A kind of ultraviolet radiation mechanically responsive waterborne polyurethane and preparation method thereof

A water-based polyurethane, mechanical response technology, applied in organic chemistry and other directions, can solve problems such as no water-based polyurethane, and achieve the effects of high elastic modulus, high storage modulus, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

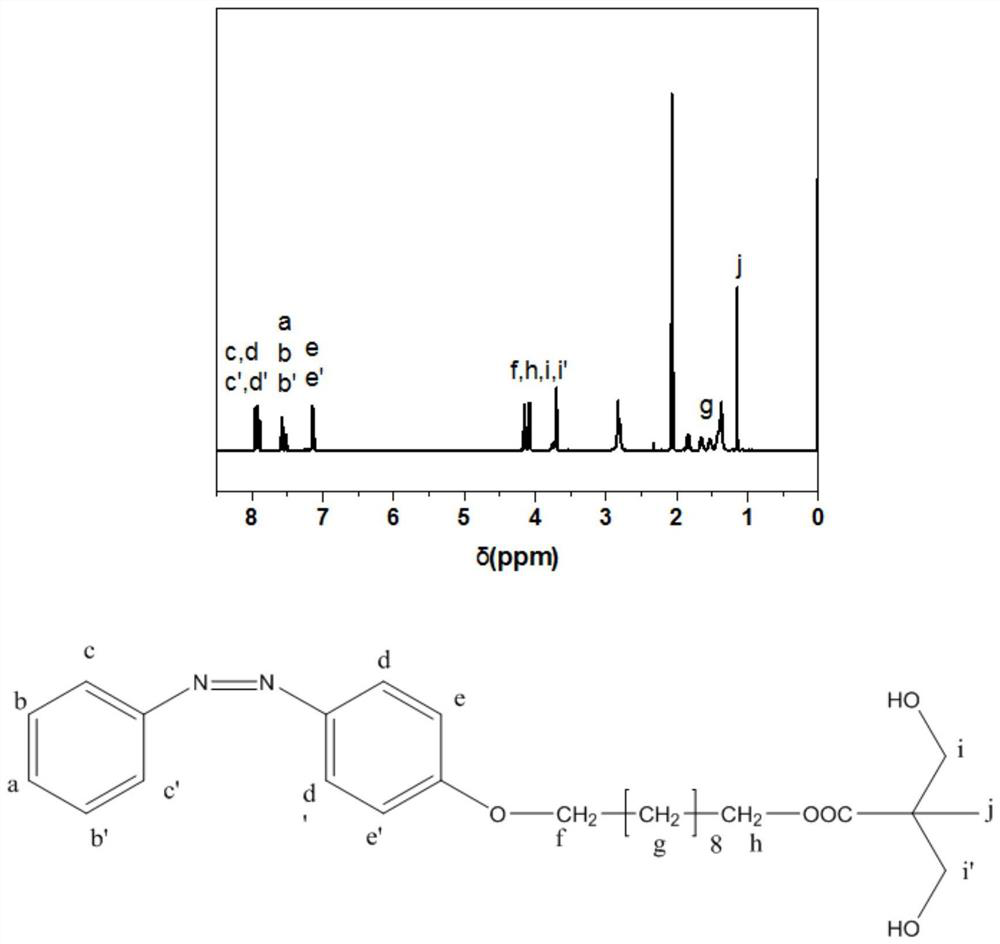

[0051] A small molecular monomer with ultraviolet light irradiation mechanical response activity, the small molecular monomer is 2,2-dimethylolpropionic acid-10-(4-(phenylazo)phenoxy) Decyl ester, its chemical structural formula is as shown in formula (I):

[0052]

[0053] Its preparation method is as follows:

[0054]

[0055] Step 1: 4.96g (25mmol) of 4-(phenyldiazenyl) phenol, 15g (50mmol) of 1-10 dibromononane ( M = 300) and 1.64 g (29 mmol) of potassium hydroxide were dissolved in 150 mL of ethanol and protected with nitrogen, then the solution was refluxed at 60 °C for 12 hours, then allowed to cool at room temperature, and the resulting Orange precipitate (ANB).

[0056]

[0057] Step 2: A mixture of 2,2-hydroxymethylpropionic acid (3.35 g, 25 mmol), potassium hydroxide (88% assay; 1.46 g, 28.5 mmol) and DMF (2 mL) and acetonitrile (18 mL) was heated to 100°C for 1 hour. ANB (8.34 g, 20 mol, DMF 40 mL) was added to the warm solution, and stirring was conti...

Embodiment 2

[0061] A water-based polyurethane elastic gasket, made of the following raw materials in mass percentage: 20% polycaprolactone diol, 10% isocyanate, 5% water-based chain extender, 3% UV mechanical response chain extender, neutralizer 3%, water dispersant 59%.

[0062] The polycaprolactone and polycaprolactone diol 1000 commercially available from Jining Company.

[0063] Described isocyanate is the isophorone diisocyanate of commercially available Aladdin brand.

[0064] The water-based chain extender is commercially available Aladdin brand 2,2-dimethylolpropionic acid and trihydroxypropane.

[0065] The UV-responsive chain extender is the 2,2-dimethylolpropionic acid-10-(4-(phenylazo)phenoxy)decyl ester prepared in Example 1.

[0066] The neutralizing agent is commercially available Aladdin brand triethylamine.

[0067] The preparation method of the ultraviolet mechanical response waterborne polyurethane elasticity specifically includes:

[0068] (1) Heat the vacuum-dried...

Embodiment 3

[0075] A water-based polyurethane elastic gasket, made of the following raw materials in mass percentage: 20% polycaprolactone diol, 10% isocyanate, 5% water-based chain extender, 2% UV mechanical response chain extender, neutralizer 3%, water dispersant 60%.

[0076] The polycaprolactone and polycaprolactone diol 1000 commercially available from Jining Company.

[0077] Described isocyanate is the isophorone diisocyanate of commercially available Aladdin brand.

[0078] The water-based chain extender is commercially available Aladdin brand 2,2-dimethylolpropionic acid and trihydroxypropane.

[0079] The UV-responsive chain extender is the 2,2-dimethylolpropionic acid-10-(4-(phenylazo)phenoxy)decyl ester prepared in Example 1.

[0080] The neutralizing agent is commercially available Aladdin brand triethylamine.

[0081] The preparation method of the ultraviolet mechanical response waterborne polyurethane elasticity specifically includes:

[0082] (1) Heat the vacuum-dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com