Integrated material wood-splicing adhesive and preparation method thereof

A technology of splicing glue and laminated material, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, etc., can solve the problems of heat resistance, water resistance, poor water resistance and heat resistance, etc. Boiling water resistance, improved flexibility, improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

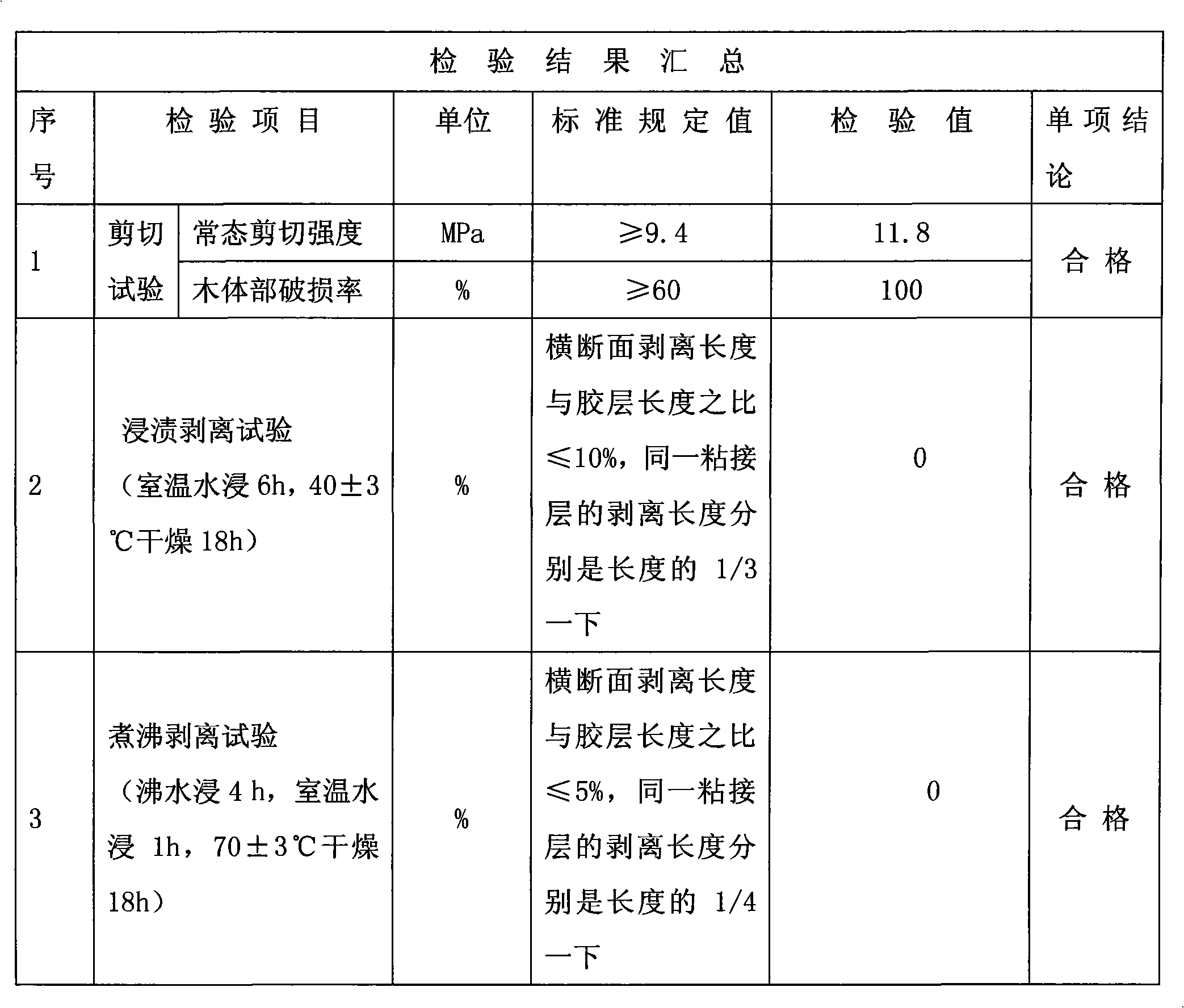

Embodiment 1

[0042] A glulam glue is prepared from 100 parts by weight of a main agent and 13 parts by weight of a crosslinking agent-modified polyisocyanate, and the main agent and the crosslinking agent are packaged separately. The main ingredient is prepared from the following raw materials in weight percent:

[0043] Polyvinyl Alcohol 3%,

[0044] Vinyl acetate 38.92%,

[0045] Acrylic 1%,

[0046] Butyl Acrylate 5%,

[0047] Methacrylic acid 1%,

[0048] Hydroxyethyl Acrylate 0.9%,

[0049] Emulsifier OP-101%,

[0050] Sodium Lauryl Sulfate 1%,

[0051] Ammonium persulfate 0.08%,

[0052] Anhydrous sodium acetate 0.1%,

[0053] Deionized Water 48%.

