Method for producing acrylic ester copolymer

A technology of acrylate and production method, applied in the field of organic adhesives, can solve the problems of low tensile strength, peculiar smell in burning, cracking of gaskets, etc., and achieve the effects of reasonable bonding performance, reduction of burning peculiar smell, and easy packaging and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

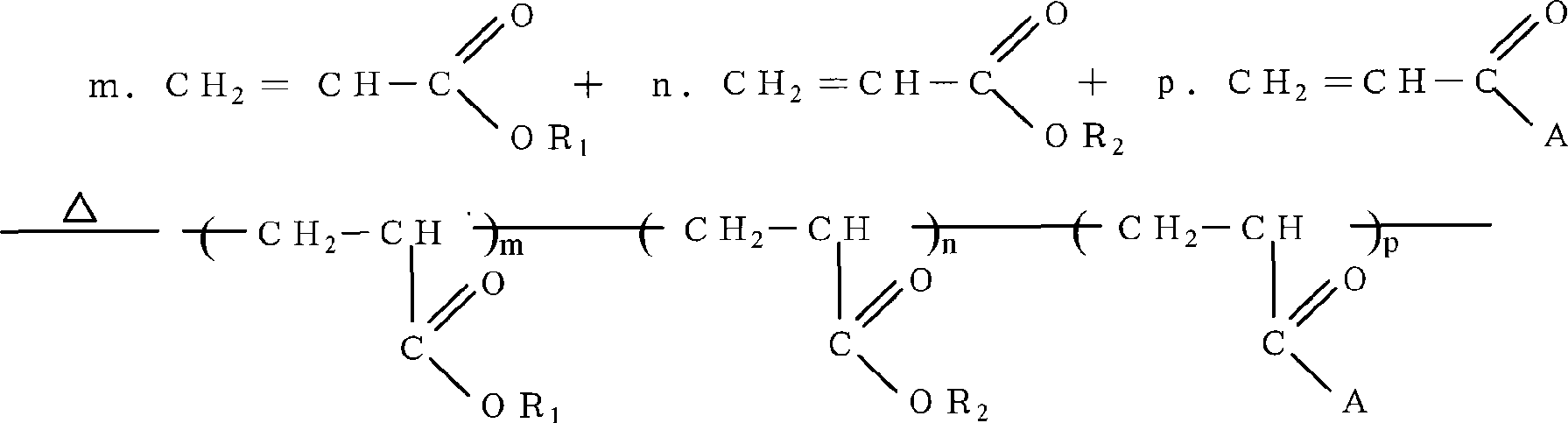

Method used

Image

Examples

Embodiment

[0025] (1) 45% of butyl acrylate, 44% of ethyl acrylate, 10.2% of vinyl acetate, and 0.8% of coupling agent are physically mixed and stirred evenly to form a monomer solution;

[0026] (2) 5% of N-methylolpropionamide, 1% of OP-10, 0.5% of Span-85, 1% of fast penetrant T1, and the remainder of water are physically mixed and stirred evenly to form an emulsifier solution;

[0027] (3) Physically mix 35% of the monomer solution obtained in step (1) with 65% of the emulsifier solution obtained in step (2) and stir evenly to form an emulsion;

[0028] (4) 0.2% of OP-10, 20% of the emulsion obtained in step (3), and the water balance are physically mixed and stirred evenly to form a primer solution;

[0029] (5) After physically mixing 1% of ammonium persulfate and 99% of water, stir evenly to form an initiator solution;

[0030] (6) When the primer solution obtained in step (4) is heated to 45° C., add the initiator solution obtained in step (5), the amount of the initiator soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com