Method for preparing metallic nickel nano powder

A technology of nano-powder and metal nickel, which is applied in the field of nano-material preparation, can solve problems such as troublesome waste liquid treatment, unfavorable environmental protection, complicated equipment, etc., and achieve the effects of low production cost, uniform distribution, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

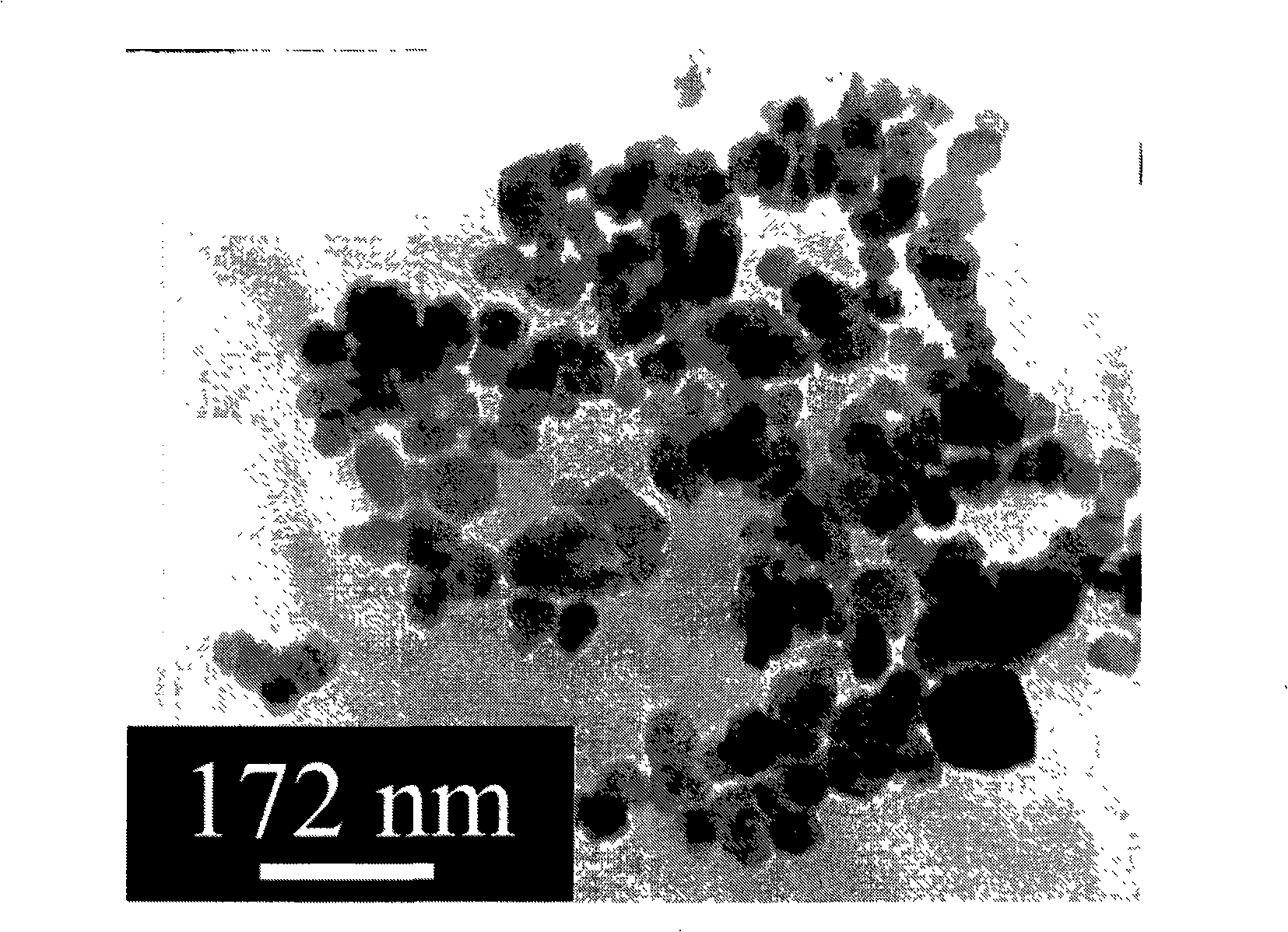

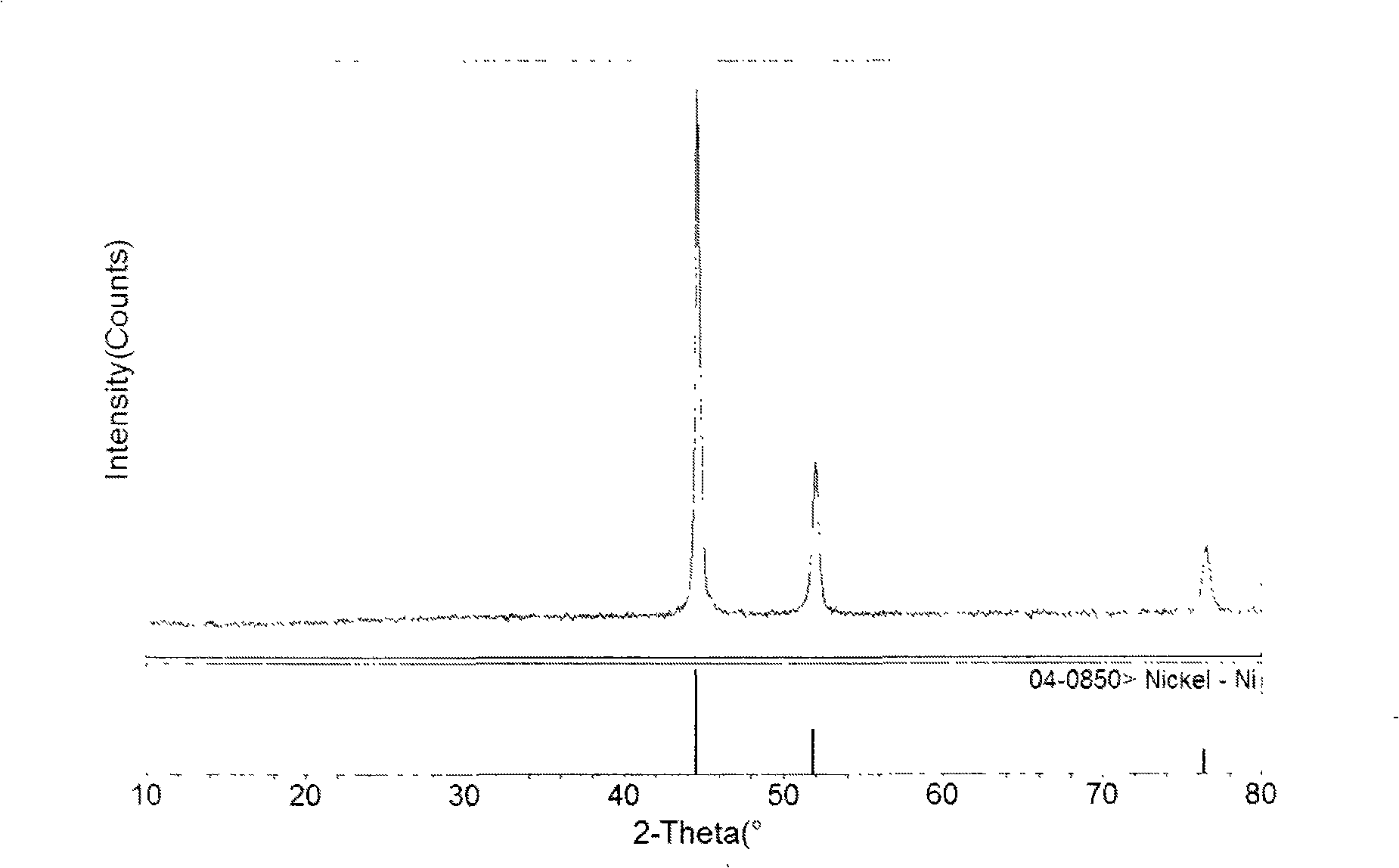

Image

Examples

Embodiment 1

[0014] At 20°C, mix nickel sulfate and Tween 20 according to the mass ratio of 1:0.15, then grind them in a mortar for 10 minutes until they are evenly mixed, then add metal aluminum powder, the molar mass ratio of aluminum powder and nickel sulfate is 1 : 1. The mixture was ground until it reacted, followed by grinding for 30 minutes, and left to stand for 0.5 hour to obtain a mixture containing nano-nickel powder. The obtained mixture containing nano-nickel powder is washed twice with 2M sodium hydroxide and distilled water respectively, and centrifuged; the cleaned nano-nickel powder can be vacuum-dried at 40°C. The obtained metal nickel powder has an average particle diameter of 40 nm.

Embodiment 2

