Polishing composition, a method for producing same, and magnetic polishing method

A composition and magnetic grinding technology, which is applied in the direction of manufacturing tools, grinding devices, grinding machine tools, etc., can solve problems such as safety problems, reduced grinding performance of grinding compositions, and insufficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] One embodiment of the present invention will be described in detail. In addition, although the following embodiment shows an example of this invention, this invention is not limited to this embodiment. In addition, various changes and improvements can be added to the following embodiments, and the forms to which various changes and improvements have been added can also be included in the present invention.

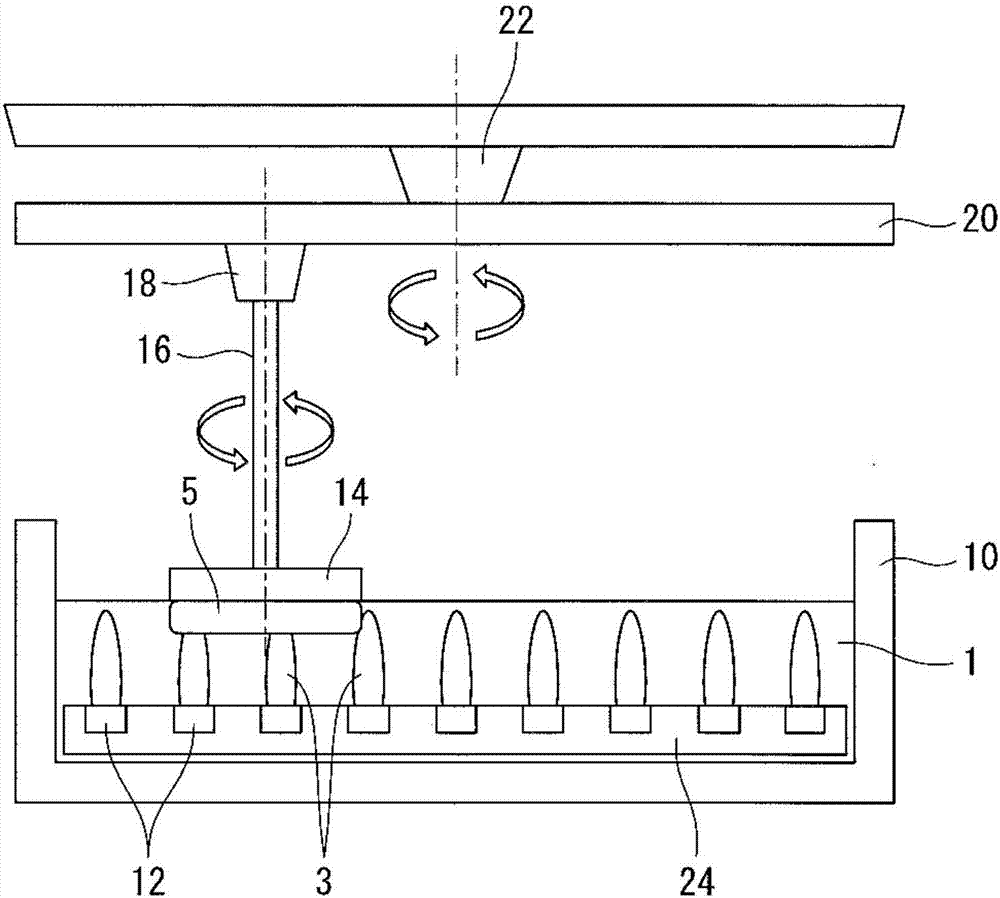

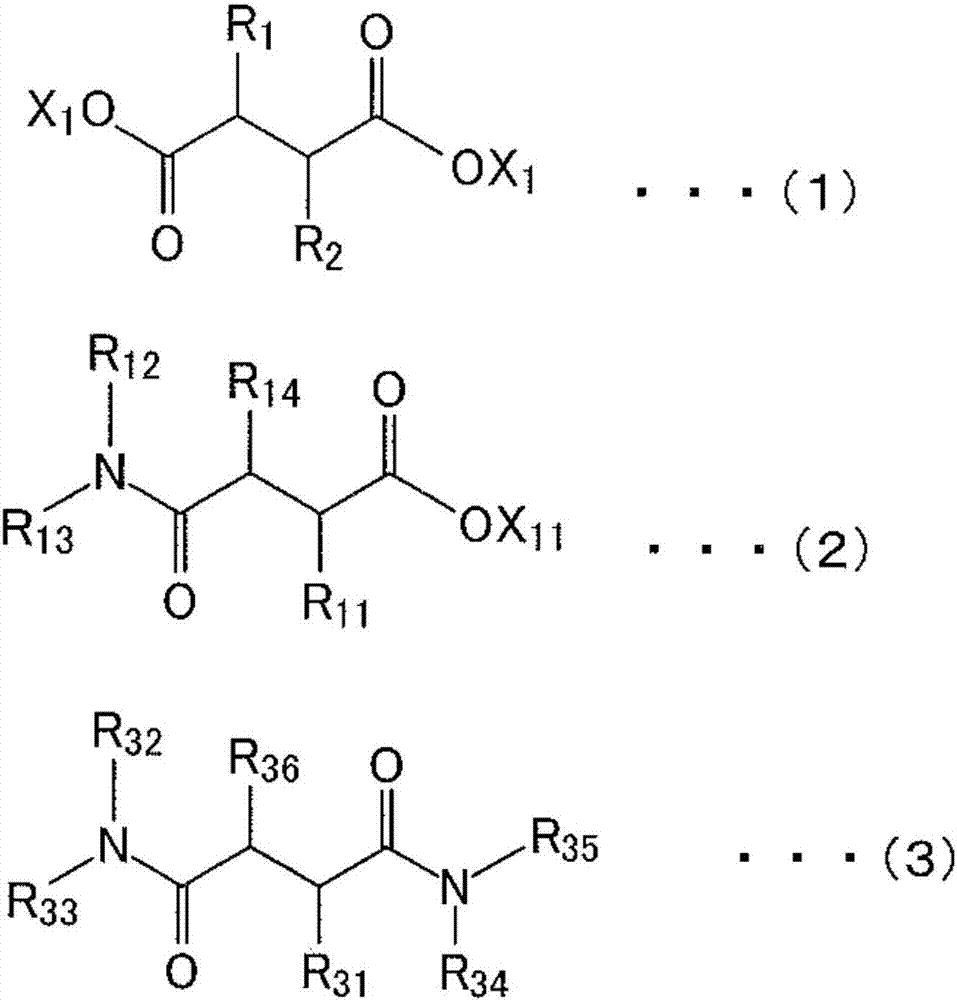

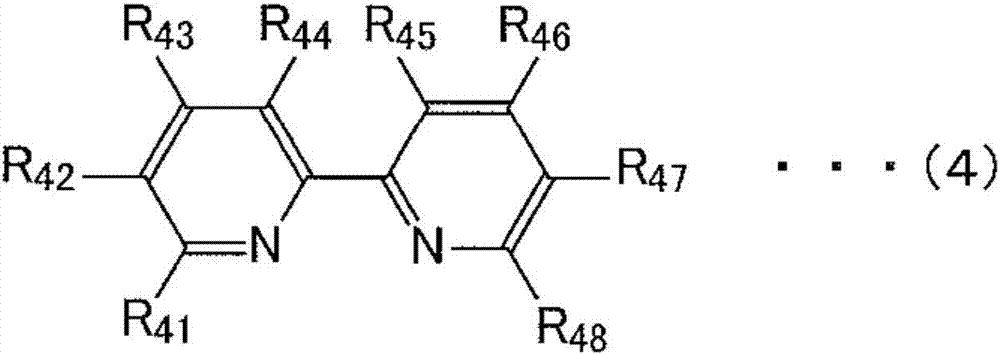

[0026] The polishing composition of the present embodiment contains magnetic particles, an antioxidant for suppressing oxidation of the magnetic particles, and water. When a magnetic field is applied to the polishing composition of the present embodiment, the magnetic particles functioning as abrasive grains are arranged in chains along the lines of magnetic induction to form magnetic particle clusters. Since the magnetic particle cluster functions as a polishing tool, the polishing composition of the present embodiment can be used in a magnetic polishing method. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com