Special-shaped microchannel and exterior corrugated fin integration molding heat exchanger

A technology of corrugated fins and microchannels, which is applied in the field of heat exchangers in which special-shaped microchannels and outer corrugated fins are integrally formed, can solve the high requirements for stability and reliability, reduce system stability and reliability, and solder thickness Uneven sand holes and other problems, to achieve the effect of eliminating contact thermal resistance, reducing volume and weight, and enhancing convective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be noted that the protection scope of the present invention is not limited to the scope described in the embodiments.

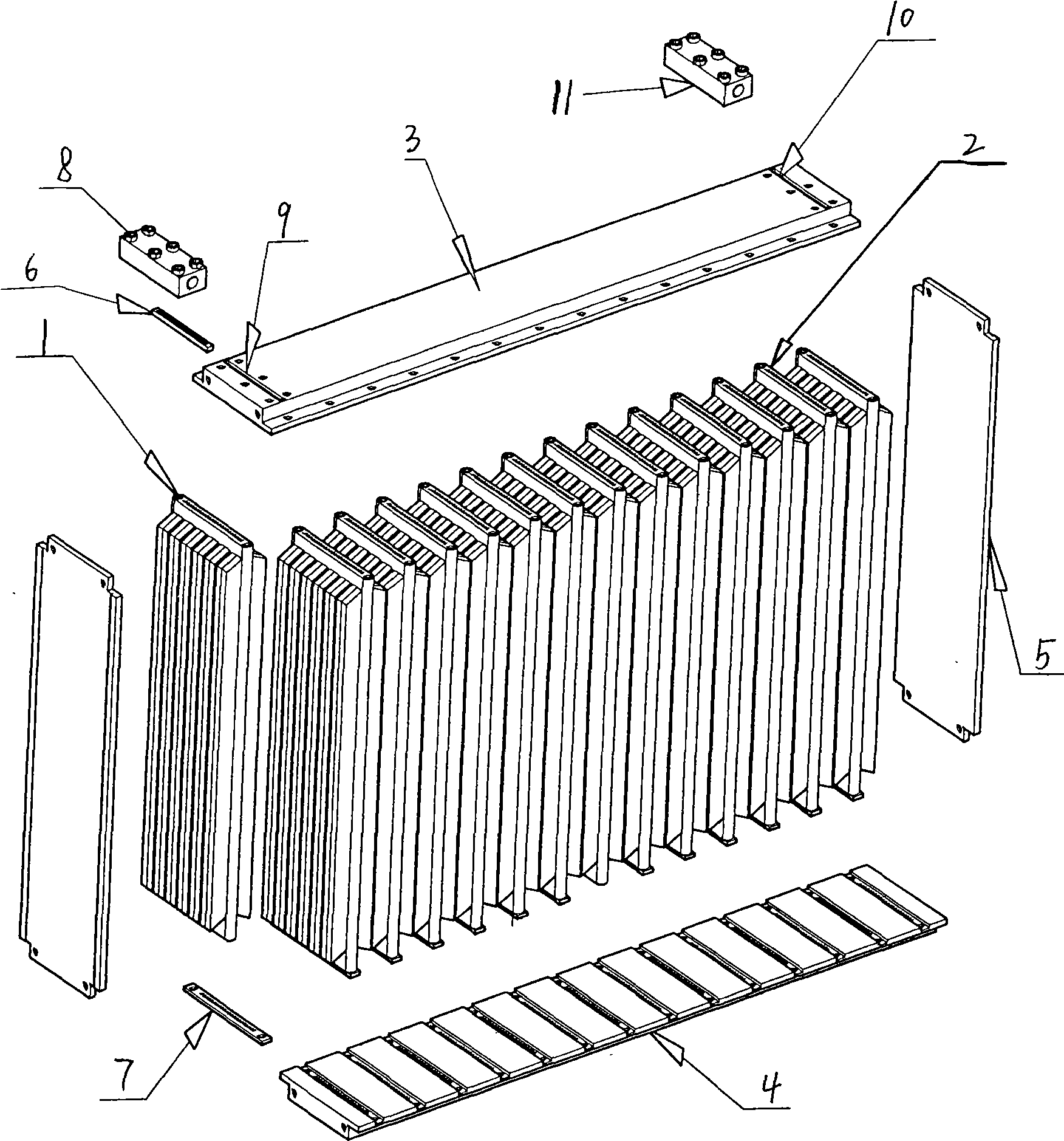

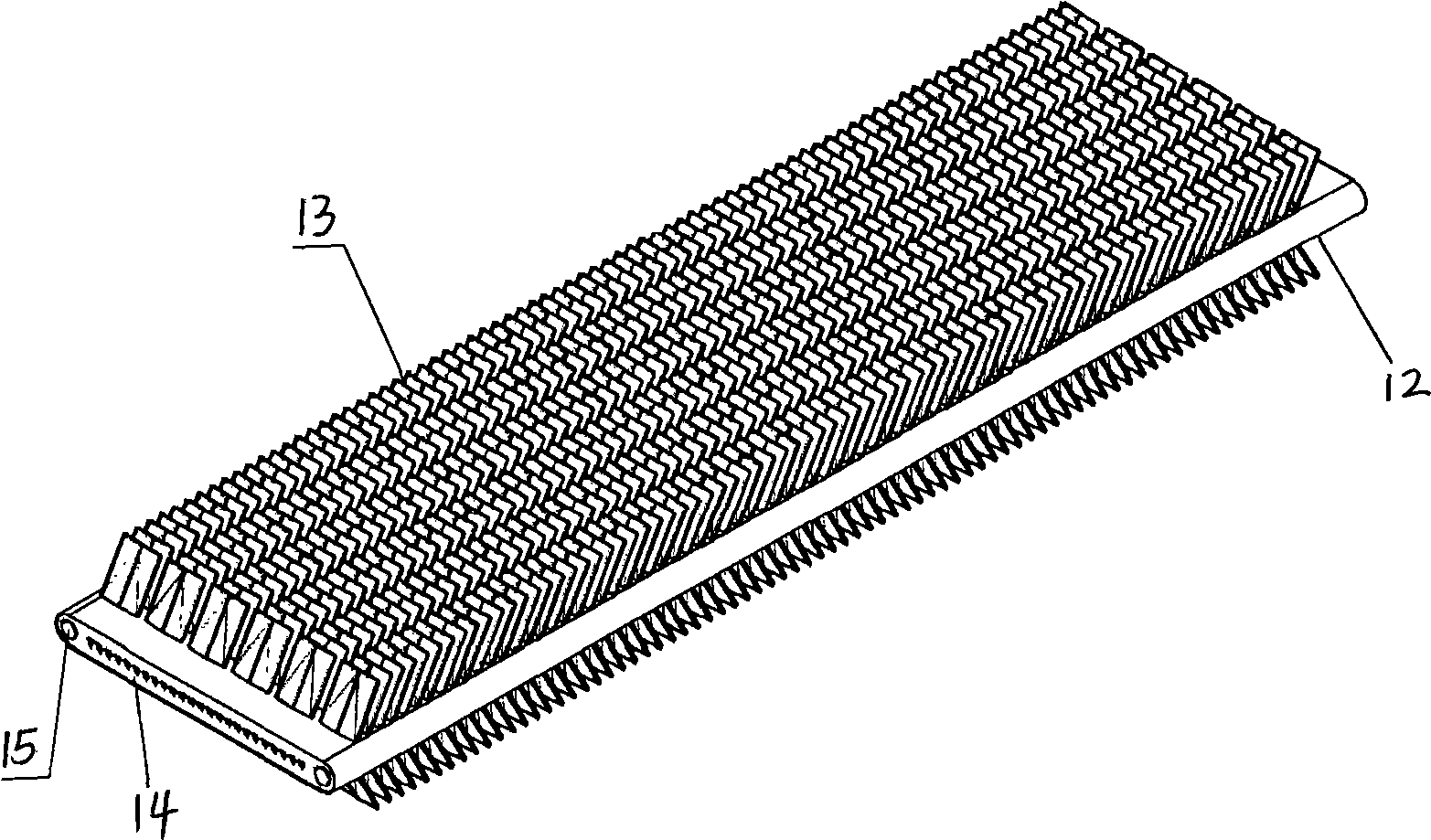

