Silicon-titanium hybrid acrylate polymer and double-cured paint prepared therefrom

An acrylate and acrylate-based technology, applied in the field of dual-cure coatings, can solve the problems of reduced coating transparency, unfavorable resin stability, poor storage stability, etc., to achieve improved adhesion, excellent continuous anti-fog and boiling water resistance , good anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

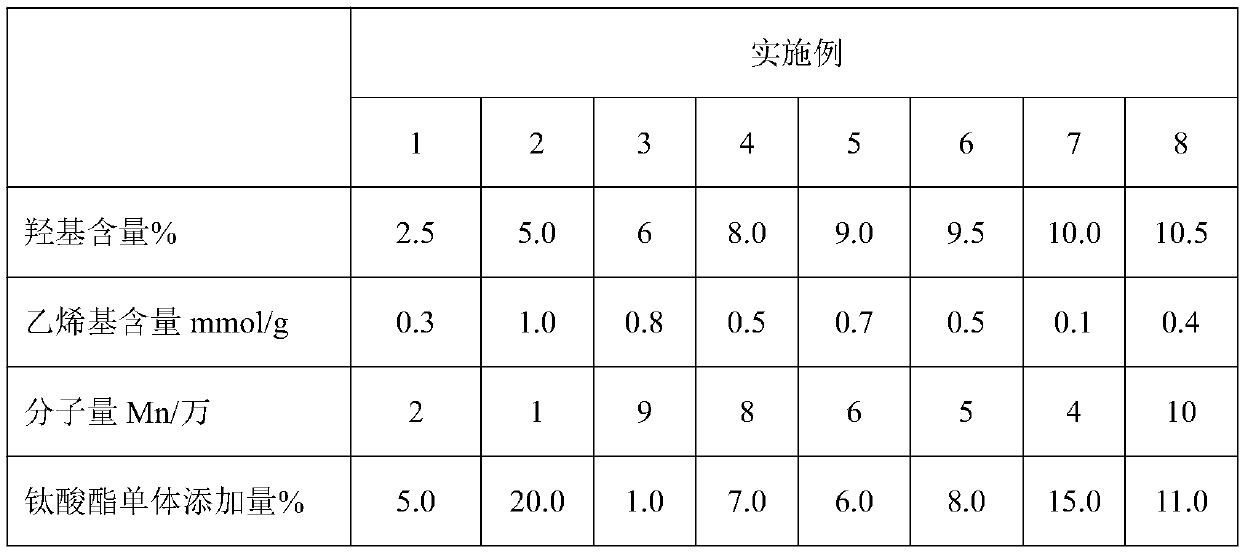

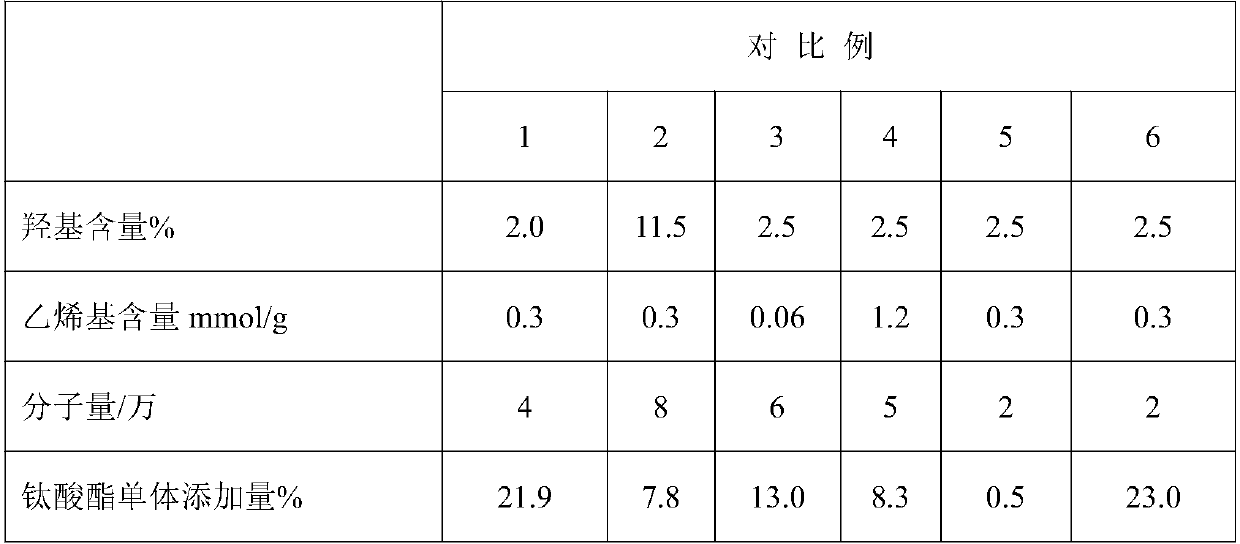

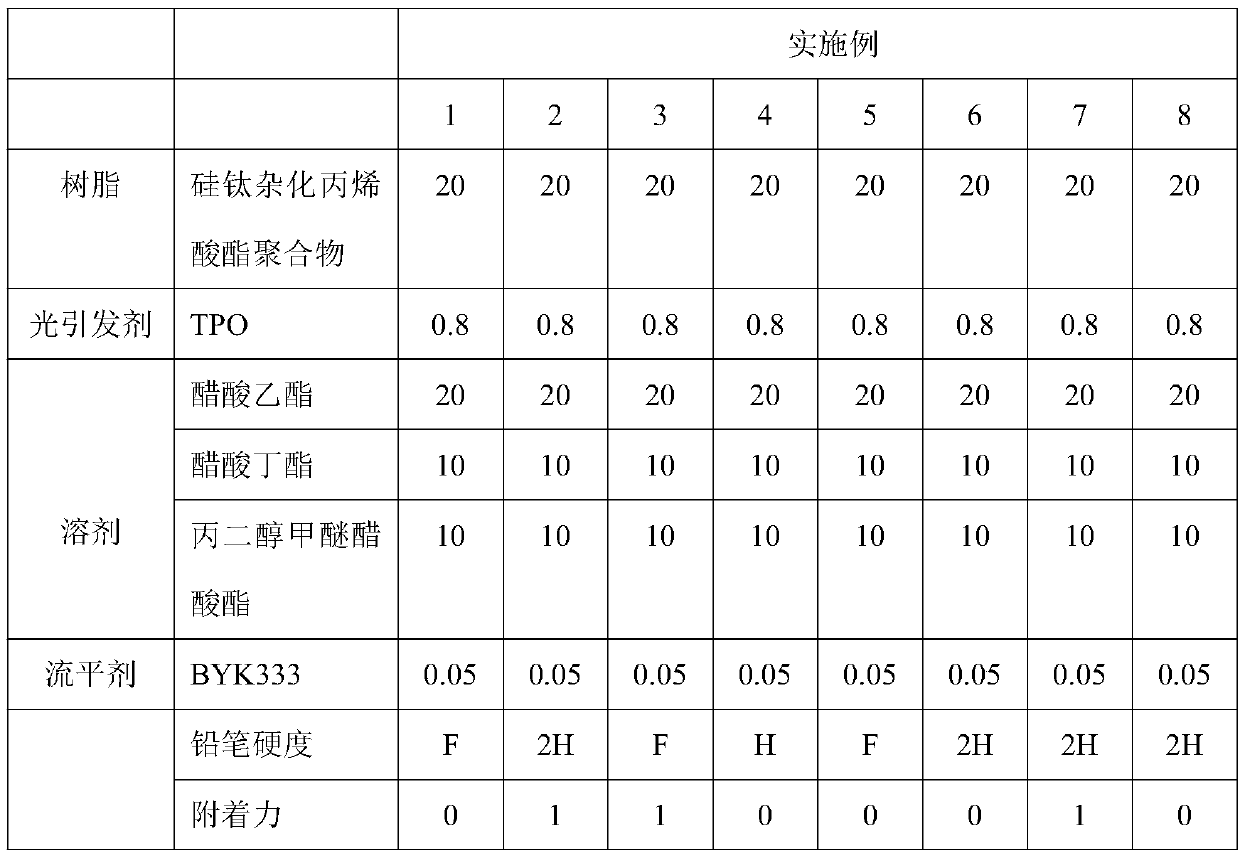

Examples

Embodiment 1

[0026] 1. Mix 13.7g butyl acrylate, 19.5g isooctyl acrylate, 15.4g decyl acrylate, 15g methacryloxypropyltrimethoxysilane, 10g vinyltrimethoxysilane, 75.9g polycaprolactone Modified acrylate (molecular weight 344), 36.7g polyethylene glycol acrylate (molecular weight 500), 4.3g acrylic acid, 1g1,1-bis(tert-amylperoxy)cyclohexane is prepared into a mixed solution for subsequent use;

[0027] 2. Protect the reactor equipped with agitator, condenser, and peristaltic pump with nitrogen gas, and preheat to 105°C at the same time; after reaching the preheating temperature, slowly add the mixed solution into the reactor through