High-performance flame-retardant antistatic powder coating and preparation method thereof

A flame retardant, antistatic, powder coating technology, applied in powder coatings, conductive coatings, anti-corrosion coatings, etc., can solve difficult flame retardant, weather resistance, acid and alkali corrosion resistance, single function, difficult to obtain high-performance coatings And other problems, to achieve the effect of smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

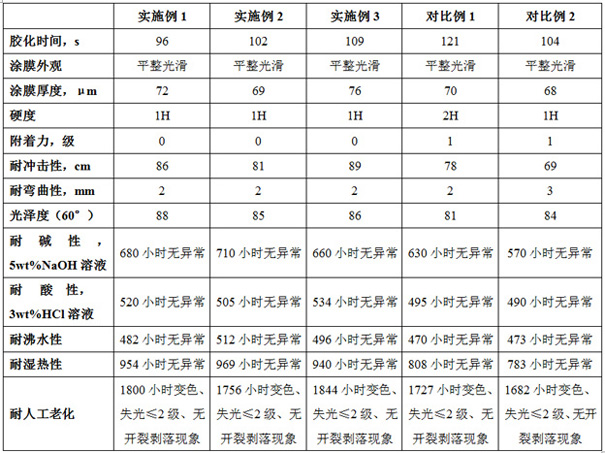

Embodiment 1

[0071] Example 1: A high-performance flame-retardant antistatic powder coating and its preparation method

[0072] Include the following steps:

[0073] 1. Flame retardant and antistatic powder coating

[0074] The concrete formula of coating comprises by weight:

[0075] 210 parts epoxy resin

[0076] 40 parts antistatic hyperbranched polyester

[0077] 30 parts high flame retardant curing agent

[0078] 0.5 part curing accelerator

[0079] 1 part leveling agent

[0080] 1.5 parts degasser

[0081] 25 parts of pigments and fillers

[0082] Described epoxy resin is bisphenol A type epoxy resin;

[0083] The curing accelerator is ethyltriphenylphosphine bromide;

[0084] The leveling agent is cellulose acetate butyrate;

[0085] The degassing agent is 2-hydroxyl-2-phenylacetophenone;

[0086] The pigment and filler are titanium dioxide;

