Canned linear motor armature and canned linear motor

An electromechanical and electromechanical technology, applied in electromechanical devices, electromechanical components, electrical components, etc., can solve the problems of increasing thermal time constant, increasing thermal resistance, and rising surface temperature of the shell, so as to eliminate the reduction of insulation resistance and reduce viscosity. Power, the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

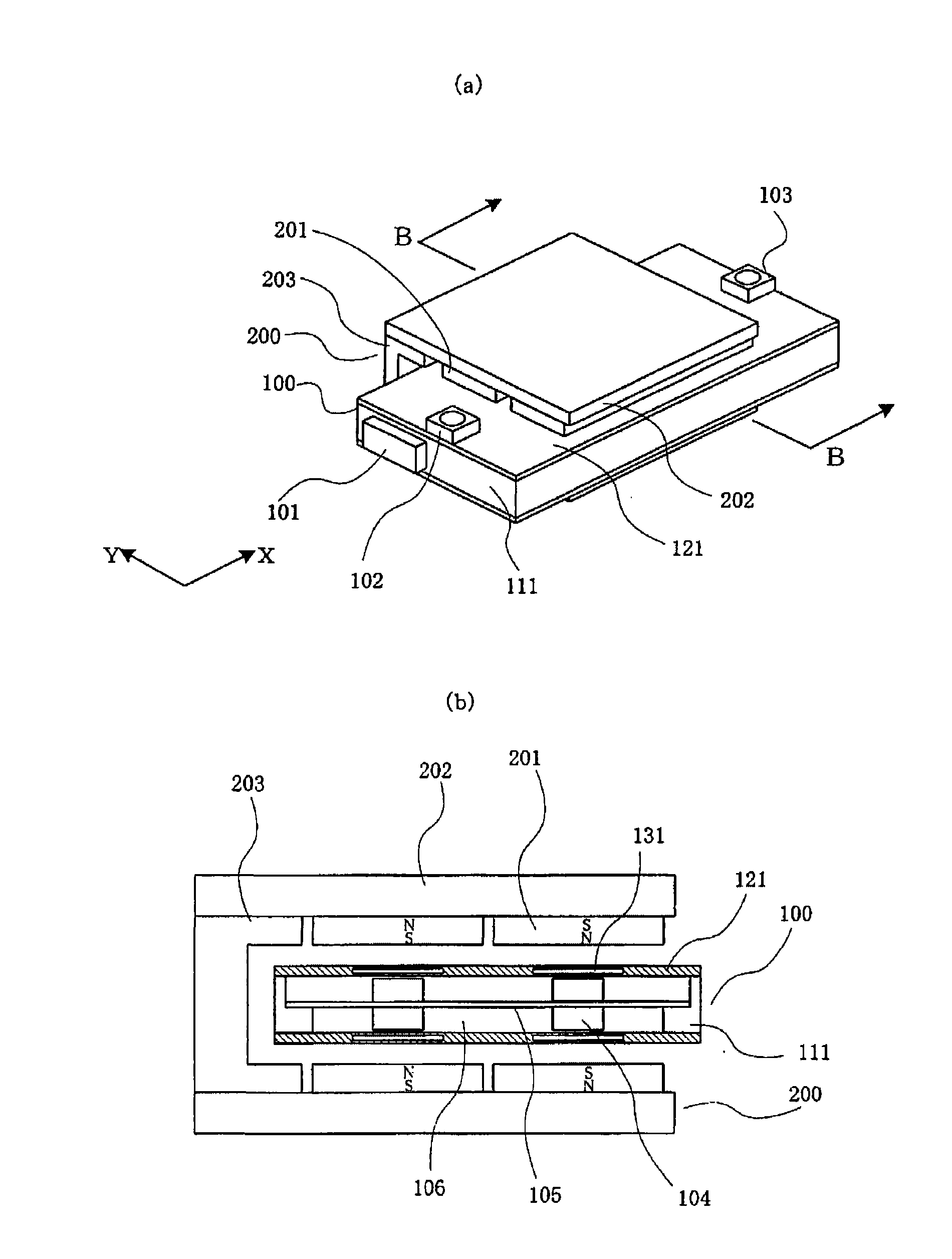

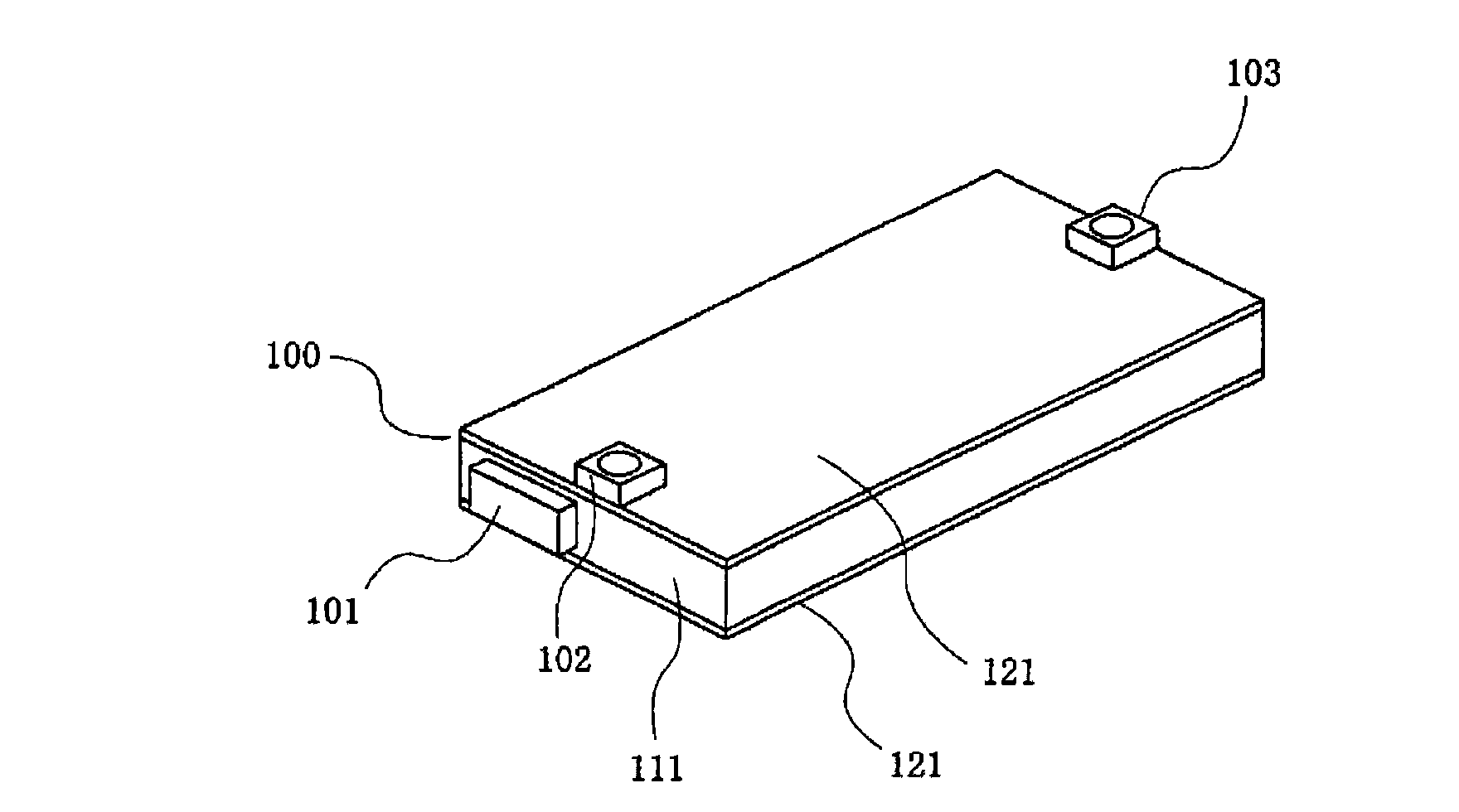

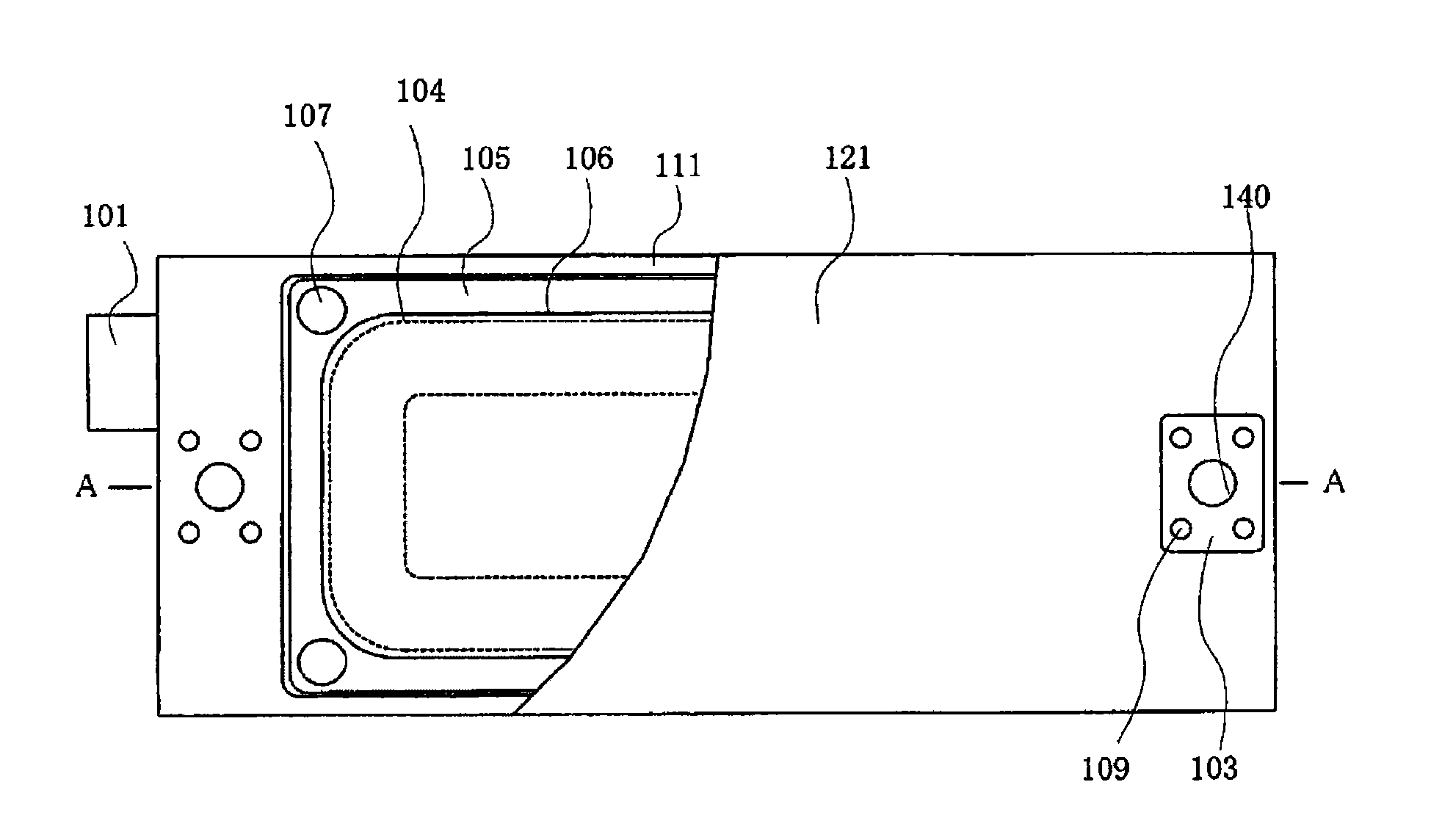

[0129] figure 1 It is a sealed linear motor common to the first to fifth embodiments of the present invention, (a) is an overall perspective view thereof, and (b) is a front sectional view along line B-B viewed from the X direction of (a). in addition, figure 2 It is a perspective view showing the armature of the sealed linear motor according to the first embodiment of the present invention, image 3 From figure 2 The top view of the armature viewed from above, in which a part of the case is cut away to clearly show the positional relationship between the armature