Microfluidic chip and droplet generation device applying same

A technology for a microfluidic chip and a generating device, applied in the field of microfluidics, can solve the problems of inability to widely use microfluidic microdroplet chip preparation, large microchannel size, large microdroplet size, etc. The effect of maintenance, cost reduction and business value enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

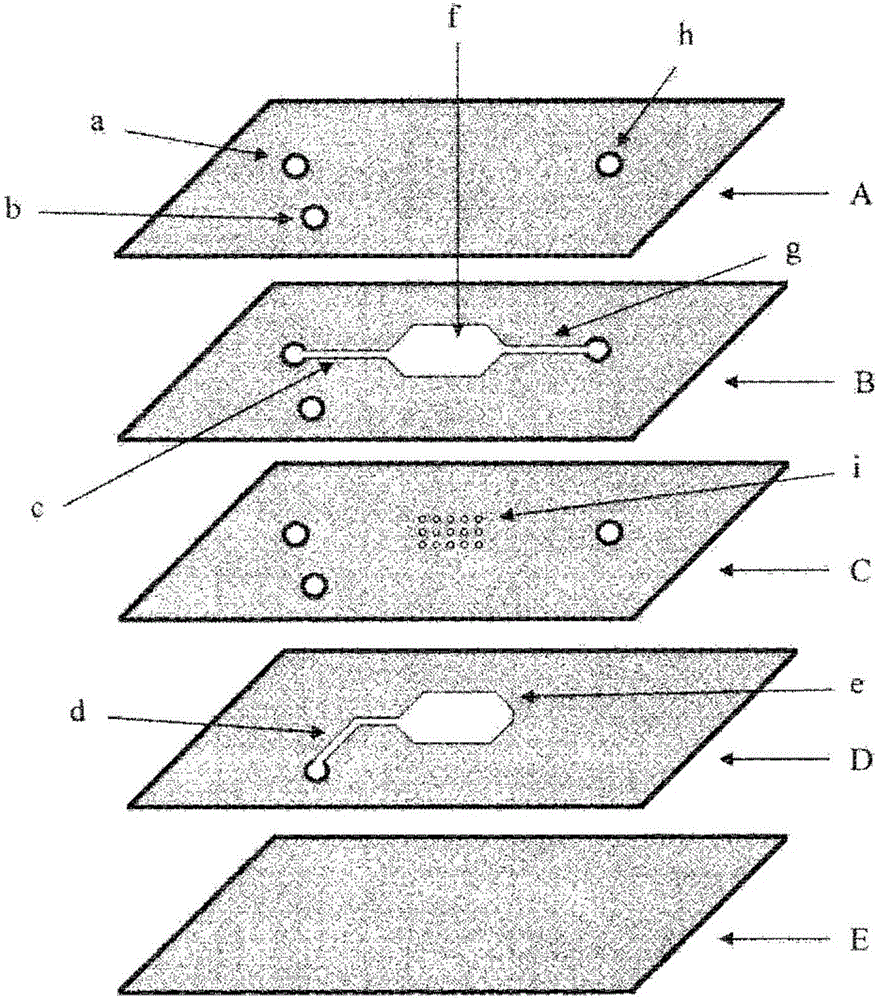

[0035] The inventive idea of the present invention is to provide a microfluidic chip with a three-dimensional structure, which can produce relatively small micro-droplets, and which can be formed by stereolithography appearance (SLA) in 3D printing technology. To prepare, so as to achieve simple and convenient, low-cost production and easy maintenance.

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0037] 1. Microfluidic chip

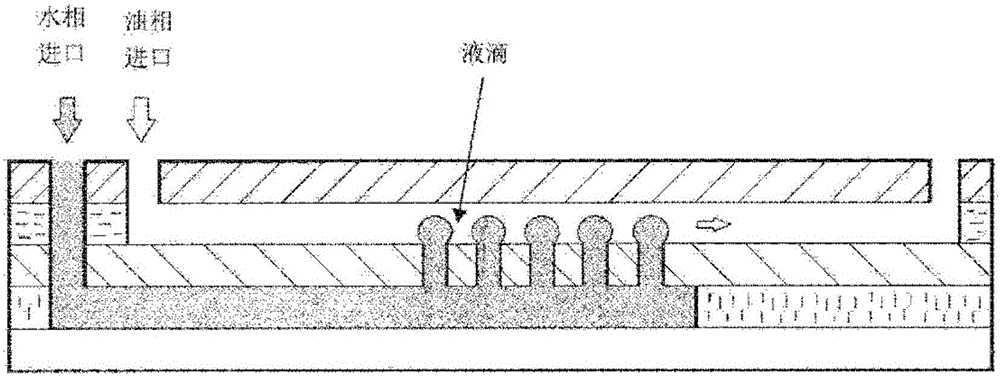

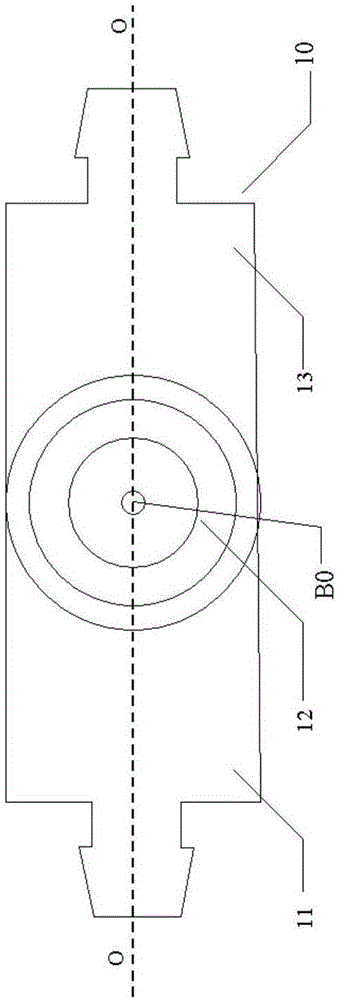

[0038] In a first exemplary embodiment of the present invention, a microfluidic chip is provided. Figure 3A , Figure 3B , Figure 3C with Figure 3D They are respectively a top view, a left view, a front view and a right view of a microfluidic chip according to an embodiment of the present invention. Figure 4 for Figure 3A ~ Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com