Puffing squeezing technology of rapeseed

A technology of rapeseed and technology, applied in the project field, can solve the problems of incomplete destruction of oil seed cells, high residual oil rate of oil seed meal, high content of non-hydratable phospholipids, etc., to shorten the leaching time, increase the oil yield, and penetrate strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

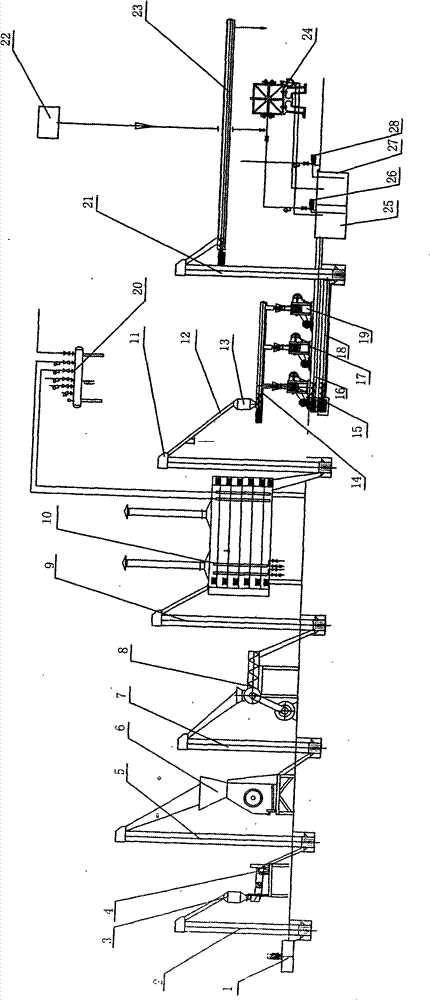

[0006] The specific process of the process of the present invention: the rapeseed enters the feeder 1 and is transported to the No. 1 elevator 2 with a constant flow rate; through the No. 1 magnetic separator 3 . The No. 1 magnetic separator absorbs the iron-containing substances in the rapeseed, and the oil seed enters the destoned cleaning screen 4; the destoned oil is transported to the No. 2 hoist 5, and is transported to the flaking machine 6 through the No. 2 hoist 5; After being processed by the flaking machine 6, the qualified flakes are transported to the No. 3 elevator 7; the oil flakes are transported to the extruder 8 through the No. 3 elevator 7 for puffing treatment. After puffing, the oil in the form of small particles is transported to the flat dryer 10 through the No. 4 hoist 9 to remove excess water; a heating system is provided; the steam delivered from the boiler is distributed to the dryer through the steam distributor 20 Flat-panel dryer 10; rapeseed puff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com