Three-dimensional printer with automatic clearing function

A 3D printer and automatic cleaning technology, applied in the direction of additive processing, etc., can solve the problems of easy residue of materials, clogging of printing nozzles and feeding hoses, printer damage, etc., to avoid condensation and print smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

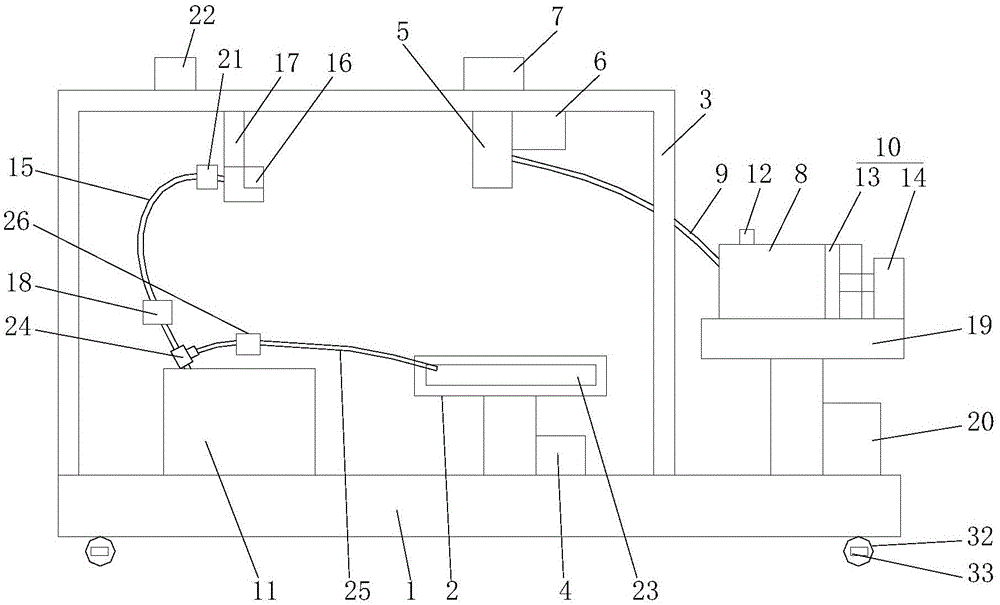

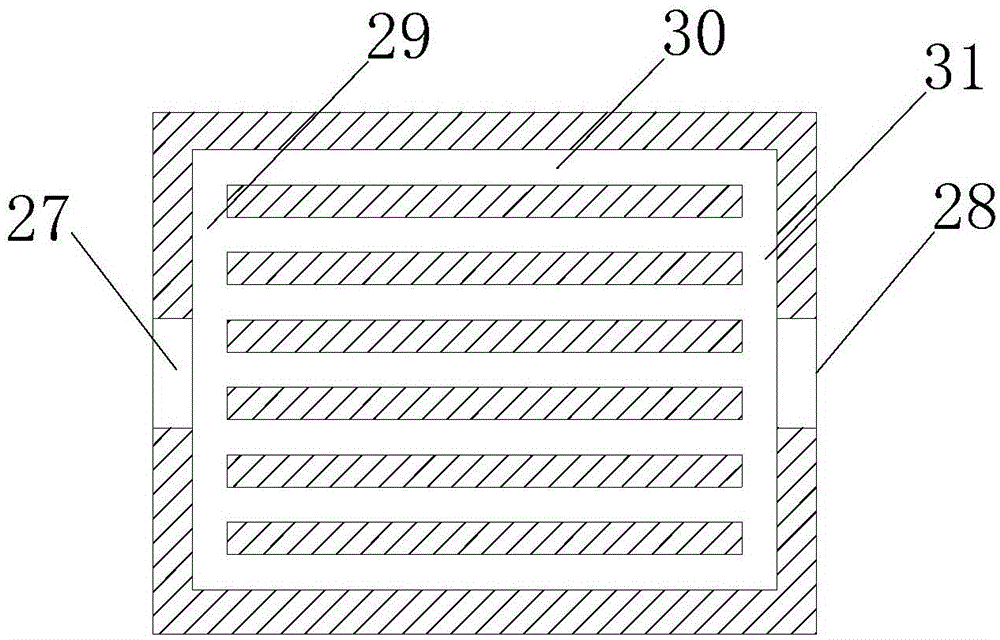

[0023] Such as figure 1 , figure 2 as shown, figure 1 It is a structural schematic diagram of a three-dimensional printer with automatic cleaning function proposed by the present invention; figure 2 It is a schematic structural diagram of a cooling cavity in a three-dimensional printer with automatic cleaning function proposed by the present invention.

[0024] refer to figure 1 , a three-dimensional printer with an automatic cleaning function proposed by the present invention, including a base 1, a first workbench 2, a support frame 3, a first drive mechanism 4, a printing nozzle 5, a third drive mechanism 6, and a fourth drive mechanism 7 , storage box 8, feeding pipe 9, feeding device 10, blower 11 and controller;

[0025] The first workbench 2, the support frame 3 and the blower 11 are respectively arranged on the base 1, the first workbench 2 is a liftable workbench, the first workbench 2 is connected with the first driving mechanism 4, and is driven by it along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com