High protein peptide milk powder and its production process

A production method and high-protein technology, applied in the field of high-protein peptide milk powder and its production, can solve the problems of market and application scope limitations, no breakthroughs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: the weight ratio composition of a kind of high-protein peptide milk powder is:

[0050] (1) High protein content: 60%; small peptide content (molecular weight: 200-3000): 20%;

[0051](2) The balance is conventional milk powder ingredients.

Embodiment 2

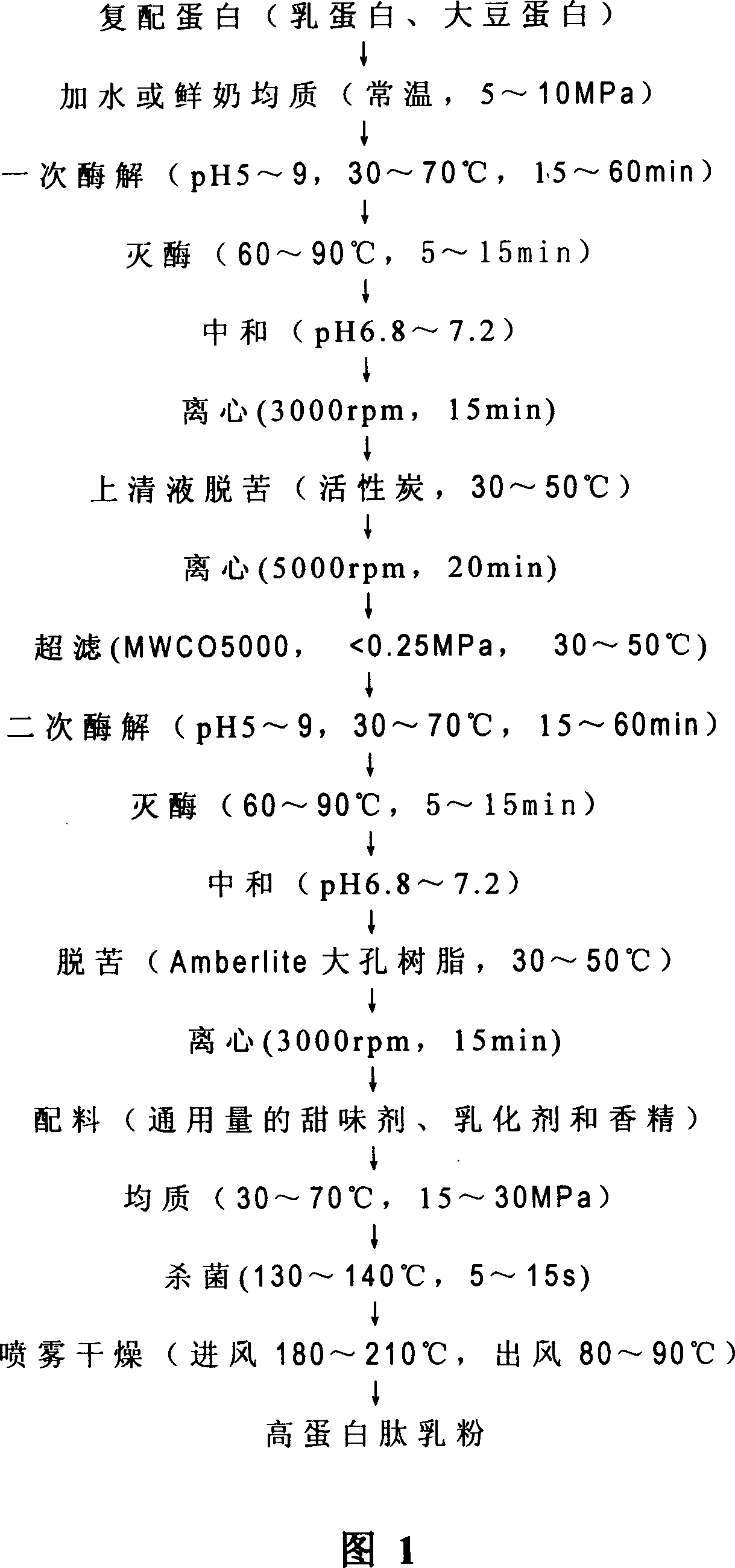

[0052] Embodiment 2: a. contain protein 40~60g (peptide 5~20g) by every 100 grams of products, and the product does not have obvious bitter taste and peculiar smell index requirement, prepare required raw material and processing aid; Protein is milk protein and A mixture of soybean protein; the enzyme is one or several mixtures of alkaline protease, neutral protease, papain, bromelain, flavor enzyme, etc. b. Measure and mix the raw soybean protein and add water to 1000ml to maintain the weight ratio of solids 10-20%; c. Adjust temperature to 35-50°C, pH 7.0-7.5, hydrolyze with neutral protease, alkaline protease and flavor enzyme (2:1:1) for 30-60 minutes; d. Inactivate enzyme, 60 ~90℃, 5~15min; e. Neutralize with NaOH until the pH value is 6.8~7.2; f. Centrifuge and remove residue at 3000rpm, 15min; g. Treat the hydrolyzate with activated carbon adsorption for 30~60min, the temperature is 40~60℃ , the weight ratio of activated carbon is 0.5-2%; at h.5000rpm, centrifuge for 20...

