A kind of high temperature resistant coating for imitating ceramic fake material of real fire fireplace

A technology for high temperature resistant coatings and ceramic pigments, applied in the field of building decoration materials, can solve problems such as cracks, excessive penetration of the coating layer, and peculiar smell, and achieve the effects of convenient preparation, low cost, and convenient dilution and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

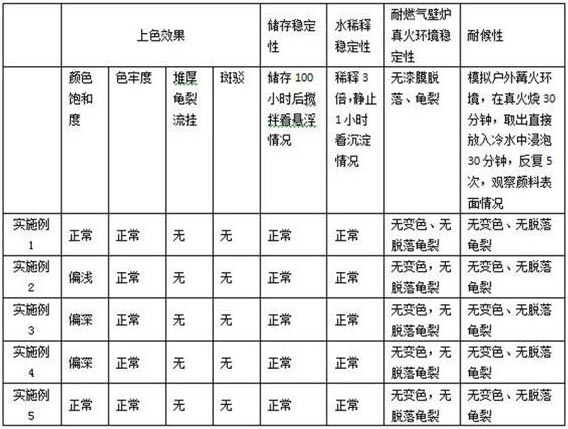

[0031] Example 1, a high-temperature-resistant coating for a real fire fireplace imitation ceramic fake material, by weight, 30 parts of zirconium-iron red ceramic pigment (320 mesh) with a high-temperature resistance grade greater than 1000 degrees, 30 parts of coating-grade talc powder (whiteness 75 %, fineness <= 45μm) 15 parts, bentonite (300 mesh) 3 parts, cationic polyacrylamide (molecular weight 8 million) aqueous solution 2 parts with a mass percentage concentration of 1%, aluminum sol (solid content 30%, PH=7 , colloidal particle size 60 nanometers) 35 parts, water 15 parts, mixed evenly, emulsified at high speed in an emulsifier, the performance indicators are shown in Table 1.

Embodiment 2

[0032] Example 2, a high-temperature-resistant coating for a real-fire fireplace imitation ceramic fake material, by weight, 20 parts of cobalt black ceramic pigment (320 mesh) with a high-temperature resistance grade greater than 1000 degrees, coating-grade talcum powder (whiteness 75% , fineness <= 45μm) 3 parts, bentonite (300 mesh) 1 part, cationic polyacrylamide (molecular weight 8 million) aqueous solution 5 parts with a mass percentage concentration of 0.01%, aluminum sol (solid content 30%, PH=5, Mix 30 parts of colloidal particles with a particle size of 60 nanometers) and 41 parts of water evenly, and emulsify at high speed in an emulsifying machine. The performance indicators are shown in Table 1.

Embodiment 3

[0033] Example 3, a high-temperature-resistant coating for a real-fire fireplace imitation ceramic false material, by weight, 40 parts of cobalt blue ceramic pigment (320 mesh) with a high-temperature resistance grade greater than 1000 degrees, coating-grade talcum powder (whiteness 75% , fineness <= 45μm) 15 parts, bentonite (300 mesh) 2 parts, cationic polyacrylamide (molecular weight 8 million) aqueous solution 3 parts with a mass percentage concentration of 0.1%, silica sol (solid content 30%, PH=8, Mix 20 parts of colloidal particles (15 nanometers in diameter) and 20 parts of water evenly, and emulsify at high speed in an emulsifying machine. The performance indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com