Cooling crystallization device

A technology of cooling crystallization and equipment, applied in the direction of heat exchange cooling crystallization, solution crystallization, crystallization auxiliary conditions selection, etc. No fouling and other problems, to achieve the effect of small footprint, high cooling and crystallization efficiency, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

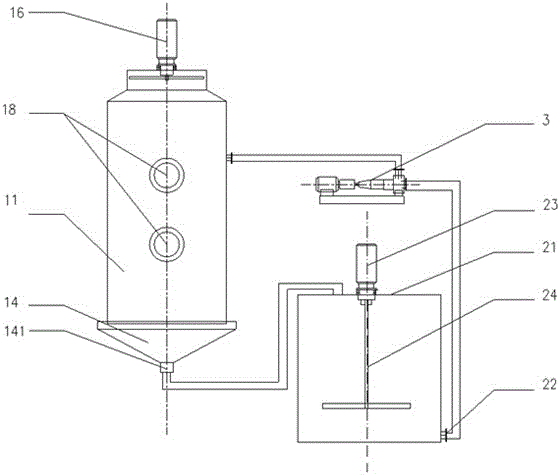

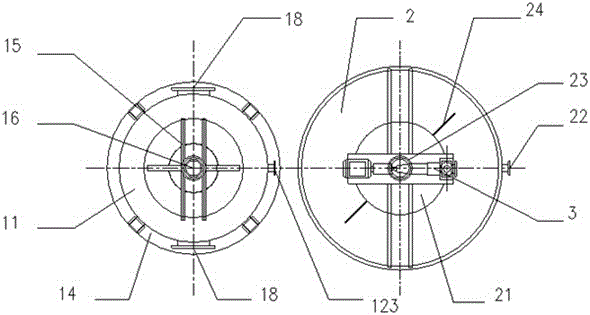

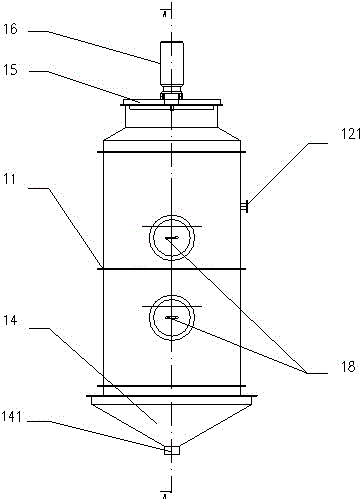

[0048] Such as Figure 1 to Figure 6 As shown, the cooling crystallization equipment includes a cooling tower 1, a crystallization tank 2 and a circulation pump 3; the cooling tower 1 includes a cylinder 11, a spray device 12 and a material sieve plate 13, and the cylinder 11 is provided with an air inlet 111 and an air outlet 112 ,Such as Figure 7 and Figure 8 As shown, the spraying device 12 includes a feed pipe 121, an elbow 122 and a nozzle 123. The feed pipe 121 penetrates from the outside of the cylinder 11 into the cylinder 11. One end of the elbow 122 is connected to the feed pipe 121, and the other end is connected to the nozzle. 123, the nozzle 123 is located in the cylinder 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com