Processing method for enhancing ageing resistance of bamboo battens

A processing method and anti-aging technology, applied in wood processing equipment, plant material machining, manufacturing tools, etc., can solve the problems of easy mold deformation, easy aging, and affecting the toughness of bamboo strips, so as to improve the boiling water resistance and Good effect of aging resistance, stability improvement, bending strength and rigidity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

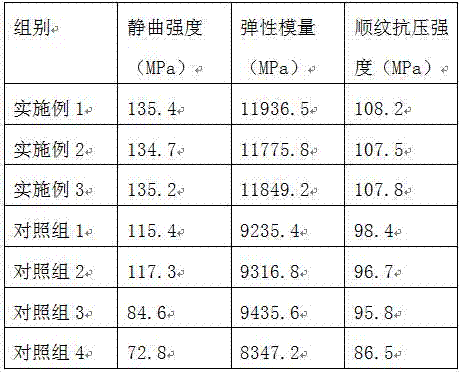

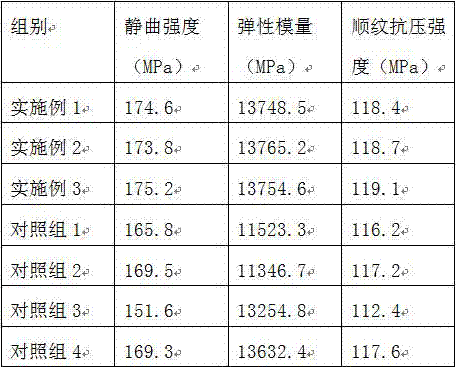

Examples

Embodiment 1

[0015] A processing method for enhancing the aging resistance of bamboo strips, the steps of which include cutting raw bamboo, splitting, steaming and pretreatment, cutting strips, primary drying, dipping, secondary drying, forming blanks, pressing, stacking, sawing edges, planing, four-sided planing, painting, inspection, packaging, and storage; the specific content of the cooking and pretreatment is: put the pepper stalks and bamboo chips at a temperature of 70-75°C and a mass concentration of 5-8‰ Boil in sodium hydroxide solution for 6-8 hours, the weight ratio of the pepper stalks, paulownia and bamboo chips is 1:6:14, then steam in steam at 110-120°C for 2-3 hours, and then cook the boiled Bamboo slices are carbonized in a carbonization machine, the carbonization temperature is 125°C, the humidity is 80-85%, and the time is 2.5-4 hours;

[0016] The condition of the first drying is to dry to a moisture content of 40% under low-power microwave conditions, and the microwav...

Embodiment 2

[0020] A processing method for enhancing the aging resistance of bamboo strips, the steps of which include cutting raw bamboo, splitting, steaming and pretreatment, cutting strips, primary drying, dipping, secondary drying, forming blanks, pressing, stacking, sawing edges, planing, four-sided planing, painting, inspection, packaging, and storage; the specific content of the cooking and pretreatment is: put the pepper stalks and bamboo chips at a temperature of 70-75°C and a mass concentration of 5-8‰ Boil in sodium hydroxide solution for 6-8 hours, the weight ratio of the pepper stalks, paulownia and bamboo chips is 1:5:14, then steam in steam at 110-120°C for 2-3 hours, and then boil the boiled The bamboo chips are carbonized in a carbonization machine, the carbonization temperature is 135°C, the humidity is 80%, and the time is 3 hours;

[0021] The condition of the first drying is to dry to a moisture content of 38% under low-power microwave conditions, and the microwave po...

Embodiment 3

[0025] A processing method for enhancing the aging resistance of bamboo strips, the steps of which include cutting raw bamboo, splitting, steaming and pretreatment, cutting strips, primary drying, dipping, secondary drying, forming blanks, pressing, stacking, sawing edges, planing, four-sided planing, painting, inspection, packaging, and storage; the specific content of the cooking and pretreatment is: put the pepper stalks and bamboo chips at a temperature of 70-75°C and a mass concentration of 5-8‰ Boil in sodium hydroxide solution for 6-8 hours, the weight ratio of the pepper stalks, paulownia and bamboo chips is 1:7:14, then steam in steam at 110-120°C for 2-3 hours, and then boil the boiled The bamboo chips are carbonized in the carbonization machine, the carbonization temperature is 110-135°C, the humidity is 80-85%, and the time is 2.5-4 hours;

[0026] The conditions for the primary drying are to dry to a moisture content of 40% under low-power microwave conditions, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com