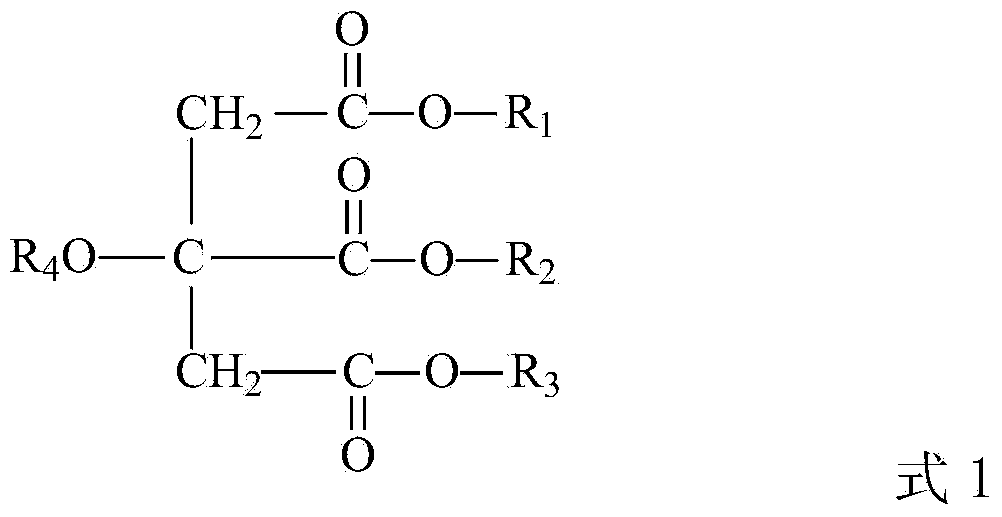

Novel plasticizer and preparation method thereof

A technology of plasticizer and citric acid, which is applied in the field of polymer material additives and its preparation, can solve the problems of high volatility, low plasticizing efficiency and high economic cost of citric acid high-carbon alcohol ester plasticizers, and achieve Effect of low volatility and excellent plasticizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

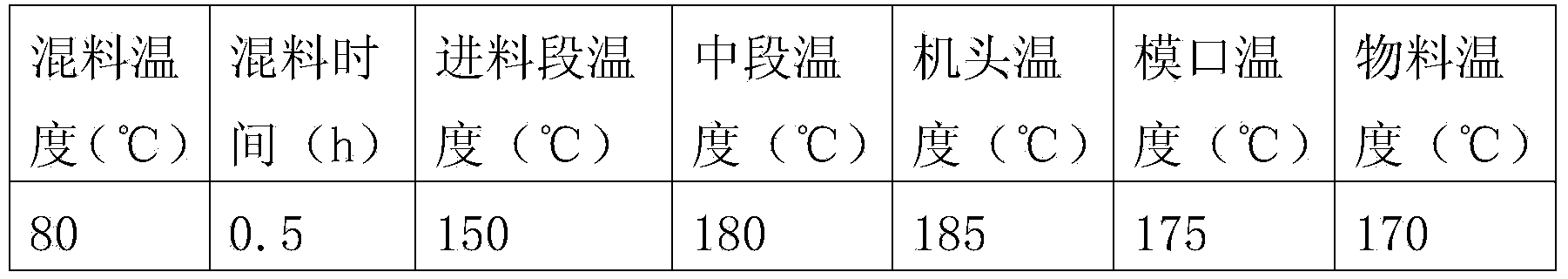

Embodiment 1

[0056] (1) The preparation method of the composite catalyst: Weigh 10 g of zinc acetate and 2 g of antimony trioxide in a 50 ml beaker, perform electromagnetic stirring at room temperature, mix evenly, and set aside.

[0057] (2) Esterification reaction: Add 1mol citric acid, 1mol n-butanol, 3mol octanol, 0.5mol cyclohexane into a 1000ml four-neck flask equipped with a temperature-controlled oil bath, agitator, water separator, and reflux condenser Heating to 30°C, stirring, until the citric acid is completely dissolved and mixed evenly with alcohol, take a sample to measure the initial acid value A of the reaction solution 0 , then add 6.7g of the composite catalyst prepared in step (1), heat to 100°C, and stir to generate reflux. When the water produced by the reaction begins to separate from the water separator, it is counted as the start time of the esterification reaction. When completely anhydrous is separated from the water separator, the reaction is considered to have...

Embodiment 2

[0063] (1) In the esterification reaction, add 1mol citric acid, 2mol n-butanol, 2mol octanol, 0.5mol hexamethylene and 6.2g compound catalyst prepared by step (1) in Example 1, other steps and conditions and implementation Example 1 is the same, and the esterification rate is 99.32%.

[0064] The modified citric acid ester of gained is checked through gas chromatography-mass chromatography, and its components are:

[0065] components

Embodiment 3

[0067] (1) In the esterification reaction, add 1mol citric acid, 3mol n-butanol, 1mol octanol, 0.5mol hexamethylene and 5.6g compound catalyst prepared by step (1) in Example 1, other steps and conditions and implementation Example 1 is the same, and the esterification rate is 99.12%.

[0068] The modified citric acid ester of gained is checked through gas chromatography-mass chromatography, and its components are:

[0069] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com