Soft magnetic material annealing thermal treatment method

A technology of annealing heat treatment and soft magnetic materials, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of unadjustable annealing temperature, affecting soft magnetic properties, power consumption and time consumption, etc., to improve annealing efficiency and reduce correction Tenacity, sensitivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

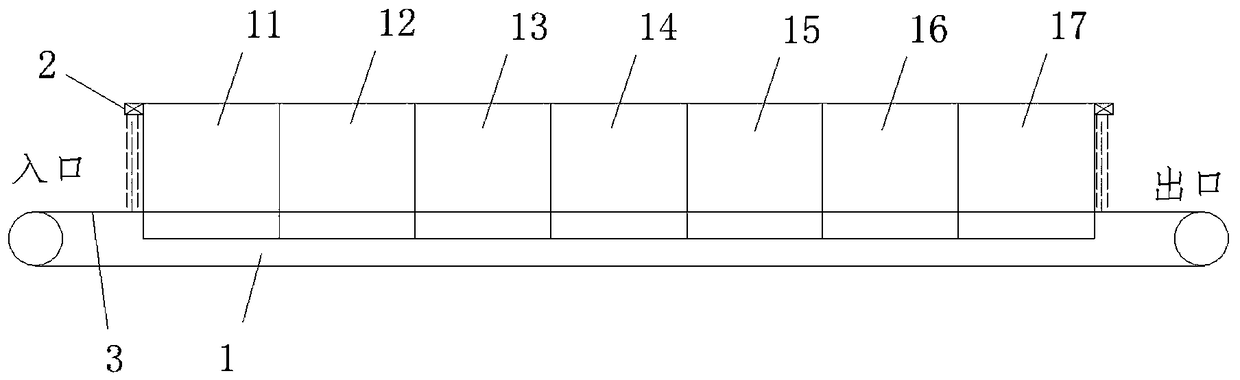

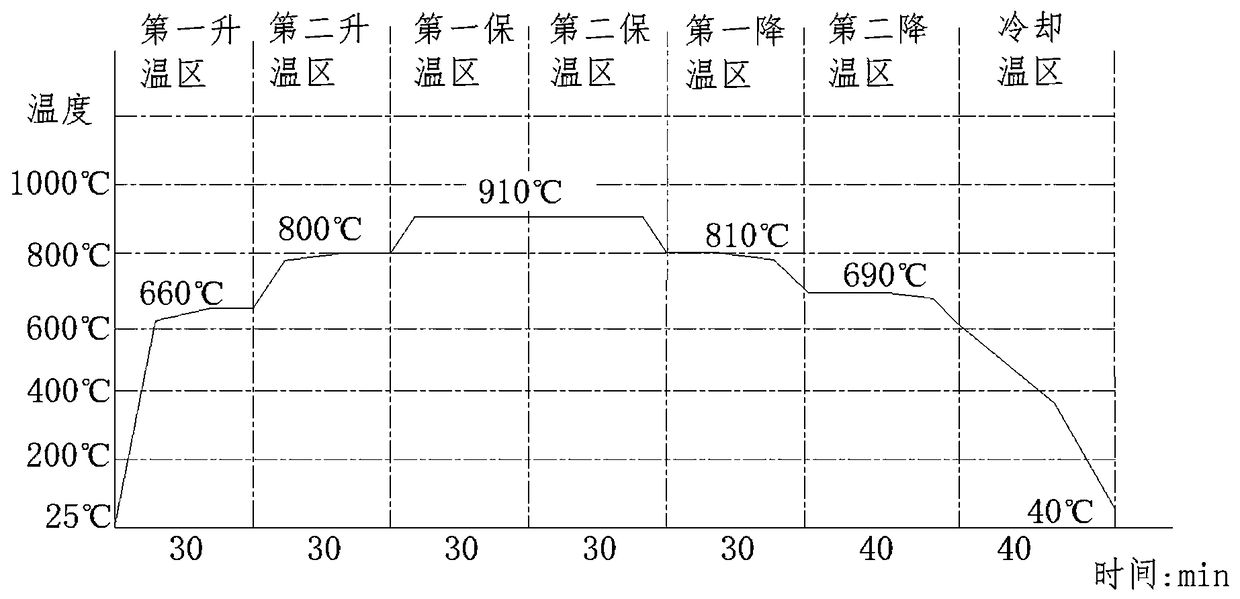

[0022] Such as figure 1 As shown, the present invention provides a kind of soft magnetic material annealing heat treatment method, comprises the following steps:

[0023] S1. Carry out derusting treatment on soft magnetic materials; during derusting treatment, use an ultrasonic cleaning machine to immerse the soft magnetic materials in derusting liquid and ultrasonically clean them for 10 minutes. The mass ratio of water and derusting agent in derusting liquid is 100:5 ;

[0024] S2. Carry out degreasing and antirust treatment on the soft magnetic material; during deoiling and antirust treatment, use an ultrasonic cleaner to immerse the soft magnetic material in the deoiling and antirust liquid for ultrasonic cleaning for 10 minutes. The mixture of antirust agent, the mass ratio of degreasing agent to antirust agent is 100:1.5;

[0025] S3. Dry the soft magnetic material; use a drying oven for drying, the drying temperature is 60±10°C, and the drying time is 1h±10min;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com