Grinding disc filter screen structure for fruit and vegetable processing machine

A processing machine and filter screen technology, applied in the direction of household machinery, applications, household appliances, etc. for filtering food, can solve the problems of easy blocking of mesh holes by fibers, reduce the nutritional content of fruit puree, etc., and achieve the effect of maintaining nutritional content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

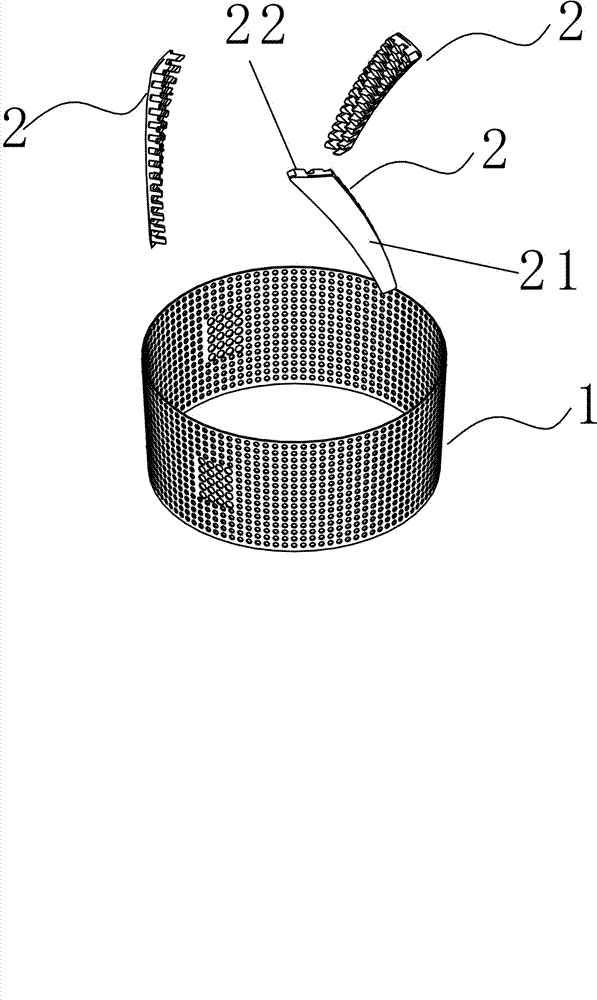

[0022] Embodiment 1: as figure 1 As shown, a grinding plate filter screen structure for a fruit and vegetable processing machine of the present invention includes a filter screen 1 and a blade 2 . Three blades 2 are arranged on the inner wall of the filter screen 1 . The number of blades 2 here can be set according to needs, and is not limited to three. That is, four or five, or even more, can be set as required. Each of the three blades 2 is in the shape of a sheet, and one of the surfaces 21 of the blade 2 is attached to the inner wall of the filter screen 1, and the other surface 22 is a rough grinding surface, that is, the surface 22 is provided with Files, these teeth are used to grind fruit. like figure 1 As shown, one of the longer two sides of the blade 2 is a blade surface, which can cut fruit. And the side of the blade 2 and the generatrix of the filter screen form a certain inclination angle. like figure 1 As shown, the filter screen 1 is in the shape of...

