Azacitidine freeze-drying powder injection and preparation method thereof

A technology of azacitidine and freeze-dried powder injection, applied in the field of azacitidine, can solve the problems of the influence of clinical medication safety and effectiveness, poor stability of azacitidine, increase of impurities during storage period, etc. Conducive to storage and ensure the effect of medication safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of azacitidine freeze-dried powder preparation

[0030] 1.1 Formation:

[0031] Azacitidine 100g

[0032] Mannitol 100g

[0033] Vitamin C 10g

[0034] Add water for injection to 3000ml

[0035] A total of 1000 pieces were made.

[0036] 1.2 Take the following steps to prepare:

[0037] a. According to the above preparation prescription, take 100g of azacitidine raw material, 100g of mannitol, and 10g of vitamin C, and dissolve them with 2400ml of water for injection;

[0038] b. Add activated carbon with 1% volume of the dissolved medicinal solution, decolorize, and filter to remove carbon;

[0039] c. Dilute to the prepared amount with the above-mentioned water for injection, measure the concentration of the medicinal solution, and the pH value of the medicinal solution ranges from 3.5 to 6.0;

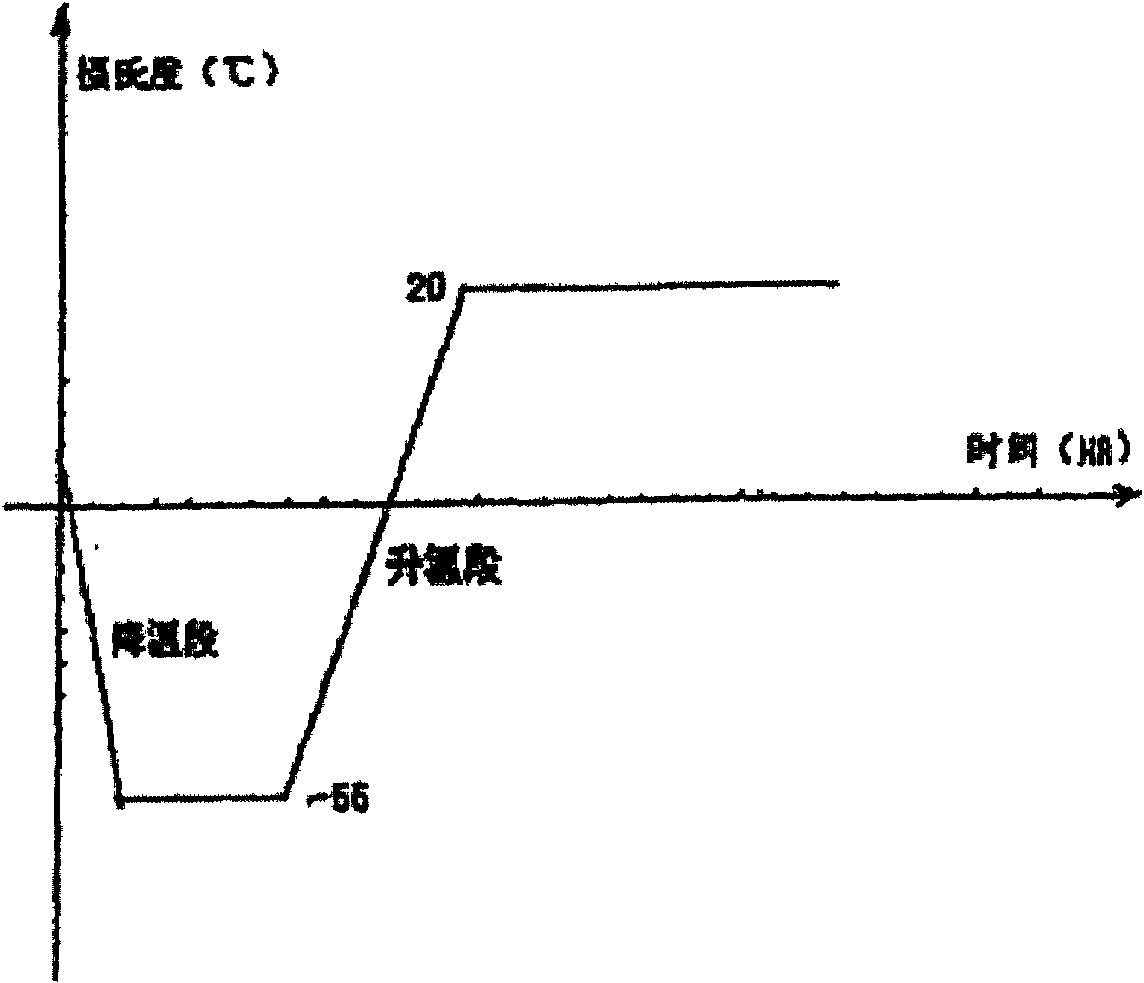

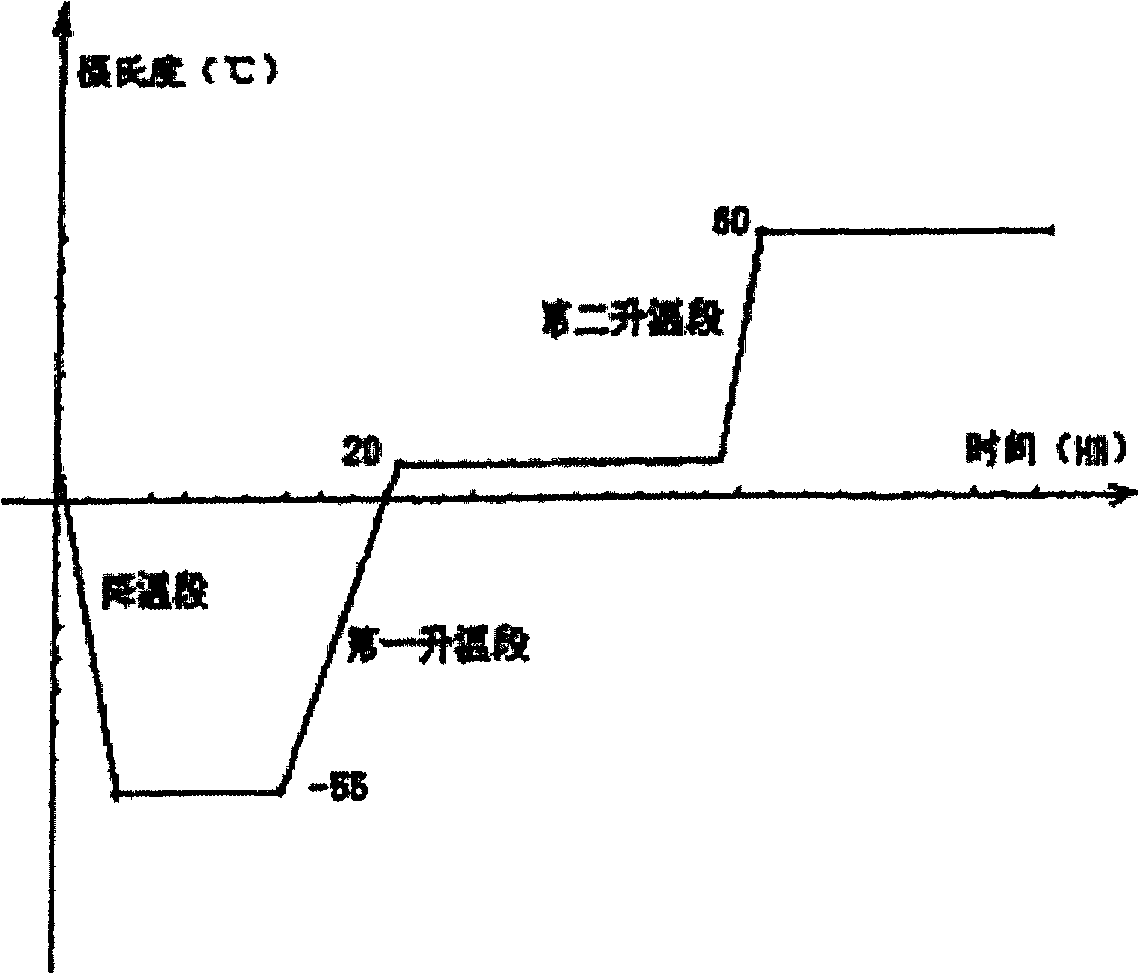

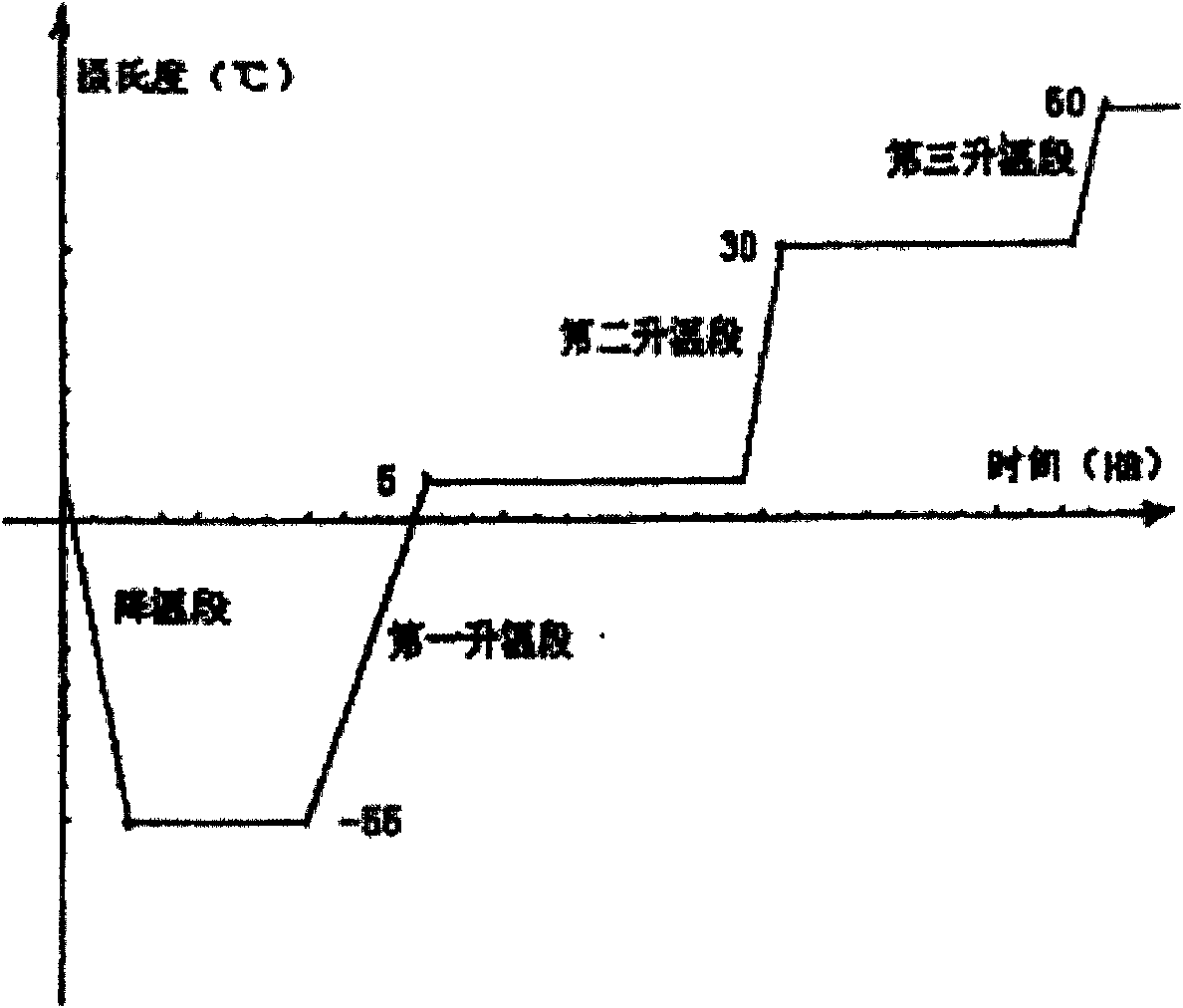

[0040] d. Filter and sterilize through a filter membrane to a liquid storage tank, sub-package, freeze-dry according to a preset temperature, crimp the cap,...

Embodiment 2

[0050] Preparation of azacitidine freeze-dried powder preparation

[0051] 2.1 Formation:

[0052] Azacitidine 100g

[0053] Mannitol 100g

[0054] Vitamin C 15g

[0055] Add water for injection to 2500ml

[0056] A total of 1000 pieces were made.

[0057] 2.2 Take the following steps to prepare:

[0058] a. According to the above preparation prescription, take 100g of azacitidine raw material, 100g of mannitol, and 15g of vitamin C, and dissolve them with 2000ml of water for injection;

[0059] b. Add 0.8% active carbon of the volume of the dissolved medicinal solution for decolorization, and filter to remove carbon;

[0060] c. Dilute to the prepared amount with the above-mentioned water for injection, measure the concentration of the medicinal solution, and the pH value of the medicinal solution ranges from 3.5 to 6.0;

[0061] d. Filter and sterilize through a filter membrane to a liquid storage tank, sub-package, freeze-dry according to a preset temperature, crimp ...

Embodiment 3

[0071] Preparation of azacitidine freeze-dried powder preparation

[0072] 3.1 Formation:

[0073] Azacitidine 100g

[0074] Mannitol 100g

[0075] Vitamin C 28g

[0076] Add water for injection to 4000ml

[0077] A total of 1000 pieces were made.

[0078] 3.2 Take the following steps to prepare:

[0079] a. According to the above prescription, take 100g of azacitidine raw material, 100g of mannitol, and 28g of vitamin C, and dissolve them with 3200ml of water for injection;

[0080] b. add 1.5% activated carbon of water for injection for decolorization, and filter to remove carbon;

[0081] c. Dilute to the prepared amount with the above-mentioned water for injection, measure the concentration of the medicinal solution, and the pH value of the medicinal solution ranges from 3.5 to 6.0;

[0082] d. Filter and sterilize through a filter membrane to a liquid storage tank, sub-package, freeze-dry according to a preset temperature, crimp the cap, and pack.

[0083] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com