Aqueous primer used for bicycles

A water-based, bicycle technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of not being suitable for bicycle coating process requirements, difficult to meet anti-corrosion and anti-rust requirements, and corrosion resistance can not meet anti-corrosion requirements, etc. Achieve the effect of improving boiling water resistance, improving anti-corrosion effect, and ensuring the performance of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 prepares waterborne epoxy acrylic resin

[0016] The water-based epoxy acrylic resin is made of epoxy resin with an epoxy equivalent of 500-1500g / mol, which accounts for 10-40% of the total weight of the resin, and is heated and dissolved with a solvent and partially aminated, and then mixed with acrylic acid, hydroxypropyl acrylate, Acrylic resin with an acid value of 50-200mgKOH / g, which is formed by free radical polymerization of butyl acrylate and styrene monomer, is prepared by heating together for catalytic esterification reaction. The specific operation is as follows:

[0017] ① Preparation of acrylic resin

[0018] Add 244 parts by weight of ethylene glycol butyl ether and 90 parts by weight of propylene glycol methyl ether into a 1000ml four-neck flask equipped with a thermometer, a stirring device and a condensation device, start stirring and heat up to a reaction temperature of 115°C, and 92.7 parts by weight of acrylic acid hydroxyl Propyl este...

Embodiment 2

[0021] Embodiment 2 prepares water-based closed type polyurethane curing agent resin A and B

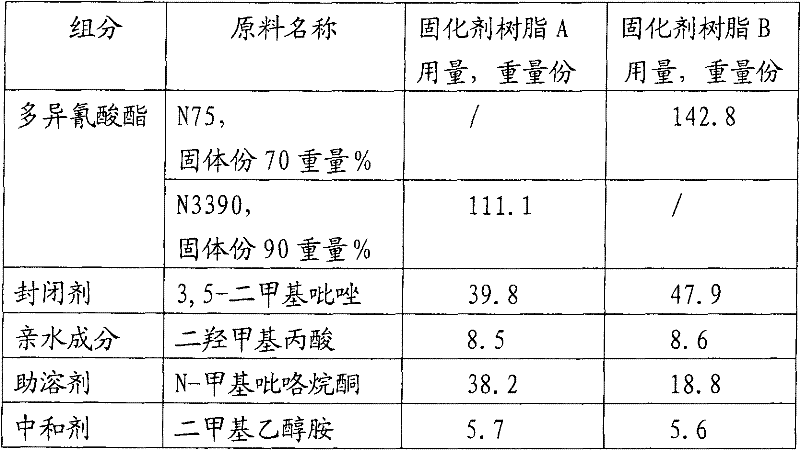

[0022] (1) The specific formula is shown in Table 1.

[0023] Table 1

[0024]

[0025] Note: N75 is 1,6-hexamethylene diisocyanate biuret produced by Bayer; N3390 is 1,6-hexamethylene diisocyanate trimer produced by Bayer.

[0026] (2) specific preparation method

[0027] According to the formula in Table 1, add polyisocyanate and co-solvent to the reaction vessel and adjust the temperature to 50°C, then add the blocking agent 3,5-dimethylpyrazole, keep the reaction for 2 hours, then raise the temperature to 60-80°C, Add the hydrophilic component dimethylolpropionic acid, keep it warm for 4 hours, then cool down to 50°C, add neutralizing agent dimethylolamine to neutralize, then dilute with deionized water to a solid content of 40% by weight, filter, Packaging respectively made water-based blocked polyurethane curing agent resins A and B, wherein the isocyanate group content o...

Embodiment 3

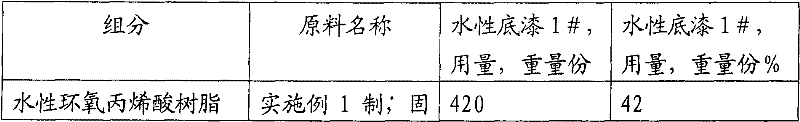

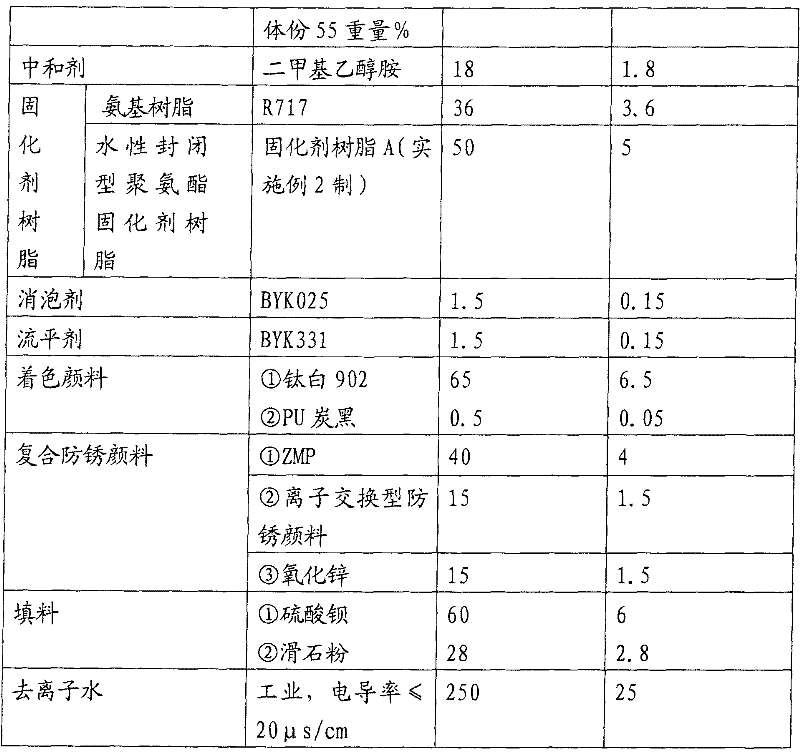

[0028] Embodiment 3 prepares bicycle water-based primer

[0029] (1) The formula water-based primer for bicycles is composed of the following components, in percentage by weight, and the dosage of each component is as follows:

[0030] Water-based epoxy acrylic resin 25-45, curing agent resin 2-10, neutralizer dimethylethanolamine 1-3, composite anti-rust pigment 2-10, coloring pigment and filler 5-20, defoamer 0.1-0.5, Leveling agent 0.1-0.5, deionized water 20-40, the sum of the contents of each component is 100%, the specific formula is shown in Table 2.

[0031] Table 2

[0032]

[0033]

[0034] Note: R717 is an amino resin product of INEOS;

[0035] BYK025 is a defoamer product of BYK Chemicals;

[0036] BYK331 is the leveling agent product of BYK Chemical Company;

[0037] Titanium dioxide 902 is DuPont's rutile titanium dioxide product;

[0038] PU carbon black is a carbon black product of Degussa;

[0039] ZMP is a modified zinc phosphate anti-rust pigment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com