SBS modified asphalt auxiliary agent and SBS modified asphalt

A technology of modified asphalt and additives, which is applied in the field of SBS modified asphalt additives and SBS modified asphalt. Viscosity, the effect of improving anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

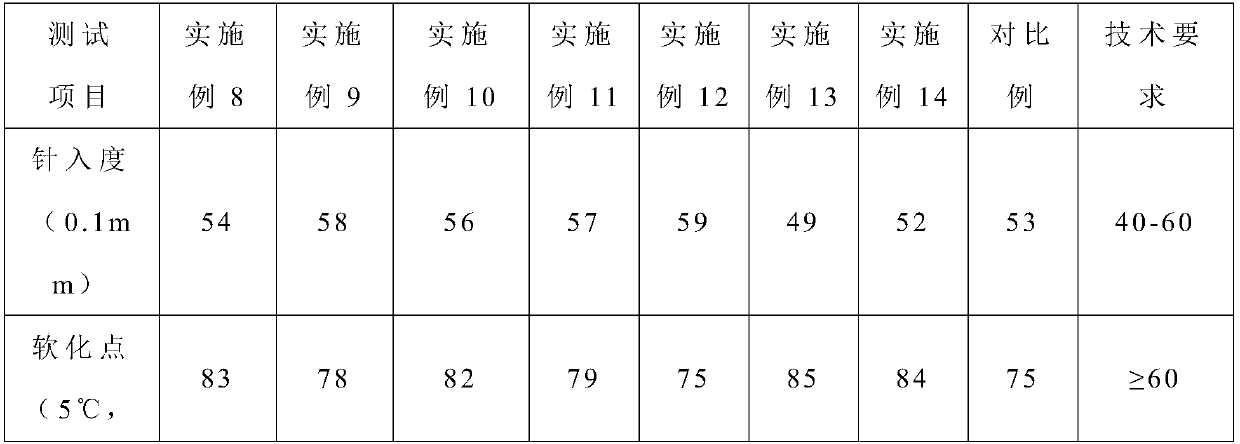

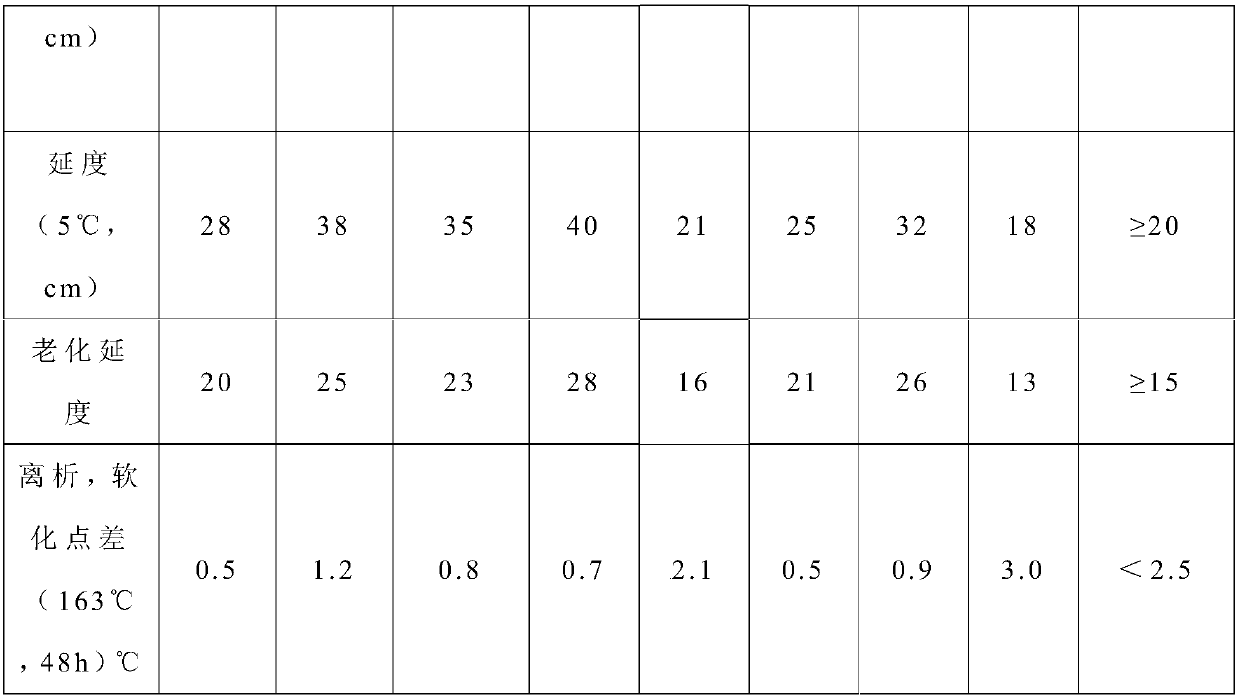

Examples

preparation example Construction

[0021] The present invention also provides a preparation method of SBS modified asphalt additive. The preparation method comprises: heating 50 to 100 parts of white oil at a temperature of 50°C to 70°C, so that the viscosity of the white oil becomes thinner, which is more beneficial to other raw materials Mixing of components: adding 30-50 parts of modified sulfur, 0.5-2 parts of antioxidant, 1-5 parts of suspension aid, and 1-5 parts of plasticizer, stirring and mixing evenly to obtain SBS modified asphalt additive. Wherein, the order of adding 30-50 parts of modified sulfur, 0.5-2 parts of antioxidant, 1-5 parts of suspension aid and 1-5 parts of plasticizer is not particularly limited.

[0022] In a preferred embodiment, the modified sulfur includes the following raw material components in parts by mass: 5-10 parts of aluminum hydroxide, 5-10 parts of magnesium hydroxide, 50-200 parts of water, 50-100 parts of sulfur, 5-10 parts of Polymer wax emulsion, 0.1-1 part of coupli...

Embodiment 1

[0031] Mix 5 parts of 2000-mesh aluminum hydroxide, 5 parts of 2000-mesh magnesium hydroxide and 100 parts of water to prepare an inorganic powder suspension; add 0.3 parts of silane coupling agent, grind to 15 μm, and disperse evenly to obtain an inorganic