Water-based polyurethane color paint

A water-based polyurethane and color paint technology, applied in the field of coatings, can solve the problems of heavy pollution, high VOC emissions, high energy consumption, etc., and achieve the effects of good corrosion resistance, low irritation, and low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The base paint comprises the following components by weight: 50g of water-based polyurethane resin, 2g of water-based thickener, 0.3g of water-based defoamer, 0.7g of water-based wetting agent, 0.8g of water-based leveling agent, 4g of film-forming aid , water-based color paste 29g, deionized water 15g;

[0029] The consumption of described curing agent is 25.45g;

[0030] The consumption of described thinner is 30.56g;

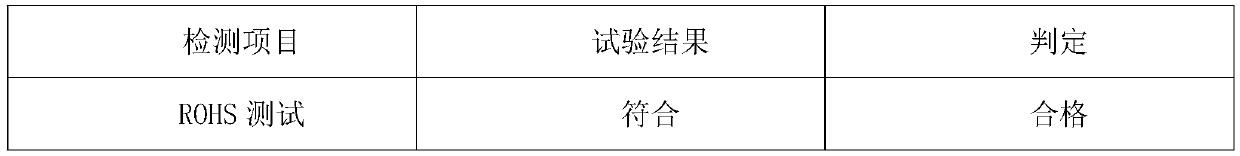

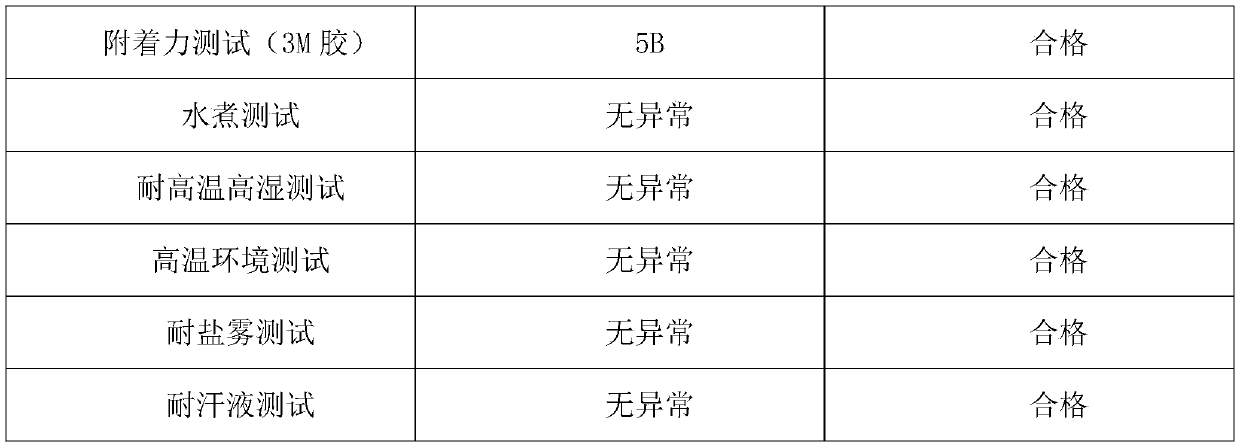

[0031] Add base paint and curing agent to the dispersing kettle to disperse evenly at a speed of 400 rpm, then slowly add diluent to continue dispersing, adjust the viscosity of the mixture in the dispersing kettle to 25-30S / 2# cup spray viscosity, and obtain water-based polyurethane For color paint, use water-based polyurethane color paint to spray several test samples. After spraying, place the workpiece in a flash dryer and bake at a temperature of 75°C for one hour, then take out the test sample and cool it to room temperature. Performance tests ...

Embodiment 2

[0035] The base paint comprises the following components by weight: 46g of water-based polyurethane resin, 2g of water-based thickener, 0.2g of water-based defoamer, 0.6g of water-based wetting agent, 0.7g of water-based leveling agent, 4g of film-forming aid , water-based color paste 25g, deionized water 15g;

[0036] The consumption of described curing agent is 23.375g;

[0037] The consumption of described thinner is 25.245g;

[0038] Add base paint and curing agent to the dispersing kettle to disperse evenly at a speed of 400 rpm, then slowly add diluent to continue dispersing, adjust the viscosity of the mixture in the dispersing kettle to 25-30S / 2# cup spray viscosity, and obtain water-based polyurethane For color paint, use water-based polyurethane color paint to spray several test samples. After spraying, place the workpiece in a flash dryer and bake at a temperature of 75°C for one hour, then take out the test sample and cool it to room temperature. Performance test...

Embodiment 3

[0041] The base paint comprises the following components by weight: 52g of water-based polyurethane resin, 2g of water-based thickener, 0.4g of water-based defoamer, 0.8g of water-based wetting agent, 0.8g of water-based leveling agent, and 4g of film-forming aid , water-based color paste 31g, deionized water 18g;

[0042] The consumption of described curing agent is 27.25g;

[0043] The consumption of described thinner is 34.88g;

[0044] Add base paint and curing agent to the dispersing kettle to disperse evenly at a speed of 400 rpm, then slowly add diluent to continue dispersing, adjust the viscosity of the mixture in the dispersing kettle to 25-30S / 2# cup spray viscosity, and obtain water-based polyurethane For color paint, use water-based polyurethane color paint to spray several test samples. After spraying, place the workpiece in a flash dryer and bake at a temperature of 75°C for one hour, then take out the test sample and cool it to room temperature. Performance te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com