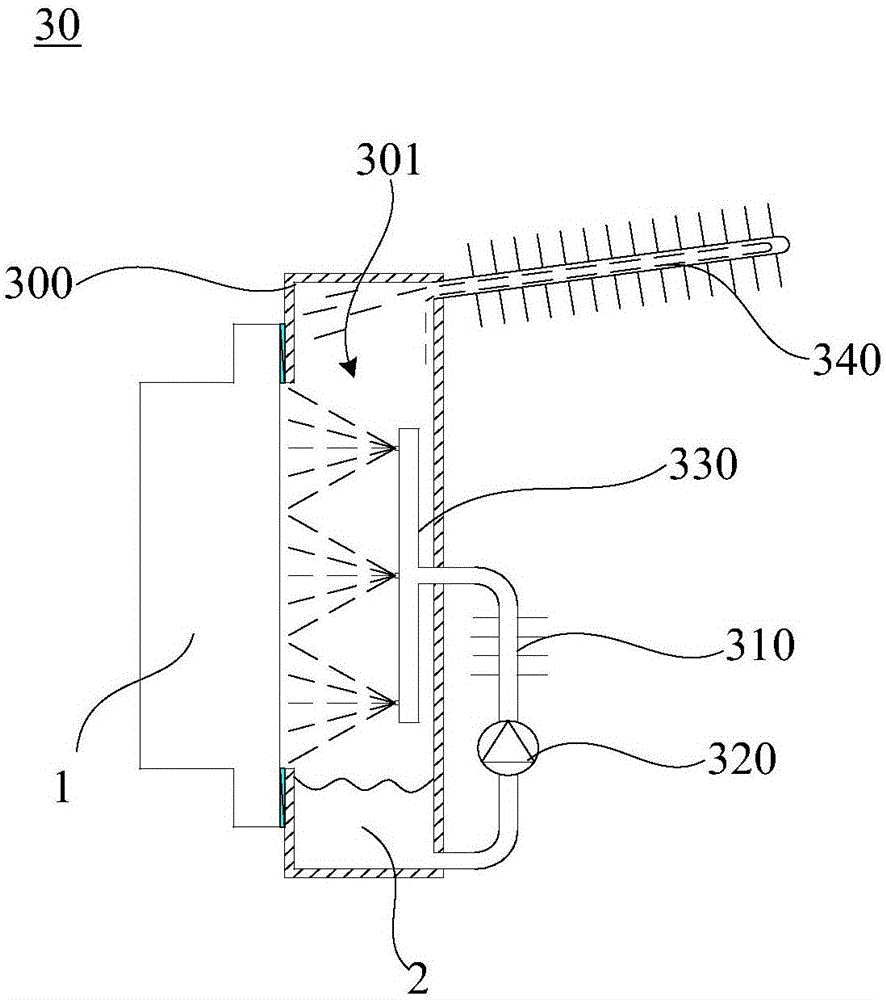

[0048] Please refer to image 3 , this embodiment provides a liquid spray cooler 30 for heat dissipation of the power device 1, including a cooler body 300, a first heat exchange structure 310, a circulation pump 320, a spray structure 330 and a second heat exchange structure 340 .

[0049] The cooler body 300 has a cooling cavity 301 and a cooling port communicating with the cooling cavity 301 . The heat dissipation opening is arranged in the middle of a side wall of the cooler body 300 , and the cooler body 300 at least surrounds the peripheral portion of the heat dissipation opening for sealing fit with the heat dissipation wall through an insulating sealant layer. The cooling channel of the first heat exchange structure 310 communicates with the cooling cavity 301 through a return pipe. The heat exchange structure 310 exchanges heat through water cooling. The circulation pump 320 is arranged on the return pipeline, and is used to make the cooling medium 2 flowing out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com