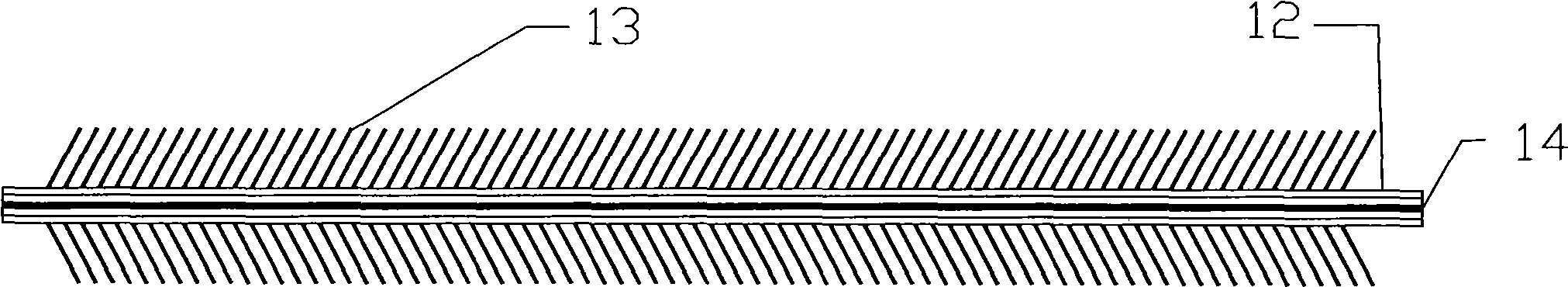

[0029] Such as Figure 1-7 As shown, a heat exchanger in which special-shaped microchannels and outer corrugated fins are integrally formed includes a heat sink group 2, an upper cover plate 3, a lower cover plate 4, a side plate 5, an air inlet 9 and an air outlet 10; Group 2 is formed by connecting a plurality of cooling fins 1 side by side, and is located in a frame structure with openings on both sides composed of the upper cover plate 3, the lower cover plate 4 and the side plate 5. One side of the opening faces the hot side, and the other side To be equipped with a blowing device, the upper cover 3 and the lower cover 4 are connected to the upper and lower ends of the heat sink by screws, and there are silicone gaskets betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com