Embodiment 2

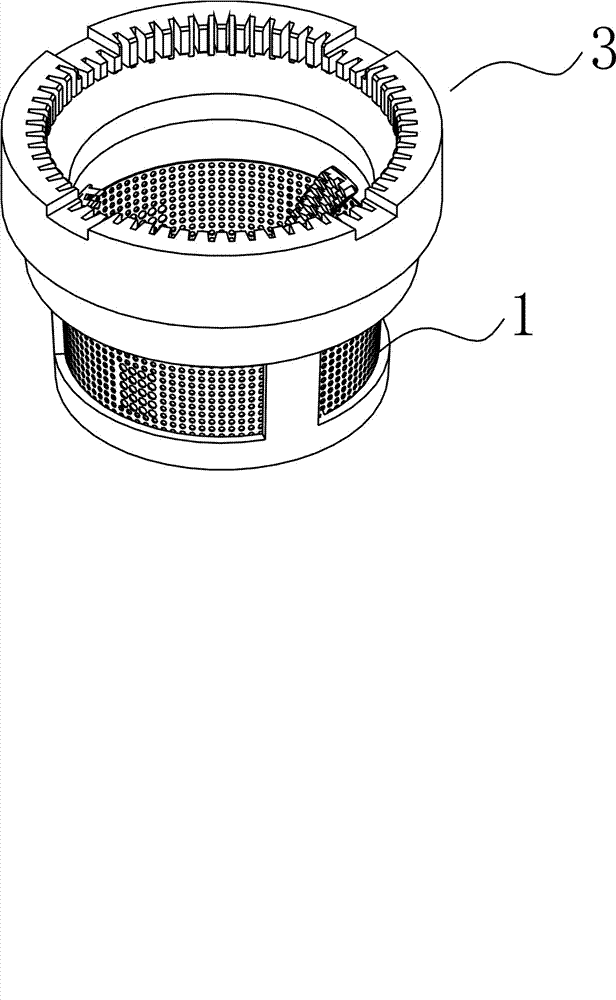

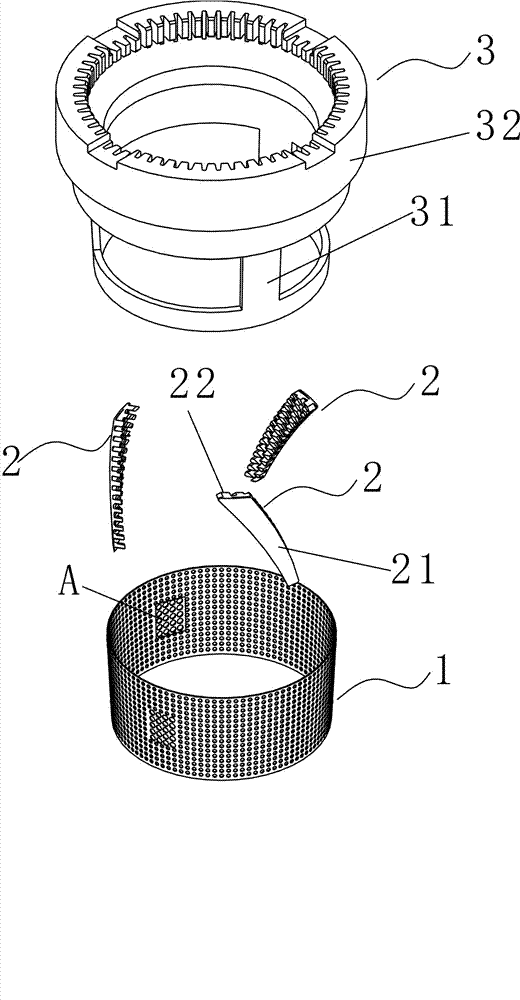

[0023] Embodiment 2: as figure 2 , image 3 and Figure 4 As shown, a millstone filter screen structure for a fruit and vegetable processing machine of the present invention includes a filter screen 1 , a blade 2 and a screen filter frame 3 . Three blades 2 are arranged on the inner wall of the filter screen 1 . The number of blades 2 here can be set according to needs, and is not limited to three. That is, four or five, or even more, can be set as required. Each of the three blades 2 is in the shape of a sheet, and one of the surfaces 21 of the blade 2 is attached to the inner wall of the filter screen 1, and the other surface 22 is a rough grinding surface, that is, the surface 22 is provided with Files, these teeth are used to grind fruit. like figure 1 As shown, one of the longer two sides of the blade 2 is a blade surface, which can cut fruit. like figure 1 As shown, the filter screen 1 is in the shape of a ring, and the screen holes are evenly distributed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com