Embodiment 3

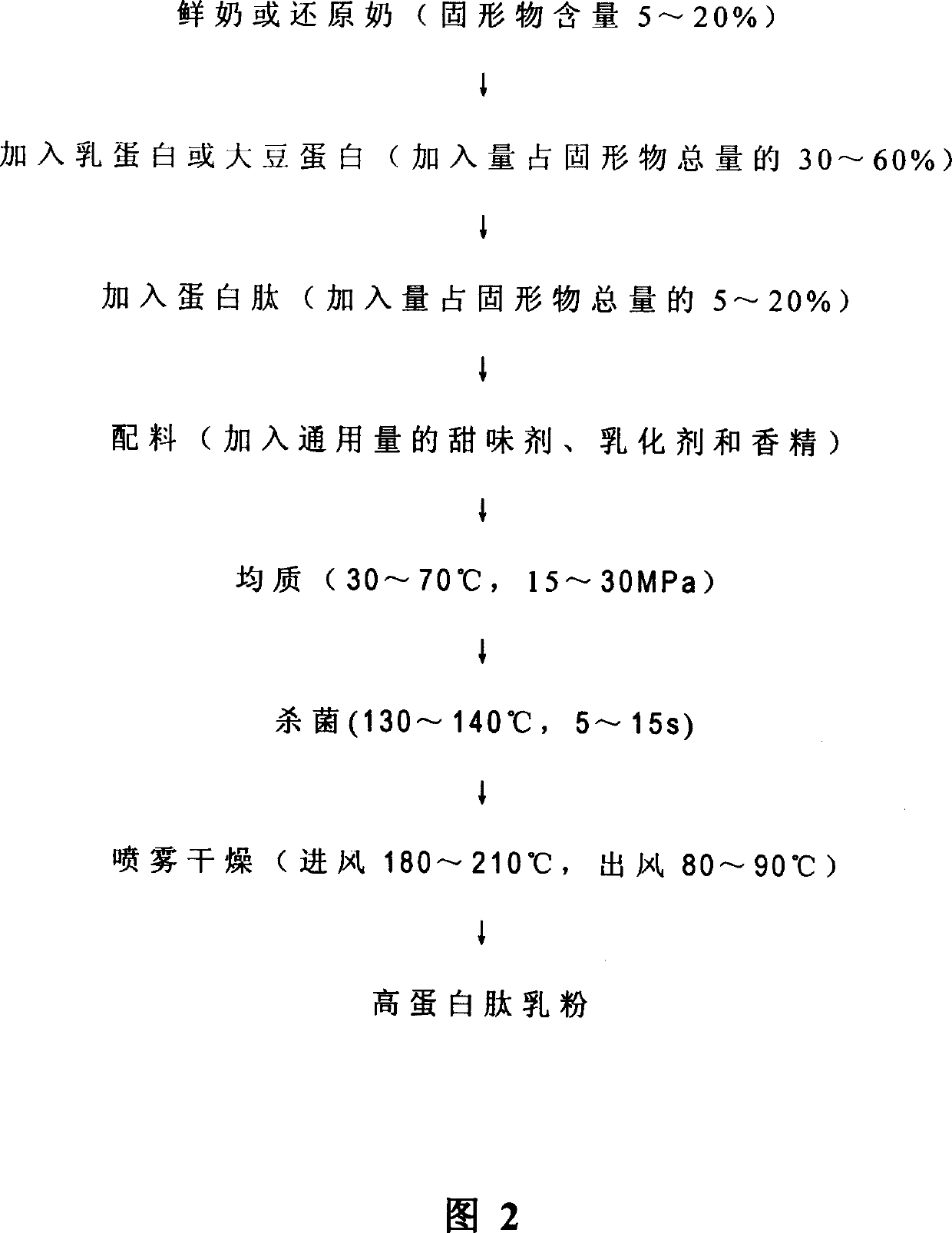

[0053] Embodiment 3: a. contain protein 40~60g (wherein small peptide 5~20g) by every 100 grams of products, and the product does not have obvious bitter taste and peculiar smell index requirement, prepare required raw material and processing aid; Protein is milk A mixture of protein and soybean protein; protein peptide is one or several mixtures of milk protein peptide, soybean protein peptide, peanut protein peptide, rice protein peptide, etc.; b. raw milk protein and soybean protein are metered and mixed with solvent (water or fresh milk) to 1000ml; c. Add measured protein peptides to ensure that the peptide content of the finished product is 5-20%; d. Add general-purpose sweeteners, emulsifiers, stabilizers and flavors and fragrances, and mix thoroughly; e.15 Homogenize 1-2 times under a pressure of ~30MPa; f. Sterilize for 5-15s at 130-140°C; g. Spray drying, inlet air temperature 180-210°C, outlet air temperature 80-90°C; h. Cooling Pack at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com