Waterproof reinforcing agent for urea-formaldehyde adhesive for boiling-resistant artificial board

A reinforcing agent, board urea-formaldehyde technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of large amount of melamine, high cost, high cost, etc., to improve heat resistance and Waterproof performance, cost saving, and strength improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

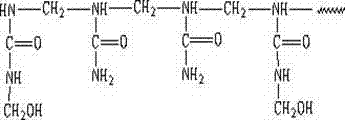

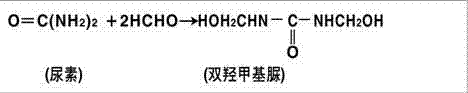

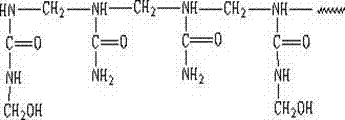

Method used

Image

Examples

Embodiment 1

[0056] In terms of mass percentage, the boiling-resistant artificial board urea-formaldehyde glue waterproof enhancer consists of the following components:

[0057] Aluminum Sulfate 30%

[0059] Stearic Acid 20%

[0060] Potassium dichromate 5%

[0061] Aluminum silicate 20%

[0062] 1,2,3-Triphenylcyclopropane 5%

[0063] The specific glue-making process of using the boiling-resistant wood-based panel urea-formaldehyde glue waterproof enhancer of the present invention is:

[0064] 2 glue making process

[0065] (1) Add 1000kg of formaldehyde solution with a mass concentration of 37% into the kettle, add 12kg of the water-proof enhancer of urea-formaldehyde glue for the boiling-resistant wood-based panel, and then stir for 30 minutes to completely dissolve the water-proof enhancer of the urea-formaldehyde glue for the boil-resistant wood-based panel. Adjust the pH value to 7.5 with sodium, then add 350 kg of urea solution with a mass concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com