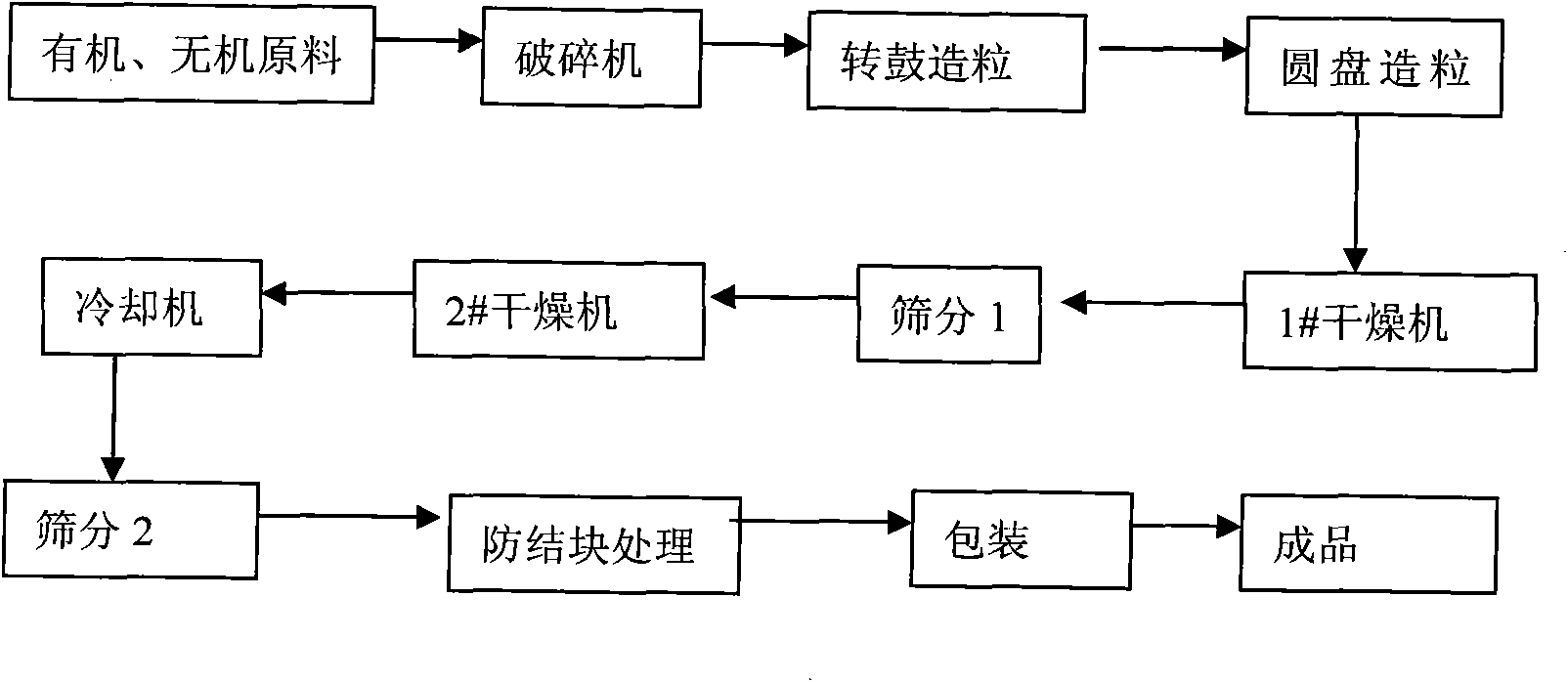

Production process of organic-inorganic compound fertilizer

A compound fertilizer and production process technology, applied in fertilizer forms, fertilizer mixtures, fertilization devices, etc., can solve the problems of yield decline, arable land quality decline, and high cost, achieve small return multiples, improve roundness, and form balls. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] As shown in the attached figure, the organic raw materials are fermented and become ecological organic fertilizers, which are measured separately with inorganic raw materials such as ammonium phosphate, general calcium, urea, and potassium chloride, and then enter the raw material conveying device. All raw materials should have good Physical properties and certain fineness; including organic raw materials, the raw materials entering the system are less than 1mm ≥ 60%; after passing through the crusher, the particle size of the material at the outlet of the crusher reaches: less than 2mm ≥ 95%; then enter the bucket elevator, and then be lifted by the bucket The machine is fed into the drum granulator, granulated by water, steam, and urine, and the material is formed in the granulator by the rotation of the body to form a fluidized bed of mechanical solid materials. During the flow of materials, extrusion and friction Under the action of the drum granulator, it will be ag...

Embodiment 2

[0032] In this embodiment, the granulation temperature is 40°C, the moisture content of the granulated material is controlled at 10%, and the drying temperature is controlled at 60°C. Other steps are identical with embodiment 1.

Embodiment 3

[0034] In this embodiment, the granulation temperature is 60°C, the moisture content of the granulation material is controlled at 5%, and the drying temperature is controlled at 80°C. Other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com