powder suspension; Add 5 parts of oxidized polyethylene wax emulsion to the inorganic powder suspension, and stir for 30 minutes; then add 50 parts of 200-mesh industrial sulfur, and stir for 60 minutes to obtain a mixture of inorganic powder / polymer wax / sulfur. The above mixture was dried and dehydrated at 80°C, crushed and sieved (200 mesh) to obtain modified sulfur.

[0032] Heat 50 parts of 100# industrial white oil to 50°C, add 0.5 parts of antioxidant 1010, 2 parts of mineral oil emulsifier, 2 parts of dioctyl phthalate, 30 parts of modified sulfur prepared above, and stir for 30 minutes , and stir evenly to obtain the SBS modified asphalt additive of this embodiment.

Embodiment 2

[0034] Mix 8 parts of 3000 mesh aluminum hydroxide, 8 parts of 4000 mesh magnesium hydroxide and 200 parts of water to prepare an inorganic powder suspension; add 1 part of titanate coupling agent, grind to 13 μm, and disperse evenly to obtain an inorganic powder suspension Add 10 parts of oxidized polyethylene wax emulsion to the inorganic powder suspension and stir for 60 minutes; then add 100 parts of 300-mesh industrial sulfur and stir for 120 minutes to obtain a mixture of inorganic powder / polymer wax / sulfur. The above mixture was dried and dehydrated at 80°C, crushed and sieved (200 mesh) to obtain modified sulfur.

[0035] Heat 100 parts of 100# industrial white oil to 60°C, add 2 parts of antioxidant 1076, 5 parts of mineral oil emulsifier, 5 parts of dioctyl maleate, and 50 parts of the modified sulfur prepared above, and stir for 60 minutes. Stir evenly to obtain the SBS modified asphalt additive of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com