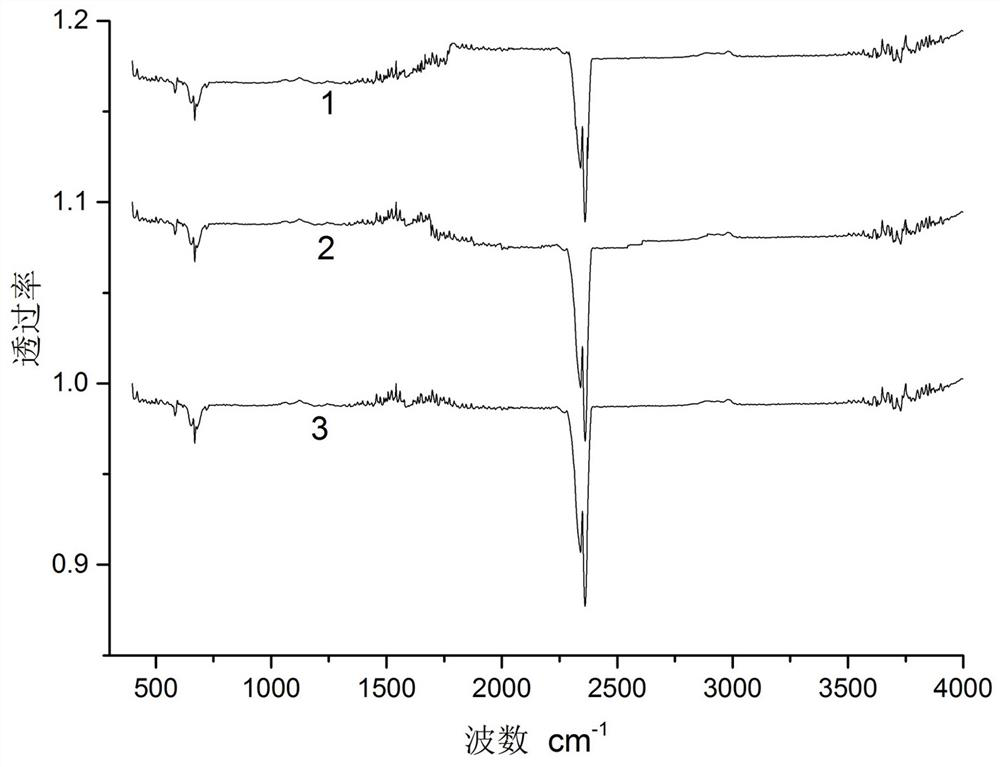

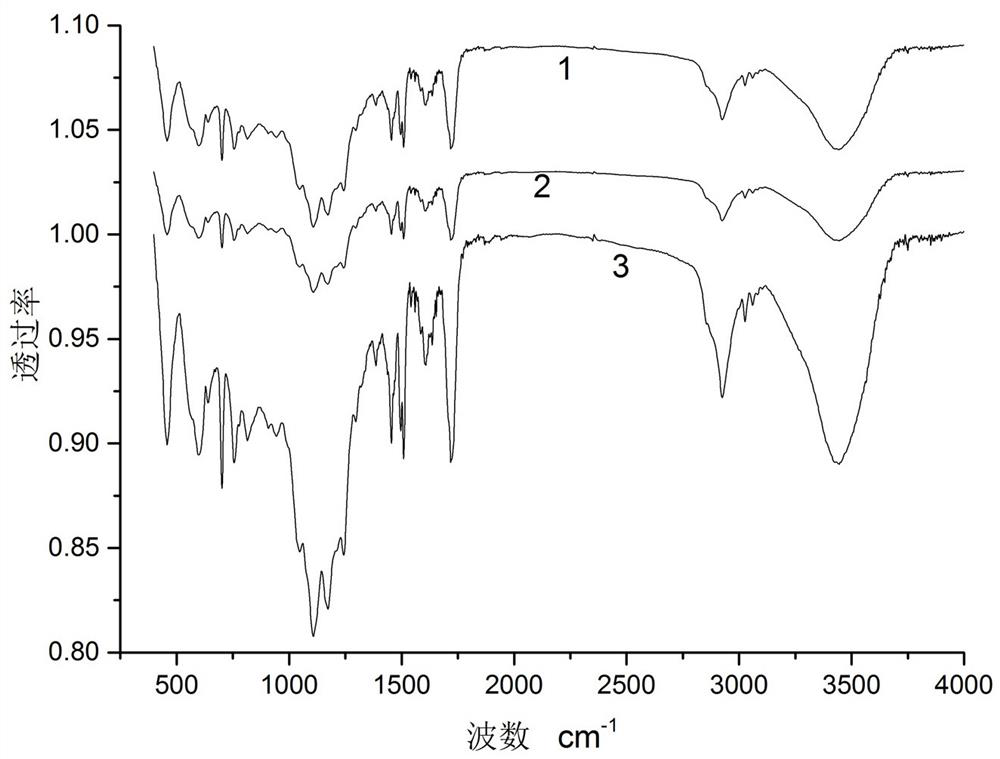

[0087] (1) Synthesis of high flame retardant curing agent

[0088] 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, bromohydr...

Embodiment 2

[0120] Example 2: A high-performance flame-retardant antistatic powder coating and its preparation method

[0121] Include the following steps:

[0122] 1. Flame retardant and antistatic powder coating

[0123] The concrete formula of coating comprises by weight:

[0124] 180 parts epoxy resin

[0125] 20 parts antistatic hyperbranched polyester

[0126] 15 parts high flame retardant curing agent

[0127] 0.2 part curing accelerator

[0128] 0.5 part leveling agent

[0129] 1 part degasser

[0130] 10 parts pigments and fillers

[0131] Described epoxy resin is bisphenol A type epoxy resin;

[0132] The curing accelerator is ethyltriphenylphosphine bromide;

[0133] The leveling agent is cellulose acetate butyrate;

[0134] The degassing agent is 2-hydroxyl-2-phenylacetophenone;

[0135] The pigment and filler are barium sulfate;

[0136] (1) Synthesis of high flame retardant curing agent

[0137] 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, bromohydroxybenza...

Embodiment 3

[0170] Example 3: A high-performance flame-retardant antistatic powder coating and its preparation method

[0171] Include the following steps:

[0172] 1. Flame retardant and antistatic powder coating

[0173] The concrete formula of coating comprises by weight:

[0174] 230 parts epoxy resin

[0175] 50 parts antistatic hyperbranched polyester

[0176] 45 parts of high flame retardant curing agent

[0177] 0.8 parts curing accelerator

[0178] 2 parts leveling agent

[0179] 3 parts degasser

[0180] 35 parts of pigments and fillers

[0181] Described epoxy resin is bisphenol A type epoxy resin;

[0182] The curing accelerator is ethyltriphenylphosphine bromide;

[0183] The leveling agent is cellulose acetate butyrate;

[0184] The degassing agent is 2-hydroxyl-2-phenylacetophenone;

[0185] The pigment and filler are a mixture of titanium dioxide and barium sulfate with a mass ratio of 1:1;

[0186] (1) Synthesis of high flame retardant curing agent

[0187] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com