Antifogging application of radiation curing composition

A technology of radiation curing and composition, applied in the application field of radiation curing composition in anti-fog, can solve the problems of affecting decoration or indication effect, fogging on the surface of printed products, etc., and achieve the effect of improving application performance and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 19-42

[0164] ①Use the pigment dispersion obtained in Examples 1-6 to prepare a color density of 50% k.

[0165]According to the formula shown in Table 5, under the condition of 20-30°C, pre-mix cationic polymerizable compounds B1, B2, cationic photoinitiator C, and sensitizer respectively, and then mix the raw materials according to B1, B2, C , sensitizer, pigment dispersion, leveling agent BYK307, and defoamer BYK055 are added to the constant temperature and pressure reactor in sequence, and the mixer is used at 1500-2000rpm under the condition of yellow light (that is, a safety light that will not trigger the reaction) Stir under low pressure, and when the mixed solution is a homogeneous mixture by visual inspection, filter through a 5 μm filter to obtain the radiation-curable composition of Examples 19-24 of the present invention.

[0166] table 5

[0167]

[0168] Table 5,

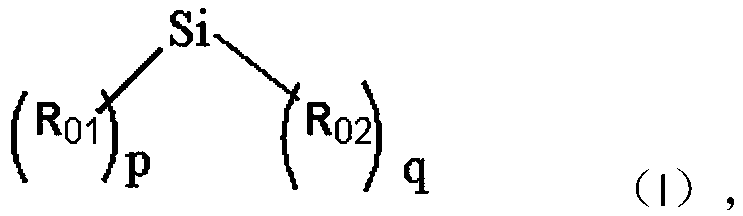

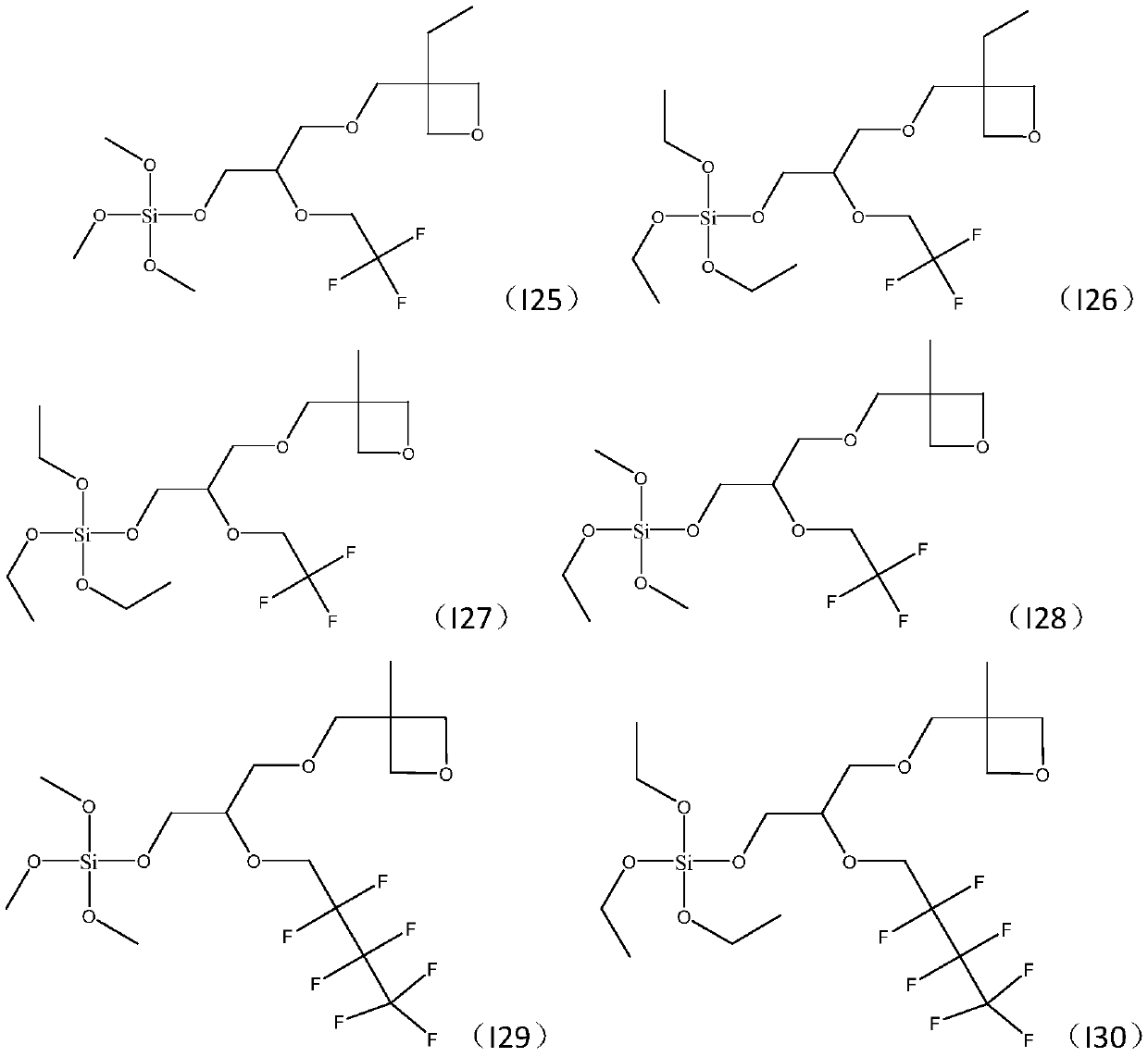

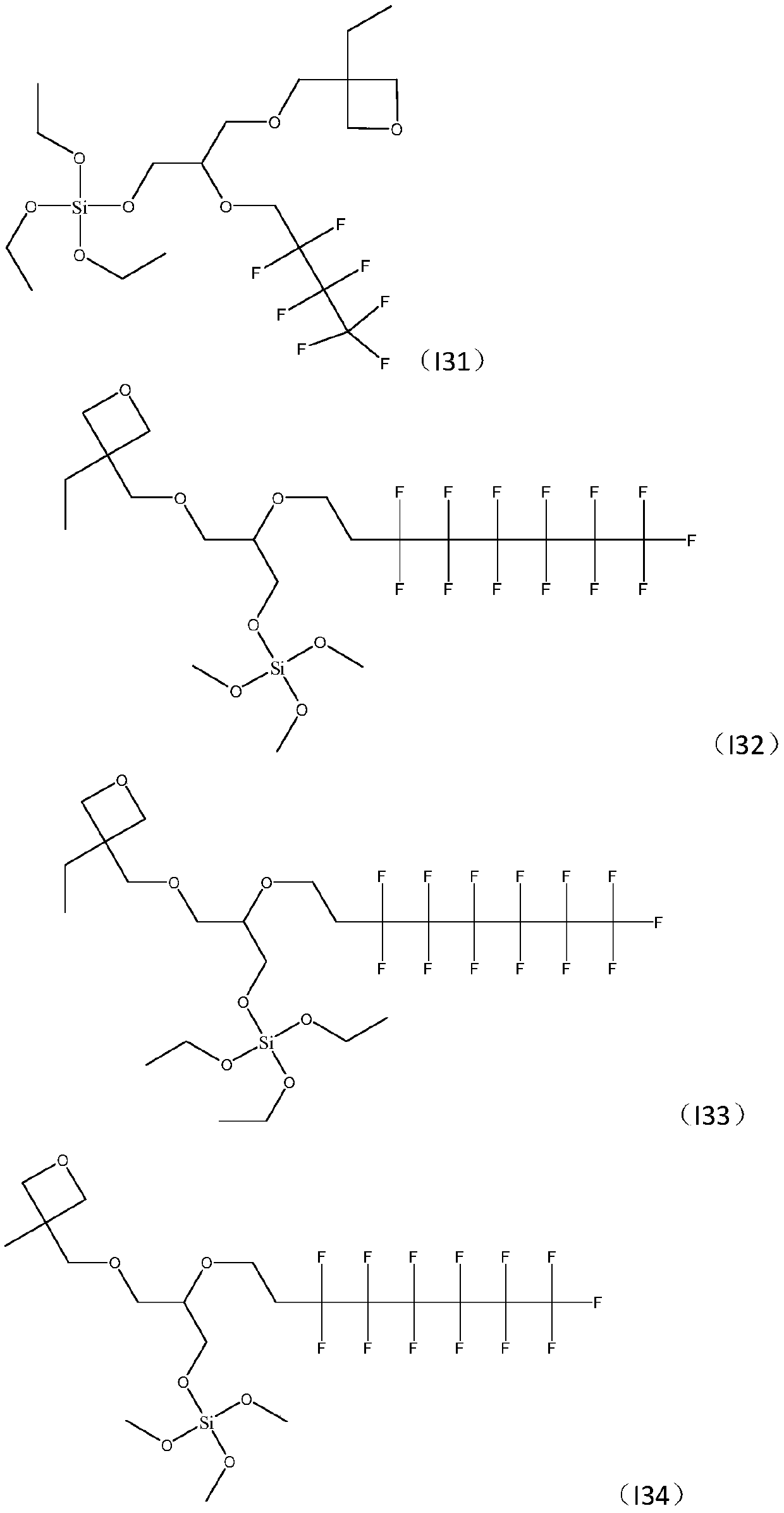

[0169] B11 is

[0170] B12 is:

[0171] B13 is decyl glycidyl ether XY747 of Anhui Xinyuan Che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com