the peristaltic pump for about 3 hours Complete; after 105 ° C for 4 hours, weigh 0.2 g of p-hydroxyanisole (MEHQ) and 2 g of triphenylphosphine (TPP), stir evenly, add 8.5 g of glycidyl methacrylate, and continue to heat for 4 hours to obtain organosilicone Acrylate prepolymers.

[0028] 3. After cooling the system to room temperature, add 6g of tetraisopropyl...

Embodiment 2

[0030] 1. Mix 18.7g isooctyl methacrylate, 20g decyl acrylate, 26g vinyltriethoxysilane, 69g hydroxyethyl methacrylate, 20g polycaprolactone modified acrylate (molecular weight 344), 6g acrylic acid , 10.1g methacrylic acid, 1g tert-butyl peroxide 2-ethylhexanoate, 0.7g 1,1-bis(tert-amylperoxy)cyclohexane are prepared into a mixed solution for subsequent use;

[0031] 2. Protect the reactor equipped with agitator, condenser, and peristaltic pump with nitrogen, and preheat to 105°C at the same time; after reaching the preheating temperature, slowly add the mixed solution into the reactor through the peristaltic pump, about 3 hours After 4 hours of heat preservation at 105°C, weigh 0.2g of MEHQ and 2g of TPP, stir evenly, add 28.5g of glycidyl methacrylate, and continue to heat for 4 hours to obtain a silicone hybrid acrylate prepolymer.

