PU smell removing polyurethane coating as well as preparation and application thereof

A polyurethane coating and odor-cleaning technology, which is applied in the coating field, can solve the problems such as product environmental protection indicators not up to standard, and achieve the effects of excellent fullness, low odor and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Preparation of acrylic modified polyester resin

[0060] 1) Put 1000mL (860g) of xylene into the flask, heat to 140°C under reflux for half an hour, add 10% methyl methacrylate, 1% acrylic acid, 15% ethyl methacrylate according to the weight ratio of xylene , 15% butyl methacrylate, 20% styrene, half of the TBPB1% mixture, drip it in 4h hours, keep it for 1h; then add the remaining TBPB and xylene mixture (including TBPBwt50%), and take 40min After dripping, keep warm for 1h; cool down and discharge;

[0061] 2) Mix 20 parts of acrylic prepolymer, 15 parts of adipic acid, 20 parts of phthalic anhydride, 20 parts of glycerol, 2 parts of maleic anhydride, and 50 parts of xylene into a four-necked flask, add carbon dioxide gas, heat up, and reflux Keep the temperature at 150℃ for 2h, then heat it up to 220~230℃ at a rate of 10~12℃ / hour, keep it for esterification until the acid value≤10mgKOH / g, then cool down and discharge. The product is labeled S5051.

[0062] The...

Embodiment 2

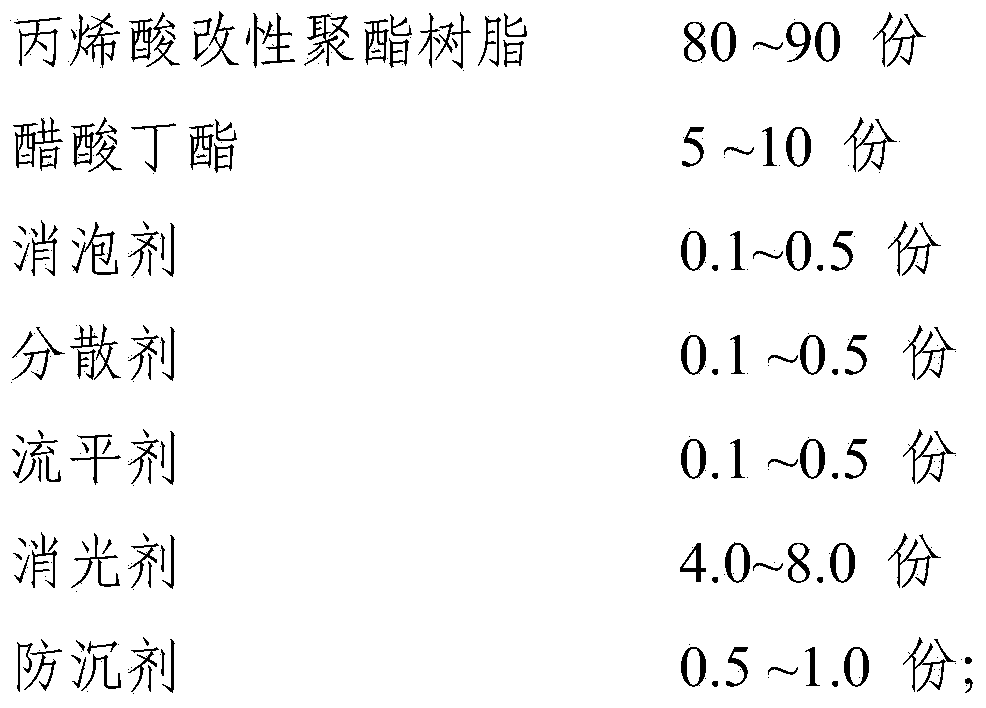

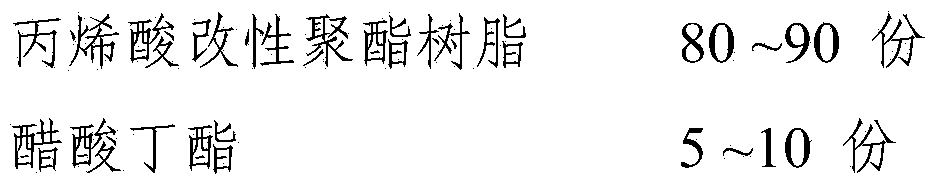

[0064] Prepare PU pure odor polyurethane coating according to the following ratio:

