Regenerative catalytic direct combustion system for treating VOCs waste gas

A regenerative and waste gas technology, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high investment costs and complex device structures, and achieve the effects of low operating costs, low operating costs, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

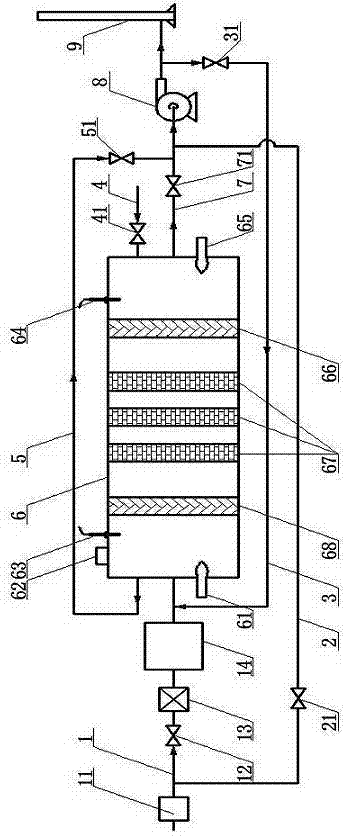

[0013] From figure 1 It can be seen from the figure that a regenerative catalytic direct combustion system for treating VOCs exhaust gas includes exhaust gas inlet pipe 1, bypass pipe 2, flue gas recirculation pipe 3, catalytic direct combustion chamber 6, air inlet pipe 4, air Outlet pipe 5, flue gas outlet pipe 7, induced draft fan 8, exhaust pipe 9, etc. A filter 11, a waste gas inlet valve 12, a flame arrester 13 and a buffer tank 14 are installed on the waste gas inlet pipe 1; a bypass valve 21 is installed on the bypass pipe 2; a flue gas recirculation pipe 3 is installed Valve 31; air inlet valve 41 is installed on air inlet pipe 4; air outlet valve 51 is installed on air outlet pipe 5; smoke outlet valve 71 is installed on smoke outlet pipe 7.

[0014] An explosion-proof door 62 is installed on the top of the catalytic direct combustion chamber 6, and the effect of the explosion-proof door 62 is to release pressure in time when the catalytic direct combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com