Exterior-covered waterproof construction method for subway station side walls with hanging plate girders

A technology for subway stations and construction methods, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as lack of experience, and achieve the effects of comprehensive consideration, strong adaptability and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

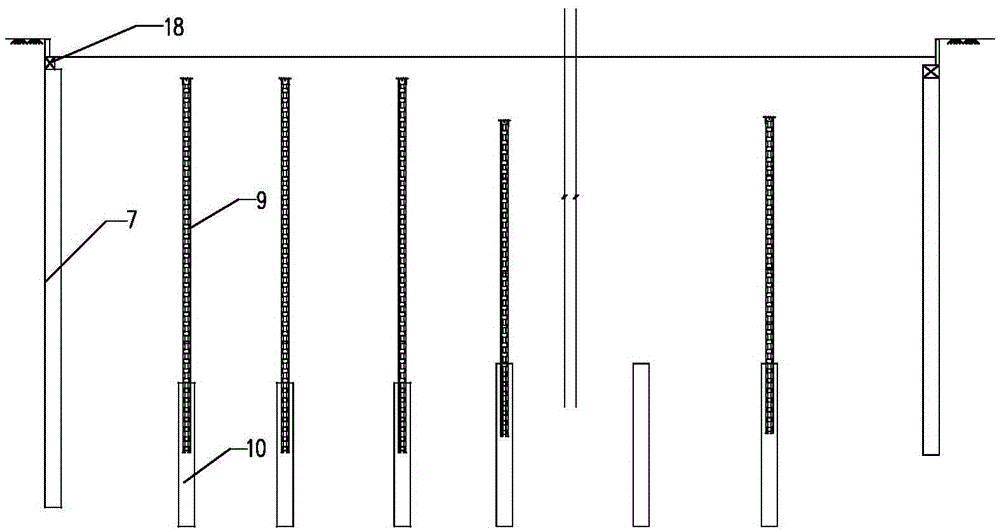

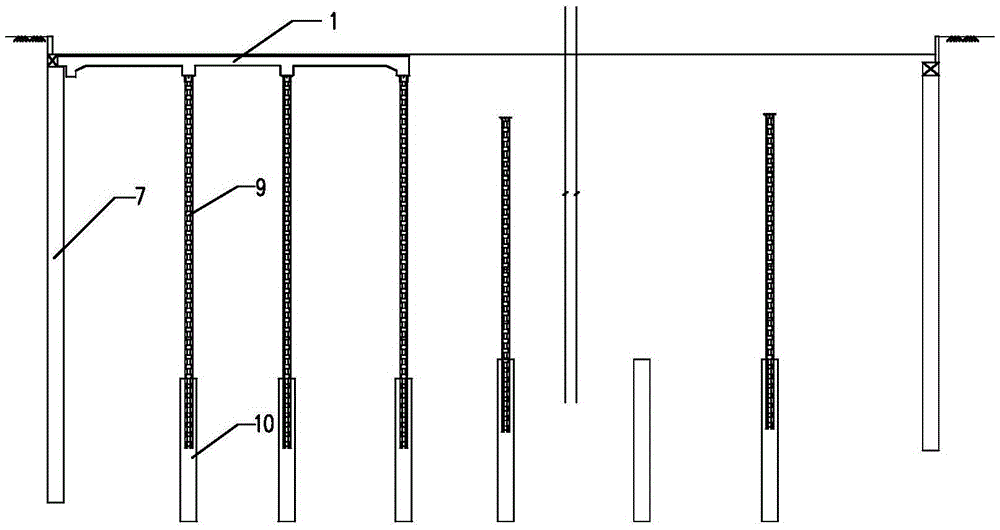

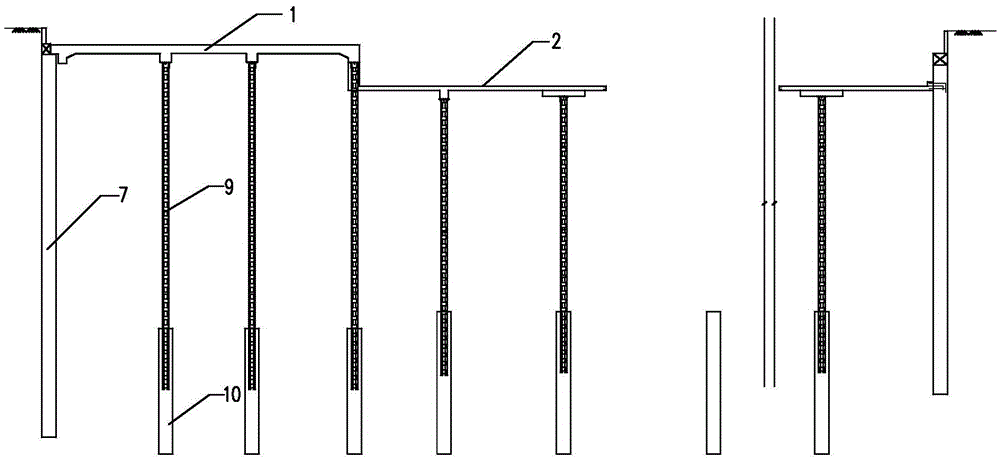

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. Figure 1 to Figure 8 The embodiment described in is a construction drawing of a subway station of Tianjin Metro Line 6. The construction site includes a station, two shield sections and an open-cut section, wherein Minquanmen station and China Railway Construction International City 1D plot The basement of Shijing Plaza is constructed to form a large foundation pit. The total area of the foundation pit is 19,100m2 (including 3,560m2 for the subway and 15,540m2 for the plot), and the earthwork volume is about 400,000m3. The maximum span is 160m, and the average span is 140m. The station adopts cover-excavation method for construction. The overall structure of the construction is as follows: Figure 1 to Figure 3 As shown, including the roof of the subway station, the roof of the commercial real estate, the middle slab of the two-story subway station, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com