Preparation method of fish scale collagen and application of fish scale collagen as antioxidant and enzyme inhibitor

A technology of fish scale collagen and compound protease, which is applied in food ingredients as antioxidants, preparation methods and applications of peptides, can solve the problems of poor flavor and poor appearance of fish scale collagen, achieve high crowd acceptance, and avoid adverse effects , The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

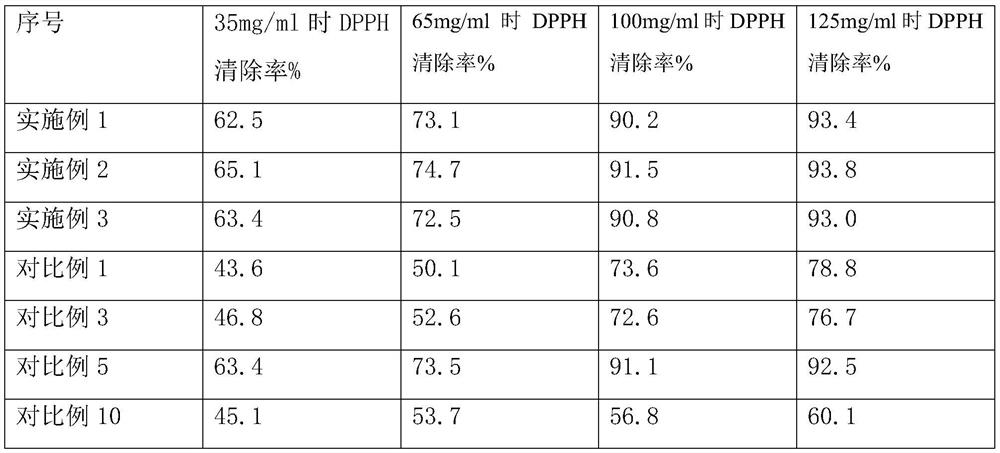

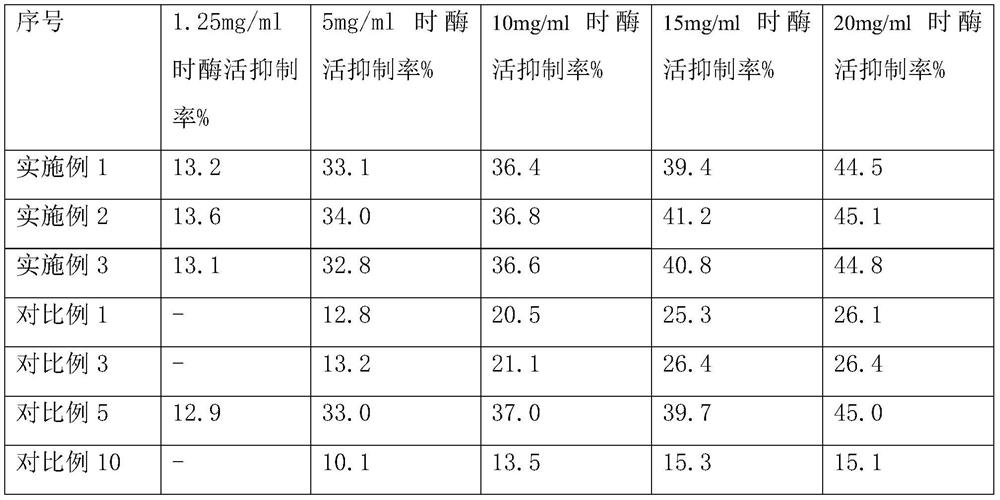

Embodiment 1

[0023] The present embodiment provides a kind of preparation method of fish scale collagen, it comprises the steps:

[0024] Take 5kg of fresh fish scales as raw material, add 7.5kg of water and 0.25kg of citric acid, then cook at 65°C for 4 hours to make it into a paste, then cool down to below 40°C to obtain a paste, add to the paste 0.0065kg neutral protease and 0.0004kg papain, and adjust the pH of the mixture to 7.0 for hydrolysis, keep the temperature at 40-45°C during the hydrolysis process, adjust the pH to 6.5 after hydrolysis for 3 hours, and then filter to obtain the primary filtrate. Use a filter membrane with a filter hole of 3000D to perform membrane filtration to obtain a dilute liquid with a solid content of 8.1%, then adjust the pH of the dilute liquid to 4.5 and then pass through a carbon fiber column for decolorization, and then adjust the pH of the resultant after decolorization by the carbon fiber column To 6.5 to get the decolorized material liquid, the g...

Embodiment 2

[0026] The present embodiment provides a kind of preparation method of fish scale collagen, it comprises the steps:

[0027] Take 5kg of fresh fish scales as raw material, add 8.75kg of water and 0.35kg of citric acid, then cook at 70°C for 5 hours to make it into a paste, then cool down to below 40°C to obtain a paste, add to the paste 0.0075kg neutral protease and 0.0005kg papain, and adjust the pH of the mixture to 6.5 for hydrolysis. During the hydrolysis process, keep the temperature at 40-45°C. After hydrolysis for 4 hours, adjust the pH to 6.2 and then filter to obtain the primary filtrate. The obtained primary filtrate continues Use a filter membrane with a filter hole of 6000D to perform membrane filtration to obtain a dilute solution with a solid content of 10.2%, then adjust the pH of the dilute solution to 4.2, and then pass through a carbon fiber column for decolorization, and then adjust the pH of the resultant after decolorization by the carbon fiber column To 6...

Embodiment 3

[0029] The present embodiment provides a kind of preparation method of fish scale collagen, it comprises the steps:

[0030] Take 5kg of fresh fish scales as raw material, add 10kg of water and 0.45kg of citric acid, then cook at 75°C for 5.5h to make it into a paste, then cool down to below 40°C to obtain a paste, add to the paste 0.0085kg neutral protease and 0.0006kg papain, and adjust the pH of the mixture to 6.0 for hydrolysis, keep the temperature at 40-45°C during the hydrolysis process, adjust the pH to 6.0 after 4.5 hours of hydrolysis and then filter to obtain the primary filtrate. Continue to carry out membrane filtration with a filter membrane with a filter hole of 10000D to obtain a thinner solution with a solid content of 11.9%, then adjust the pH of the thinner solution to 4.0 and pass through a carbon fiber column for decolorization, and adjust the resulting product after decolorization by the carbon fiber column pH to 6.0 to obtain the decolorized material liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com