[0065] A component: S505189kg, butyl acetate 5kg, DeuRheo2290.5kg, Defom53000.3kg, EFKA-E40610.3kg, BYK-3060.4kg, amorphous silica 4.6kg;

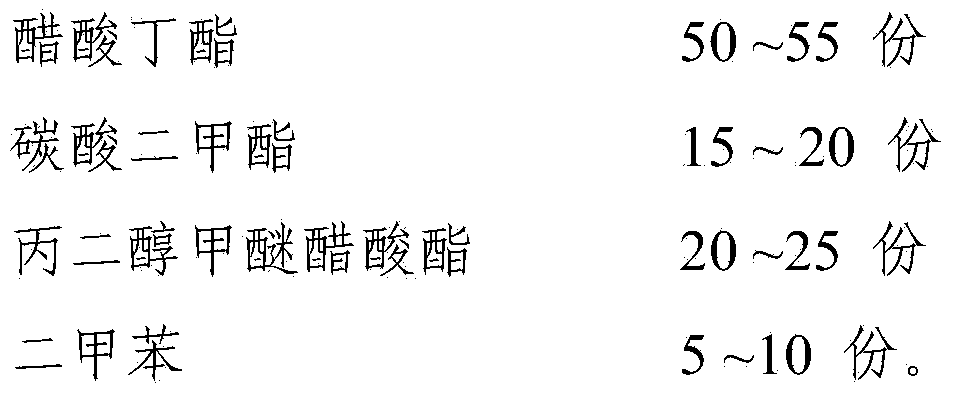

[0066] B component: BAYER L-7510kg, Desmodur HL60kg, butyl acetate 25kg;

[0067] C component: 25kg of butyl acetate, 10kg of dimethyl carbonate, 10kg of propylene glycol methyl ether acetate, 5kg of xylene;

[0068] The mixing weight ratio of component A, component B and component C is 100:80:50.

[0069] The preparation method includes the following steps:

[0070] (1) Preparation of component A:

[0071] 1) Put the S5051, butyl acetate, and EFKA-E4061 in the above ratio into the reactor and stir at 600r / min for 30min to prepare a resin mixture;

[0072] 2) Add the above-mentioned amorphous silica and DeuRheo229 slowly into the reactor with the resin mixture, and disperse for 20min at a speed of 900r / min;

[0073] 3) Add Defom5300 and BYK-306 in the above-mentioned ra...

Embodiment 3

[0080] Prepare PU pure odor polyurethane coating according to the following ratio:

[0081] A component: S5051 85kg, butyl acetate 6kg, DeuRheo229 0.6kg, BYK-065 0.1kg, EFKA-4010 0.4kg, BYK-333 0.5kg, amorphous silica 7.4kg;

[0082] B component: BAYER L-75 20kg, Desmodur HL 40kg, butyl acetate 20kg;

[0083] C component: 15kg of butyl acetate, 6kg of dimethyl carbonate, 6kg of propylene glycol ethyl ether acetate, 3kg of xylene;

[0084] The mixing weight ratio of component A, component B and component C is 100:100:30.

[0085] The preparation method includes the following steps:

[0086] (1) Preparation of component A:

[0087] 1) Put the S5051, butyl acetate, and EFKA-4010 in the above ratio into the reactor and stir at 800r / min for 20min to prepare a resin mixture;

[0088] 2) Add amorphous silica and DeuRheo229 slowly to the reactor with the resin mixture, and disperse at 700r / min for 30min;

[0089] 3) Add BYK-065 and BYK-333 to the reactor, and stir at 800r / min for 20min;

[0090] 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com