[0054] The modified polyisocyanate adopts DESMODUR44V20L brand product produced by Bayer Company, which is a compound based on diphenylmethane diisocyanate, with an NCO weight percentage ≥ 30%, and a viscosity of 170-270mpas at 25°C. The polyvinyl alcohol adopts the 2088 brand product produced by Sichuan Vinylon Company, the deg...

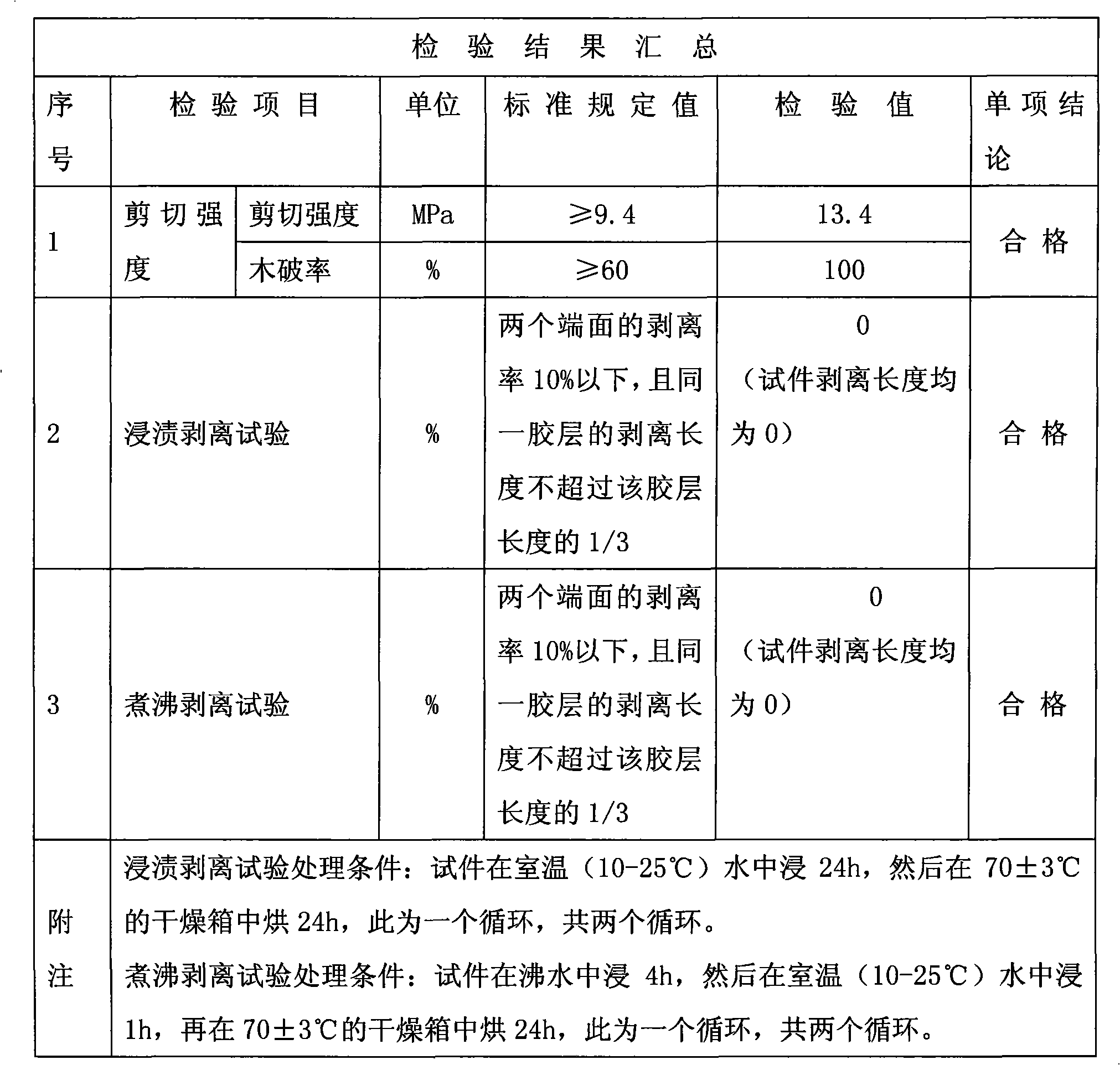

Embodiment 2

[0063] A glulam glue is prepared from 100 parts by weight of a main agent and 17 parts by weight of a crosslinking agent-modified polyisocyanate, and the main agent and the crosslinking agent are packaged separately. The main ingredient is prepared from the following raw materials in weight percent:

[0064] Polyvinyl Alcohol 5%,

[0065] Vinyl acetate 21.4%,

[0066] Acrylic 3%,

[0067] Butyl Acrylate 10%,

[0068] Methacrylic acid 3%,

[0069] Hydroxyethyl Acrylate 1.1%,

[0070] Emulsifier OP-102%,

[0071] Sodium Lauryl Sulfate 2%,

[0072] Ammonium persulfate 0.2%,

[0073] Anhydrous sodium acetate 0.3%,

[0074] Deionized water 52%.

[0075] The modified polyisocyanate adopts DESMODUR44V20L brand product produced by Bayer Company, which is a compound based on diphenylmethane diisocyanate, with an NCO weight percentage ≥ 30%, and a viscosity of 170-270mpas at 25°C. The polyvinyl alcohol adopts the 1788 brand product produced by Sichuan Vinylon Company, the degr...

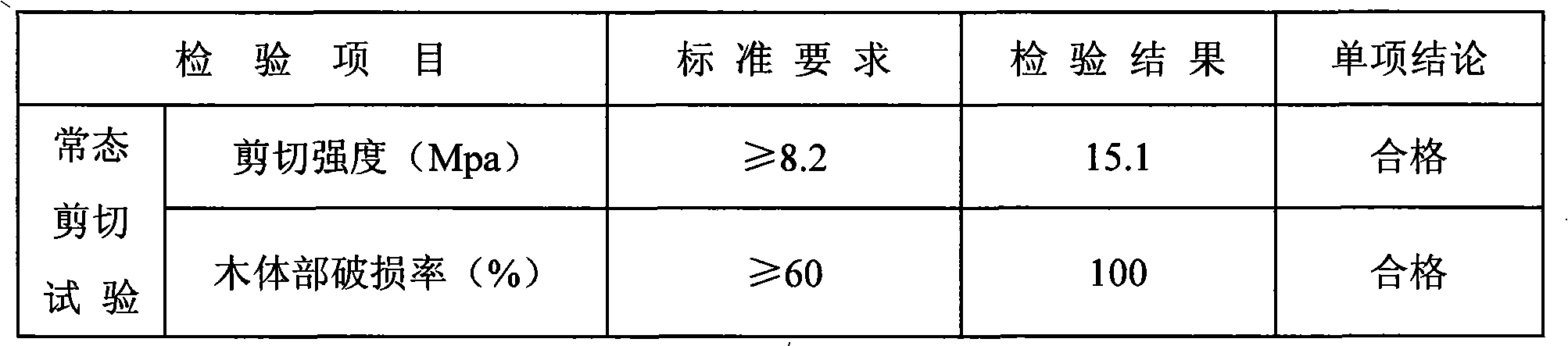

Embodiment 3

[0084] A glulam glue is prepared from 100 parts by weight of a main agent and 15 parts by weight of a crosslinking agent-modified polyisocyanate, and the main agent and the crosslinking agent are packaged separately. The main ingredient is prepared from the following raw materials in weight percentage:

[0085] Polyvinyl Alcohol 4%,

[0086] Vinyl acetate 30.2%,

[0087] Acrylic 2%,

[0088] Butyl Acrylate 7.5%,

[0089] Methacrylic acid 2%,

[0090] Hydroxyethyl Acrylate 1%,

[0091] Emulsifier OP-101.5%,

[0092] Sodium Lauryl Sulfate 1.5%,

[0093] Ammonium persulfate 0.1%,

[0094] Anhydrous sodium acetate 0.2%,

[0095] Deionized water 50%.

[0096] The modified polyisocyanate adopts DESMODUR44V20L brand product produced by Bayer Company, which is a compound based on diphenylmethane diisocyanate, with an NCO weight percentage ≥ 30%, and a viscosity of 170-270mpas at 25°C. The polyvinyl alcohol adopts the 1788 brand product produced by Sichuan Vinylon Company, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com