Method for processing nitrogen oxide exhaust

A technology for treating nitrogen oxides and waste gas, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of low treatment cost and insignificant treatment effect, and achieve low cost, stable reduction treatment solution, and improved Effects of Processing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

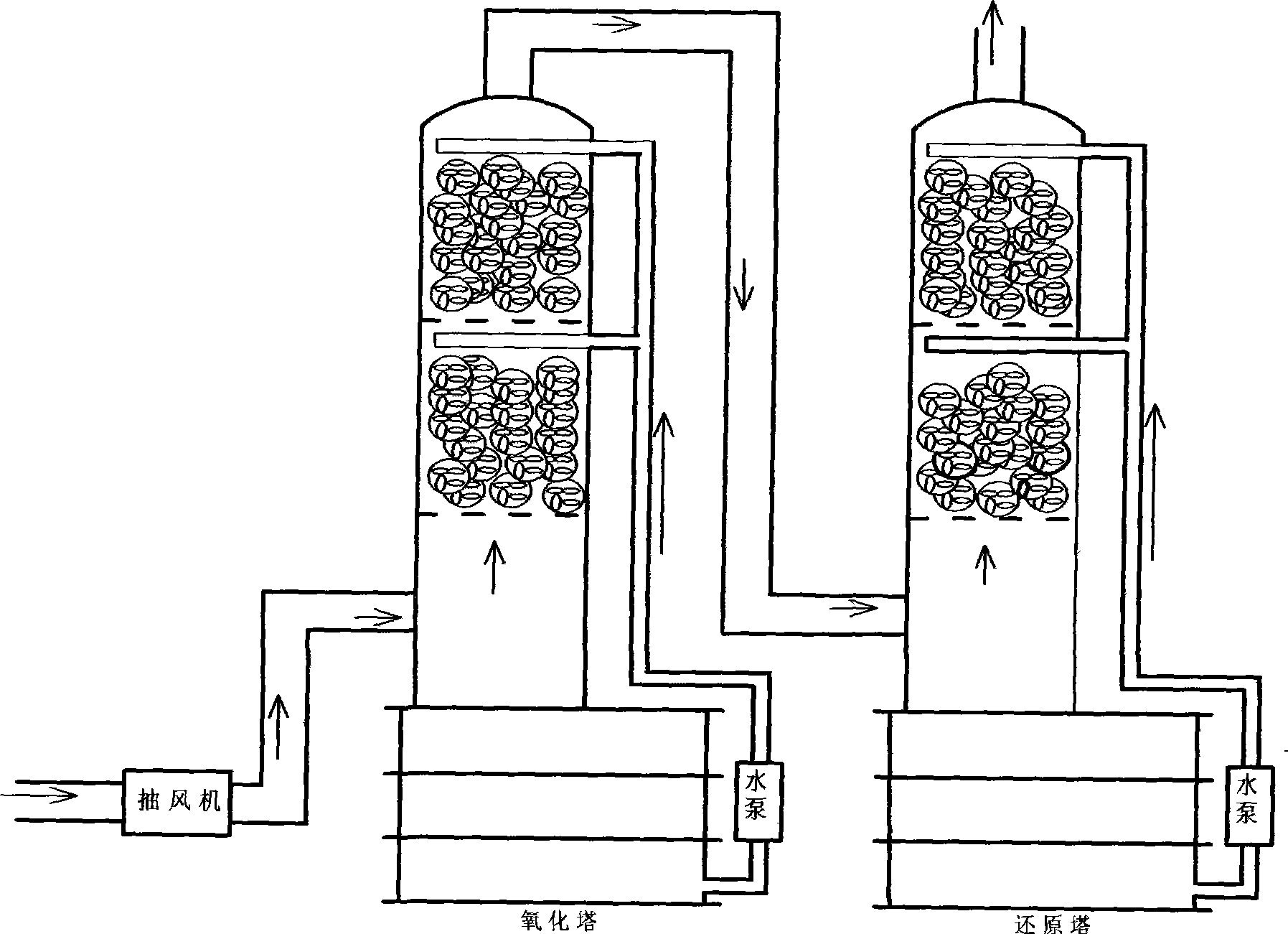

[0019] Combine below figure 1 The present invention is further described as follows with examples.

[0020] Depend on figure 1 It can be seen that the nitrogen oxide waste gas is first oxidized and absorbed in the oxidation tower A, and then reduced in the reduction tower B. Nitrogen oxide waste gas is pumped into the bottom of the treatment tower through the fan 1 and the exhaust pipe 2. The waste gas moves upward through the multi-faceted hollow filler 4 from bottom to top, and the treatment liquid is pressed into the treatment tower by the water pump 7 through the water spray pipe 6 and the nozzle 5. In the tower, the treatment liquid sprayed downward through the nozzle 5 fully contacts and reacts with the countercurrent waste gas, and after stratified treatment, the treatment liquid flows back into the treatment liquid storage tank 3, and the treated waste gas is discharged into the atmosphere through the exhaust pipe 8.

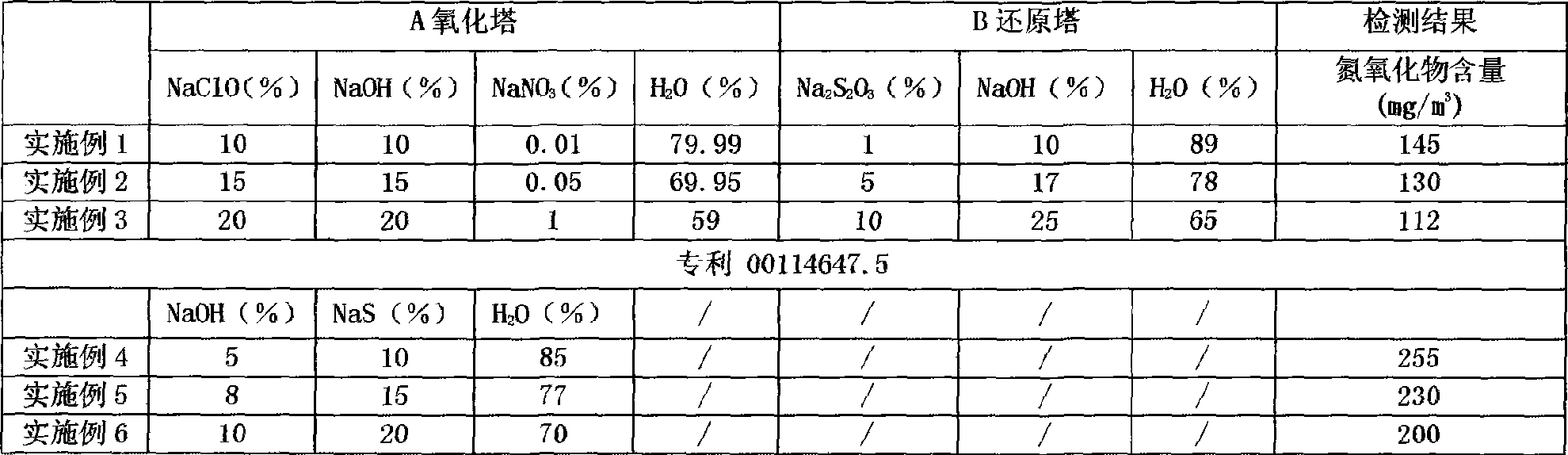

[0021] See Table 1 for the formulations of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com