coil and the substrate inside the armature, Figure 4 From figure 2 A top view of the armature viewed from above, in which a part of the shell is cut away to clearly show the positional relationship between the armature coil and the refrigerant flow path inside the armature, Figure 5 is along image 3 Side cutaway view of the armature along the line A-A. In addition, the same reference numerals are attache...

Embodiment 2

[0135] Next, a second embodiment of the present invention will be described.

[0136] Figure 6It is a plan view showing the armature viewed from the upper surface of the case of the second embodiment, in which a part of the case is cut away to clearly show the positional relationship between the armature winding and the refrigerant flow path inside the armature. The difference between the second embodiment and the first embodiment is that the refrigerant flow path 132 provided in the case 122 is formed in a meandering shape on the coil side surface of the armature winding 104 .

[0137] According to such a configuration, when the refrigerant flow path is formed in a serpentine shape, the heat transfer coefficient increases with the increase of the refrigerant flow rate, and the heat transfer area from the coil side of the armature winding to the shell increases. Therefore, compared with the first embodiment, the temperature rise of the armature winding can be further reduced...

Embodiment 3

[0139] Next, a third embodiment of the present invention will be described.

[0140] Figure 7 It is a plan view showing the armature viewed from the upper surface of the case of the third embodiment, in which a part of the case is cut away to clearly show the positional relationship between the armature winding and the refrigerant flow path inside the armature. The difference between the third embodiment and the second embodiment is that a long hole 150 is provided in the thick portion of the case 122 .

[0141] According to such a composition, as Figure 38 (b) shows the vortex 152 being refined. Thereby, viscous braking force can be reduced compared with the prior art, the first embodiment, and the second embodiment. Furthermore, since the long hole is provided without contacting the refrigerant flow path, no leakage of the refrigerant from the long hole occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com