Cavity-type light emitting diode lamp

A light-emitting diode lamp and cavity-type technology, which is applied to semiconductor devices, light sources, electric light sources, etc. The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

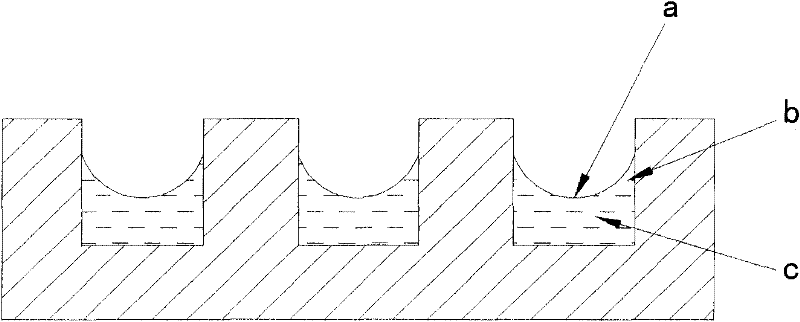

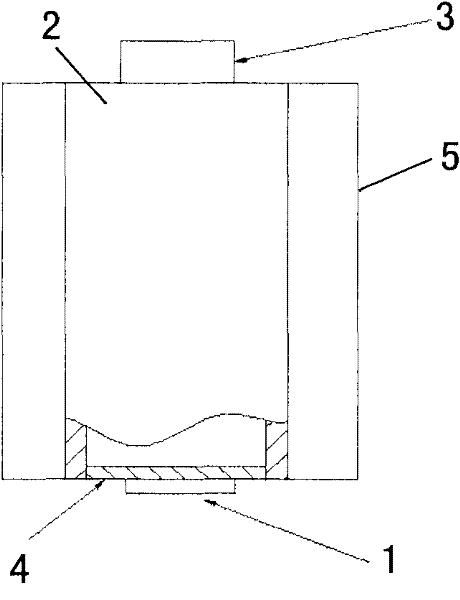

[0036] See Figure 2. The LED chip 1 is directly packaged on the front surface of a micro-groove group metal plate 4 with high thermal conductivity; the back side of the micro-groove group metal plate 4 is processed with a plurality of open rectangular fine channels to form an open rectangular micro-groove group. The width of the open rectangular micro-channels is in the range of 0.05-0.08mm, the depth of the micro-channels is in the range of 0.1-1mm, and the channel spacing is in the range of 1-2mm; the metal plate 4 of the micro-groove group faces outward The back side is packaged on the bottom wall of a cylindrical metal cavity 2 with a cavity inside. The cavity is filled with a liquid working medium with latent heat of vaporization; the outer surface of the cylindrical metal cavity 2 is provided with multiple ribs5. The height of the ribs 5 is in the range of 10-70 mm, the thickness is in the range of 1-5 mm, the length is in the range of 100-250 mm, and the distance betwe...

Embodiment 2

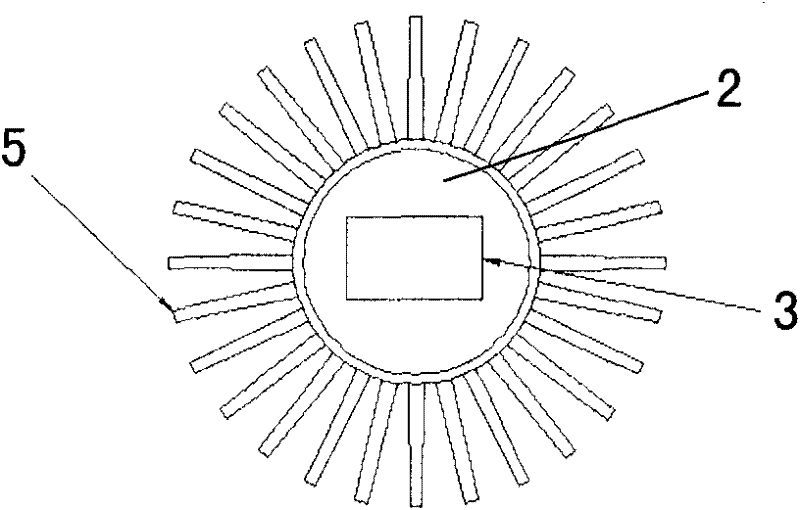

[0038] As shown in Fig. 3, the LED chip 1 is directly packaged on the front surface of a micro-groove group metal plate 4 with high thermal conductivity; the back side of the micro-groove group metal plate 4 is processed with a plurality of open rectangular fine channels to form an open rectangular microgroove group. The width of the open rectangular micro-channels is in the range of 0.04-0.07mm, the depth of the micro-channels is in the range of 0.15-1.2mm, and the channel spacing is in the range of 1-1.5mm; It is packaged outwardly and back inwardly on the cavity wall of a "return" type metal cavity 2 with a cavity inside, and the "return" type metal cavity 2 utilizes two thin-walled rectangular casings After the inner and outer coaxial sleeves are spaced apart, an annular passage is formed between the outer wall of the inner casing and the inner wall of the outer casing, and the upper and lower ends of the passage are sealed to form a closed cavity. Its cross section is li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com