Styrene modified polyvinyl acetate emulsion and preparation method

A polyvinyl acetate and styrene technology, which is applied in the field of styrene-modified polyvinyl acetate emulsion and its preparation, can solve the problems of difficult copolymerization, poor boiling water resistance and the like, and achieves simple process, low cost and stable system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

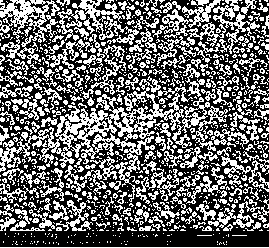

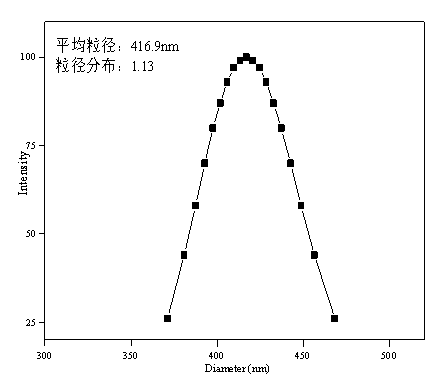

Image

Examples

Embodiment 1

[0031] Styrene modified polyvinyl acetate emulsion adhesive of the present invention is prepared from according to the raw material of following weight percent:

[0032] Deionized water: 58-62%; polyvinyl alcohol: 2-10%; mixed monomer 1: 20-35%; mixed monomer 2: 4-20%; compound emulsifier: 0.6-2%; pH buffer : 0.1~0.5%; Initiator: 0.1~1%.

[0033] Concrete preparation method is as follows:

[0034] (1) Reagent treatment

[0035] Dissolve the persulfate initiator at 40°C, filter, cool the filtrate with ice, crystallize out, filter, wash the crystals with ice-cold water, wash with BaCl 2 Solution check until the washing solution is free of precipitation. Dry the white columnar or plate-shaped crystals in a vacuum desiccator and store them for future use;

[0036] (2) Preparation of styrene-modified polyvinyl acetate emulsion

[0037] 1. Monomer mixing

[0038] Mixed monomer 1: mixed vinyl acetate and alkyl acrylate (the total amount of mixed monomer 1 is based on 100% by ma...

Embodiment 2

[0059] Styrene modified polyvinyl acetate emulsion adhesive (PVAc-1) of the present invention is prepared from according to the raw material of following weight percent:

[0060] Deionized water: 58.4%; polyvinyl alcohol: 2.5%; mixed monomer 1: 31.6%; mixed monomer 2: 5.8%; complex emulsifier: 1.2%; pH buffer: 0.3%; initiator: 0.2%.

[0061] Among them, mixed monomer 1 is formed by mixing vinyl acetate and butyl acrylate, and the proportion is 90% of vinyl acetate and 10% of butyl acrylate; mixed monomer 2 is formed by mixing styrene and butyl acrylate, and the proportion is It is 78% styrene and 22% butyl acrylate.

[0062] The compound emulsifier is alkylphenol polyoxyethylene ether and sodium lauryl sulfate, the ratio is 7:2; the initiator is potassium persulfate; the pH buffer is sodium bicarbonate; the polyvinyl alcohol is 1788 type.

[0063] Above-mentioned styrene-modified polyvinyl acetate emulsion adhesive is prepared according to the following method:

[0064] 1. M...

example 3

[0072] Styrene modified polyvinyl acetate emulsion adhesive (PVAc-2) of the present invention is prepared from according to the raw material of following weight percent:

[0073] Deionized water: 62%; polyvinyl alcohol: 2.7%; mixed monomer 1: 27.6%; mixed monomer 2: 5.2%; complex emulsifier: 1.9%; pH buffer: 0.4%; initiator: 0.2%.

[0074] Among them, mixed monomer 1 is formed by mixing vinyl acetate and butyl acrylate, and the proportion is 80% of vinyl acetate and 20% of butyl acrylate; mixed monomer 2 is formed by mixing styrene and butyl acrylate, and the proportion is It is 88% styrene and 12% butyl acrylate.

[0075] The composite emulsifier is alkylphenol polyoxyethylene ether and sodium dodecylsulfonate in a ratio of 2:1; the initiator is ammonium persulfate; the pH buffer is sodium carbonate; the polyvinyl alcohol is 1788 type.

[0076] Above-mentioned styrene-modified polyvinyl acetate emulsion adhesive is prepared according to the following method:

[0077] 1. Mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com