Preparation method of furan-modified cashew phenolic resin

A technology of cardanol phenolic resin and cardanol, which is applied in the preparation field of furan-modified cardanol phenolic resin, can solve the problems that the boiling water resistance cannot meet the application requirements, and achieves excellent boiling water resistance, improved boiling water resistance, and superior heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

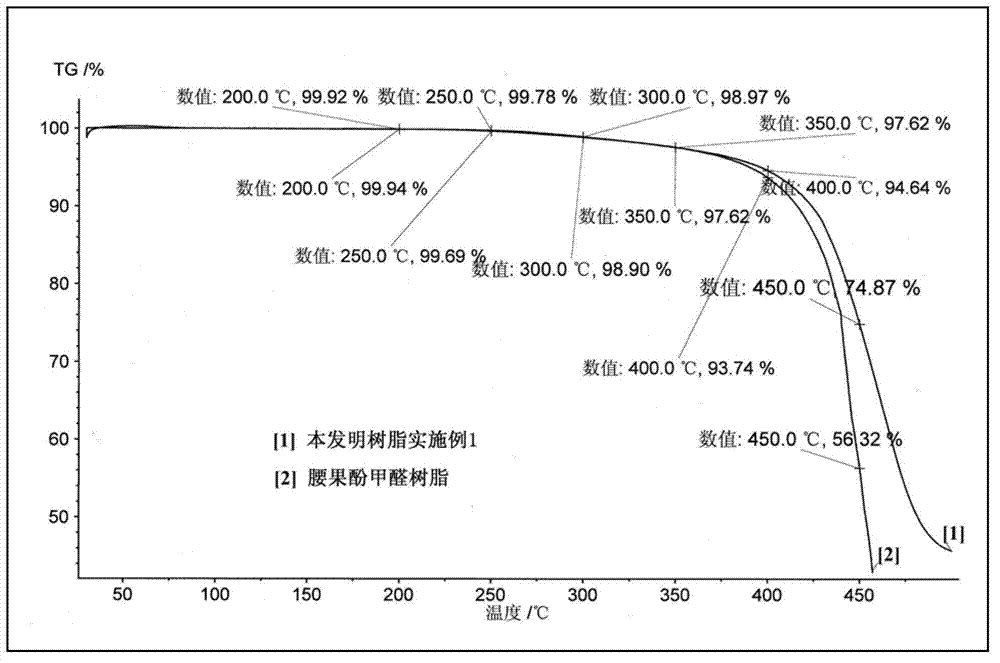

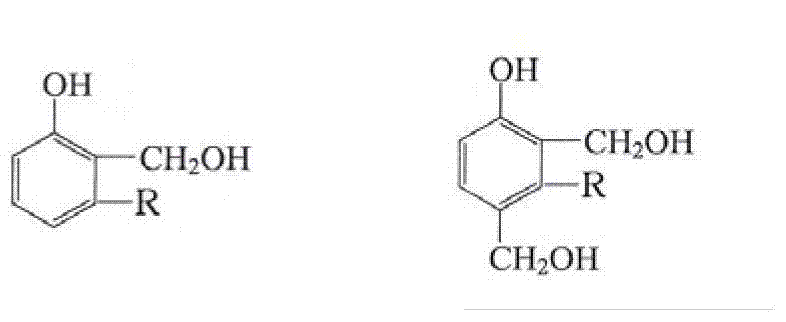

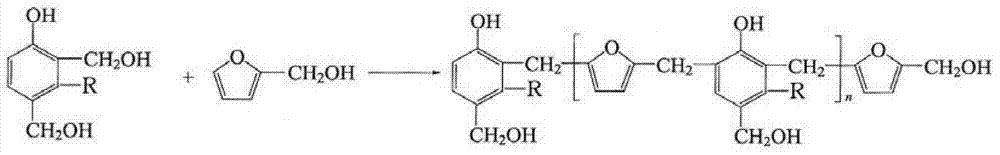

[0015] The design concept of the preparation method of the furan-modified cashew phenolic resin of the present invention is based on the fact that the furan ring of the furan-modified cashew phenolic resin has a heterocyclic structure with conjugated double bonds, and its performance is stable. As a structural unit of the condensation polymer, it can effectively improve Acid resistance, alkali resistance, solvent resistance and heat resistance of the resin. At the same time, the introduction of the furan ring increases the molecular weight of the polycondensate, and at the same time increases the distance between the hydroxymethylbenzene rings, reducing the steric hindrance of the methylol group in the further polycondensation process during thermal curing, so that the resin after thermal curing The cross-linking is more sufficient and the cross-linking density is higher, which promotes the formation of a network structure with high cross-linking density, and improves the perme...

Embodiment 1

[0030] Embodiment 1: (by weight part)

[0031] (1) The component proportions are: cardanol: 100 parts, formaldehyde: 32 parts, furfuryl alcohol: 10 parts, xylene: 80 parts, catalyst: zinc oxide 2 parts, ammonia water 6 parts.

[0032] (2) In the resin preparation process of the present invention, cardanol, formaldehyde, and catalyst are added in proportion to the reaction kettle, and reacted at 70°C-80°C for 1-2 hours; furfuryl alcohol is added, and reacted at 90°C-100°C for 1-2 hours; Then add 80-120 parts of xylene, heat up, and use an oil-water separation device to remove water until the temperature reaches 155-160°C and keep it for 1-2 hours to obtain the resin of the present invention.

Embodiment 2

[0033] Embodiment 2 (by weight):

[0034] (1) The proportions of the components in parts by weight are: cardanol: 140 parts, formaldehyde: 54 parts, furfuryl alcohol: 23 parts, xylene: 120 parts, catalyst: ammonia water 9 parts.

[0035] (2) The preparation method of this embodiment is the same as that of the embodiment (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com