[0032] 3. After cooling the system to room temperature, add 35g tetraisopropyl bis(dioctylphosphite acyloxy) titanate and 15.1g diisopropyl b...

Embodiment 3

[0034] 1. Mix 19.4g isooctyl acrylate, 12.3g lauryl methacrylate, 15.4g methacryloxypropyltriethoxysilane, 13g vinyltrimethoxysilane, 101.8g hydroxybutyl acrylate, 13.8 1g of methacrylic acid, 0.5g of 2-ethylhexanoic acid tert-butyl peroxide and 1g of 1,1-bis(tert-amylperoxy)cyclohexane are prepared into a mixed solution for subsequent use;

[0035] 2. Protect the reactor equipped with agitator, condenser, and peristaltic pump with nitrogen, and preheat to 105°C at the same time; after reaching the preheating temperature, slowly add the mixed solution into the reactor through the peristaltic pump, about 3 hours After 4 hours of heat preservation at 105°C, weigh 0.2g of MEHQ and 2g of TPP, stir evenly, add 22.8g of glycidyl methacrylate, and continue to heat for 4 hours to obtain a silicone hybrid acrylate prepolymer.

[0036] 3. After cooling the system down to room temperature, add 2g of tetraisopropyl titanate, and stir evenly at room temperature with a humidity not greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com