[0016] At 20°C, mix nickel chloride and Tween 20 according to the mass ratio of 1:0.15, then grind them in a mortar for 10 minutes until they are evenly mixed, then add metal aluminum powder, the molar mass ratio of aluminum powder and nickel chloride It is 1.5:1. The mixture was ground until reacted and then ground for 30 minutes to obtain a mixture containing nano-nickel powder. The obtained mixture containing nano-nickel powder is washed twice with 2M sodium hydroxide and distilled water respectively, and centrifuged; the cleaned nano-nickel powder can be vacuum-dried at 40°C. The obtained metal nickel powder has an average particle diameter of 30 nm.

Embodiment 3

[0018] At 20°C, mix nickel nitrate and Tween 20 according to the mass ratio of 1:0.10, then grind them in a mortar for 10 minutes until they are evenly mixed, then add metal aluminum powder, the molar mass ratio of aluminum powder and nickel nitrate is 1 : 1. The mixture was ground until it reacted, followed by grinding for 30 minutes, and left to stand for 0.5 hour to obtain a mixture containing nano-nickel powder. The obtained mixture containing nano-nickel powder is washed twice with 2M sodium hydroxide and distilled water respectively, and centrifuged; the cleaned nano-nickel powder can be vacuum-dried at 40°C. The obtained metal nickel powder has an average particle diameter of 60 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com