Environment-friendly base oil for fully-enclosed refrigerator oil and preparation method thereof

A technology of refrigerating machine oil and closed refrigeration, which is applied in the direction of base material, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as human health hazards, environmental pollution, and environmental pollution, so as to ensure normal operation, prevent premature separation, and ensure The effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

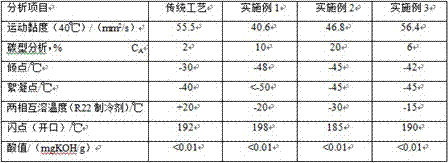

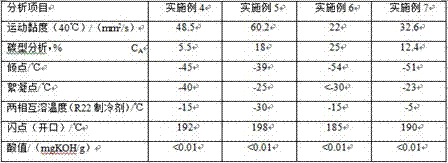

Embodiment 1

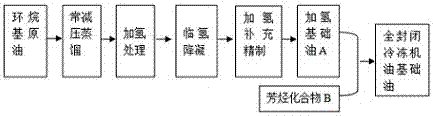

[0025] 1. Preparation of hydrogenated base oil by all-hydrogen combined process

[0026] Using naphthenic crude oil as raw material, using atmospheric and vacuum distillation process to obtain >450°C vacuum distillate oil, and then through the all-hydrogen combination process of "hydrotreatment-hydrodecondensation-hydrogenation supplementary refining", 250-300 °C Fractional distillation to obtain a kinematic viscosity of 22mm at 40 °C 2 / s, %C A 0 hydrogenated base oil.

[0027] In this example, the all-hydrogen combination process conditions are: (1) Hydrotreating section and hydrogen decondensation section: reaction hydrogen partial pressure 8-18MPa, reaction temperature 300-400°C, reaction space velocity 0.3-3h -1 , Hydrogen oil volume ratio 500:1-3000:1; 2) Supplementary hydrogenation refining section: reaction hydrogen partial pressure 8-18MPa, reaction temperature 200-300℃, reaction space velocity 0.3-3h -1 , hydrogen oil volume ratio 200:1-1000;

[0028] For the nap...

Embodiment 2

[0035] 1. Preparation of hydrogenated base oil by all-hydrogen combined process

[0036] The raw materials and preparation method of the hydrogenated base oil in this example are the same as those in Example 1, and fractional distillation at 250-300°C yields a kinematic viscosity of 60mm at 40°C. 2 / s, %C A 0 hydrogenated base oil;

[0037] 2. Configure aromatic compounds

[0038] The aromatic compound of the present embodiment is commercially available No. 22 industrial straight-chain alkylbenzene of Shandong Shouguang Chicheng Industry and Trade Co., Ltd., its %C A (the percentage of carbon atoms on the aromatic ring in the total carbon atoms of the average molecule) is 30%, and the kinematic viscosity at 40°C is 22.7mm 2 / s.

[0039] 3. Preparation of base oil for environmentally friendly fully enclosed refrigeration machine oil

[0040] Heating and mixing aromatic compounds and hydrogenated base oil at 80-100°C to obtain the environment-friendly hermetic refrigerator oi...

Embodiment 3

[0042] 1. Preparation of hydrogenated base oil by all-hydrogen combined process

[0043] The raw materials and preparation method of the hydrogenated base oil in this example are the same as in Example 1, and fractional distillation at 250-300°C yields a kinematic viscosity of 80mm at 40°C. 2 / s, %C A 0 hydrogenated base oil;

[0044] 2. Configure aromatic compounds

[0045] The aromatic compound of this embodiment is dialkylbenzene SynNaph DAB6 commercially available from Shanghai Nake Lubrication Technology Co., Ltd., its %C A (the percentage of carbon atoms on the aromatic ring in the total carbon atoms of the average molecule) is 25%, and the kinematic viscosity at 40°C is 35.5mm 2 / s.

[0046] 3. Preparation of base oil for environmentally friendly fully enclosed refrigeration machine oil

[0047] Heat and mix the aromatic compound and the hydrogenated base oil at 80-100°C to obtain the environment-friendly fully enclosed refrigerator oil base oil. In the base oil, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com